Recommended Use:

AM track-mounted screening plant has a variety of screen decks and comes with large scope of application. Different screen decks can be selected as per different raw materials and finished product particle size requirements. It can screen 4 kinds of finished materials and the processing capacity ranges from 100t/h to 350t/h.

- Product Details

- {{item.text}}

Quick Details

-

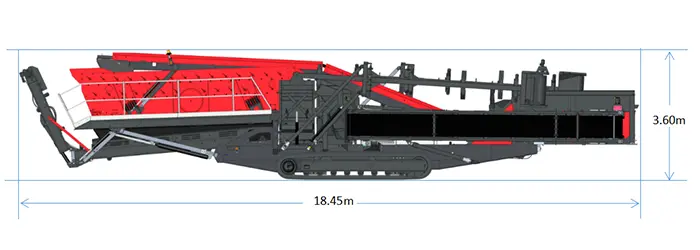

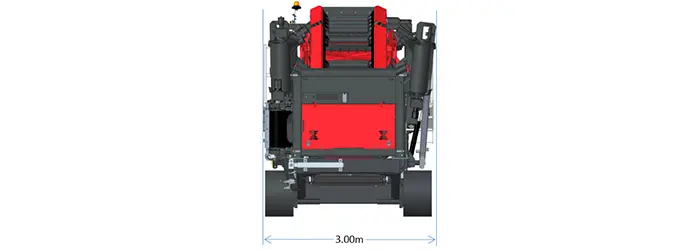

Dimension(L*W*H):

-

18.45m*3m*3.6m

-

Weight:

-

35000 KG

-

Product name:

-

Mobile Crawler Screening Plant AM3600H

-

Engine Power:

-

93kW

-

Engine:

-

CUMMINS Diesel Engine

-

Model:

-

AM3600H

-

Model Weight:

-

35T

-

Feeder Belt Width:

-

1200mm

-

Feeder Hopper Volume:

-

8m³

-

Screen Box Layer:

-

3

-

Screen Boxes Width:

-

6.10m*1.50m

-

Screen Box Meshes Type:

-

Side tensioned mesh

Quick Details

-

Type:

-

Vibrating screen

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ACE

-

Dimension(L*W*H):

-

18.45m*3m*3.6m

-

Weight:

-

35000 KG

-

Product name:

-

Mobile Crawler Screening Plant AM3600H

-

Engine Power:

-

93kW

-

Engine:

-

CUMMINS Diesel Engine

-

Model:

-

AM3600H

-

Model Weight:

-

35T

-

Feeder Belt Width:

-

1200mm

-

Feeder Hopper Volume:

-

8m³

-

Screen Box Layer:

-

3

-

Screen Boxes Width:

-

6.10m*1.50m

-

Screen Box Meshes Type:

-

Side tensioned mesh

Dear customers,

In order to provide you with a fast and accurate quote, please tell us the following information:

1. The type and quantity you need.

2. Machine capacity and configuration.

3. Your target price.

4. The appearance of the machine can be customized.

There is more information that you are more concerned about. We are an independent research and development dealer integrating industry and trade. We can produce according to your needs. As long as you can confirm the model information you need,we can ship it to you immediately. We require 30% of the amount as deposit to place an order. Click the link for more details.

1. The type and quantity you need.

2. Machine capacity and configuration.

3. Your target price.

4. The appearance of the machine can be customized.

There is more information that you are more concerned about. We are an independent research and development dealer integrating industry and trade. We can produce according to your needs. As long as you can confirm the model information you need,we can ship it to you immediately. We require 30% of the amount as deposit to place an order. Click the link for more details.

Products Description

Mobile Crawler Screening Plant

Due to its optimized dynamic design and advanced technology it adopts, the AM series mobile screening plant has formed a more stable, reliable, and high-efficiency screening capability, suited to screen almost all-natural materials and building residues.It is already a piece of ideal equipment for independent screening or multi-stage mobile screening.

