- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

6690*700*1400 mm

-

Weight:

-

5000 KG

-

Application fields:

-

Marshmallow Making

-

Raw material:

-

candy

-

Name:

-

Marshmallow Production Line

-

Usage:

-

Cotton Candy Making

-

Material:

-

304 Stainless Steel

-

Capacity:

-

100-500kg/h

-

MOQ:

-

1 Set

-

Advantage:

-

Easy Operation High Efficiency

-

Function:

-

Multifunctional

-

Application:

-

Food Industry

-

Automatic Grade:

-

Automatic

-

Key Machines:

-

Mixer

Quick Details

-

Model Number:

-

HNOC-MPL-02

-

Brand Name:

-

HNOC

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

6690*700*1400 mm

-

Weight:

-

5000 KG

-

Application fields:

-

Marshmallow Making

-

Raw material:

-

candy

-

Name:

-

Marshmallow Production Line

-

Usage:

-

Cotton Candy Making

-

Material:

-

304 Stainless Steel

-

Capacity:

-

100-500kg/h

-

MOQ:

-

1 Set

-

Advantage:

-

Easy Operation High Efficiency

-

Function:

-

Multifunctional

-

Application:

-

Food Industry

-

Automatic Grade:

-

Automatic

-

Key Machines:

-

Mixer

Product Description

Introduction

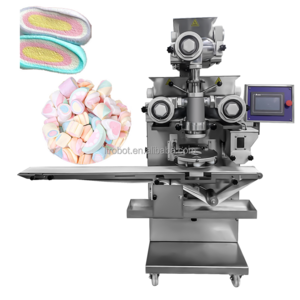

The fully automatic cotton candy inflatable stirring and beating machine starts from cooling and stirring to high-speed beating. The entire system consists of a pre mixing system, a beating system, a conveying system, a refrigeration system, and a control system. It can complete continuous high-speed beating of cotton candy or cake raw pulp in a short time, and automatically transport the beaten pulp to the forming machine through the automatic conveying system.

Application

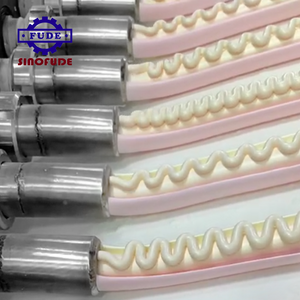

By changing the components, various types of marshmallows can be produced, such as bar shaped dual color, block shaped dot shaped, jam chocolate sandwich, etc.

Features

1.

The cotton candy production line adopts advanced computer control systems, which can meet the safety requirements of various enterprises.

2.

Different types of cotton candy can be customized according to production requirements to meet the taste preferences of different consumers.

3.

Adopting advanced automation technology can improve production efficiency and greatly enhance the market competitiveness of enterprises.

4.

Adopting advanced energy-saving technologies can effectively reduce energy consumption and greatly save costs.

Finished Product Display

Parameter

|

Model

|

HNOC-150

|

HNOC-300

|

HNOC-450

|

HNOC-600

|

|

standard production volume(kg/hour)

|

150

|

300

|

450

|

600

|

|

The sugar levels

|

2-6g

|

2-6g

|

2-6g

|

2-6g

|

|

pouring rate

|

45-55n/min

|

45-55n/min

|

45-55n/min

|

45-55n/min

|

|

Steam demand

|

0.2m³/min,

0.4-0.6Mpa |

0.2m³/min,

0.4-0.6Mpa |

0.2m³/min,

0.4-0.6Mpa |

0.2m³/min

,0.4-0.6Mpa |

|

Work environment requirements

|

Temperature:20-25℃

humidity :55% |

Temperature:20-25℃

humidity :55% |

Temperature:20-25℃

humidity :55% |

Temperature:20-25℃

humidity :55% |

|

Total Power

|

18kw/380V

|

27kw/380V

|

34kw/380V

|

38kw/380V

|

|

Overall length

|

15m

|

17m

|

17m

|

20m

|

|

Overall weight

|

3500kg

|

4000kg

|

4500kg

|

5000kg

|

Product Details

Product Photograph

Related Products

Hot Searches