Technical Parameters

|

Model

|

|

|

|

Model

|

AM3600H

|

|

|

Model Weight

|

35t

|

|

|

Overall Dimensions(L*W*H)

|

18.45m*3m*3.6m

|

|

|

Engine

|

|

|

|

Engine

|

CUMMINS Diesel Engine

|

|

|

Engine Power

|

93kW

|

|

|

Feeder

|

|

|

|

Belt Width

|

1200mm

|

|

|

Hopper Volume

|

8m³

|

|

|

Screen Box

|

|

|

|

Layer

|

3

|

|

|

Screen Boxes Width

|

6.10m×1.50m

|

|

|

Meshes Type

|

Side tensioned mesh

|

|

|

Main & Fines Aggregate Conveyor

|

|

|

|

Belt Width

|

1200mm

|

|

|

Oversize Plus Conveyor

|

|

|

|

Belt Width

|

650mm

|

|

|

Belt Type

|

Chevron conveyor belt

|

|

|

Oversize & Medium Aggregate Side Conveyor

|

|

|

|

Belt Width

|

800mm

|

|

|

Belt Type

|

Chevron conveyor belt

|

|

|

Other Configurations

|

|

|

|

Galvanised Catwalk

|

c/w handrails, steps and access ladders

|

|

|

Heavy-duty Crawler Belt Width

|

500mm

|

|

|

Handheld Crawler Controller

|

3m wire

|

|

|

Emergency Stop Devices

|

3

|

|

|

Anti-wear Hydraulic Oil

|

- ISO 46

|

|

|

Paint & Decal

|

RAL5012 Blue, Grey Frame

|

|

Transport Dimensions

Transport Dimensions

Description

1. The processing capacity of the screener is determined by numerous factors. The most important factors include feed grain shape, end-product grain shape, and the humidity content.

2. Standard configuration: manual control, wireless remote control.

3. Optional: Diesel-electric drives, dust-removal spraying system.

4. AM3600H mobile screening plant adopts hydraulic drive technology.

1. The processing capacity of the screener is determined by numerous factors. The most important factors include feed grain shape, end-product grain shape, and the humidity content.

2. Standard configuration: manual control, wireless remote control.

3. Optional: Diesel-electric drives, dust-removal spraying system.

4. AM3600H mobile screening plant adopts hydraulic drive technology.

For more parameter information, click the link to contact us

Main Feature

1.

It adopts intelligent wireless remote control technology and can walk on its own crawler. It can be operated remotely to get on and off the flatbed trailer to realize rapid relocation.

2. The vibrating screen can be raised and lowered by hydraulic pressure, which is convenient for maintenance and replacement of the screen and is also convenient for transportation.

3. The screener can screen up to 4 kinds of the final products, and each finished product conveyor belt can be hydraulically folded so as to realize the whole machine transportation.

4. It is a complete screening system before leaving the factory, and can be quickly put into production without on-site

installation and commissioning.

5. According to the customer's needs for screening materials, a plate-type feeding system can be selected to achieve the special material screening.

6. Word famous key devices are employed, Strickland track, Bonfiglioli /Brevini/Eaton drive motor, Cummins diesel engine,

Schneider electrical elements, Eaton hydraulic plunger pump, Omron remote controller, etc. Other than these, AM series plant is equipped with hydraulic motor on belt conveyor and feeder. Performance, service life and value of the crusher is guaranteed.

2. The vibrating screen can be raised and lowered by hydraulic pressure, which is convenient for maintenance and replacement of the screen and is also convenient for transportation.

3. The screener can screen up to 4 kinds of the final products, and each finished product conveyor belt can be hydraulically folded so as to realize the whole machine transportation.

4. It is a complete screening system before leaving the factory, and can be quickly put into production without on-site

installation and commissioning.

5. According to the customer's needs for screening materials, a plate-type feeding system can be selected to achieve the special material screening.

6. Word famous key devices are employed, Strickland track, Bonfiglioli /Brevini/Eaton drive motor, Cummins diesel engine,

Schneider electrical elements, Eaton hydraulic plunger pump, Omron remote controller, etc. Other than these, AM series plant is equipped with hydraulic motor on belt conveyor and feeder. Performance, service life and value of the crusher is guaranteed.

Main Components

Engine and Cooling System

The globally well-known engine is employed, and its strong power and excellent performance will make this fully hydraulic machine more outstanding

Control System

Schneider electrical elements and Omron's PLC ensure stable performance of the control system. It has the function of fast fault diagnosis as well

Feeding Unit

Foldable, self-locking, simple and fast loading, safe initial operation

Return Screen

Bring oversized grains back to the feeding unit and make them crushed again

Belt Conveyor

Integrated belt conveyor, folding, hydraulic control

Maintenance Platform

A platform is provided to help gain access to the crusher and the powerpack, and do inspection and maintenance work

Remote Controller

All components and functions can be controlled easily via this hand-hold remote controller

STRICKLAND Track

British STRICKLAND track, sturdy, stable and durable, allow equipment to move flexibly at the jobsite

Hot Selling Products

Factory Profile

Professional Crushing Equipment Manufacturer

ACE Group has professional design engineers and experienced service engineers and is able to produce high-end crushing equipment and provide thoughtful after-sale service to cater to clients every requirement. We supply integrated combination solutions for crushing and screening on a variety of occasions as well.

In addition, ACE Group offers integrated plant which combines crusher plant with asphalt plant, concrete plant, prefabrication plant, and other construction material production plants.

Stone Crusher Plant Manufacture Base of ACE Group

Workshop for Manufacturing Stone Crusher, the Core Part of Stone Crushing Plant

We offer integrated solutions for stone crushing in a variety of industries

Construction Case

Crawler Impact Crusher Plant AMI1213 + Crawler Mobile Screening Plant, mainly process brittle aggregates

Crawler Impact Crusher Plant AMI1213 + Crawler Mobile Screening Plant AM3600H, 150-350t/h processing capacity

Fully Hydraulic Crawler Cone Crusher Plant AMC300 + Crawler Mobile Screening Plant AM3600H, For secondary crushing of high-hardness and highly abrasive rock minerals.

A Combination Consisting Of Crawler Cone Crusher Plant and Crawler Mobile Screening Plant, 100-300t/h processing capacity, water spray and dust reduction system

Certificate

Q: How to heat the asphalt?

A1: It's heated by heat conducting oil furnace and direct heating asphalt tank.

Q: How about the difference between a direct heat asphalt tank and a thermal oil asphalt tank?

A2: Direct heat asphalt tank belongs to the ordinary tank, with no heat conduction oil system, and the price is relatively

cheap,which is also called “tank in a tank”. Asphalt is heated by the small tank inside the tank, without any heat conduction oil system. Heat-conducting oil furnace type asphalt tank used an oil heat-conducting oil system, and coiled tubing for high heating speed, and all the oil can be pumped clean.

Q: How to choose the right machine for project?

A3: According to the capacity require per day, need to work how many days, how long destination site, etc.Engineers online will provide service to help you choose the right model also.

Q: What is the delivery time?

A4: 20-40 days after receiving advance payment.

Q: What are the payment terms?

A5: T/T, L/C, Credit card (for spare parts) are all accept.

Q: What kind of trade terms available from your side?

A. We can deal by EXW, FCA, FOB, CFR, DAP. CIF, DDP. etc.

Q: How to guarantee the trade safety if I made the payment?

A. We can deal on Alibaba by trade assurance order, so that both parties can be guaranteed.

Q: What's your supportive policy for distributors in overseas market?

A. We support in many aspects including marketing,promotion, product development/improvements, service training, advertising, etc.

Q: If I have other questions, whom should I ask?

A. You can contact us here online, our sales will respond within 10 mins.

A1: It's heated by heat conducting oil furnace and direct heating asphalt tank.

Q: How about the difference between a direct heat asphalt tank and a thermal oil asphalt tank?

A2: Direct heat asphalt tank belongs to the ordinary tank, with no heat conduction oil system, and the price is relatively

cheap,which is also called “tank in a tank”. Asphalt is heated by the small tank inside the tank, without any heat conduction oil system. Heat-conducting oil furnace type asphalt tank used an oil heat-conducting oil system, and coiled tubing for high heating speed, and all the oil can be pumped clean.

Q: How to choose the right machine for project?

A3: According to the capacity require per day, need to work how many days, how long destination site, etc.Engineers online will provide service to help you choose the right model also.

Q: What is the delivery time?

A4: 20-40 days after receiving advance payment.

Q: What are the payment terms?

A5: T/T, L/C, Credit card (for spare parts) are all accept.

Q: What kind of trade terms available from your side?

A. We can deal by EXW, FCA, FOB, CFR, DAP. CIF, DDP. etc.

Q: How to guarantee the trade safety if I made the payment?

A. We can deal on Alibaba by trade assurance order, so that both parties can be guaranteed.

Q: What's your supportive policy for distributors in overseas market?

A. We support in many aspects including marketing,promotion, product development/improvements, service training, advertising, etc.

Q: If I have other questions, whom should I ask?

A. You can contact us here online, our sales will respond within 10 mins.

Hot Searches