- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±1%

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Fillex

-

Weight:

-

2000 KG

-

Capacity:

-

3000-48000BPH

-

Filling Technology:

-

Negative Pressure Filling

-

Bottle type:

-

Round Bottle Square Bottle

-

Bottle Height:

-

160-320mm

-

Bottle diameter:

-

50-120mm

-

Suitable for:

-

Carbonated Drink Filling Line

-

Advantage:

-

Easy Control/ High Accuracy

-

Material:

-

SUS 304/ 316

-

Filling Nozzles:

-

Customized Nozzle

-

Control:

-

PLC+ Touch Screen

Quick Details

-

Machinery Capacity:

-

8000BPH, Other, 12000BPH, 6000BPH, 20000BPH

-

Packaging Material:

-

Plastic, Metal, Glass

-

Filling Material:

-

Beer, Other

-

Filling Accuracy:

-

±1%

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Fillex

-

Weight:

-

2000 KG

-

Capacity:

-

3000-48000BPH

-

Filling Technology:

-

Negative Pressure Filling

-

Bottle type:

-

Round Bottle Square Bottle

-

Bottle Height:

-

160-320mm

-

Bottle diameter:

-

50-120mm

-

Suitable for:

-

Carbonated Drink Filling Line

-

Advantage:

-

Easy Control/ High Accuracy

-

Material:

-

SUS 304/ 316

-

Filling Nozzles:

-

Customized Nozzle

-

Control:

-

PLC+ Touch Screen

Products Description

Automatic Carbonated Soft Drink Filling Machine

The carbonated drinking filling machine could be separated to 3 modules. The height of the bottle-out conveyor is adjustable.

Bottles are conveyed to rinser, filler and capper through starwheel and conveyed out finally through bottle-out conveyor. Equip with alarm device for bottle block, bottle absence, cap absence and overload. The machine meets the national food hygienic standard, with high automation and easy to operate.

Features:

▶

All parts contacting with beverages adopt top grade stainless steels whose surfaces are polished till smooth for easy rinsing.

The sealing materials are EPDM rubber.

▶ Adopt PLC as center control, make use of pressure transmitter and electromagnetism pneumatic valve to measure liquid level.

keep balance of filling pressure to insure stable liquid level.

▶ Adopt new type filling valves which are especially designed for plastic bottles. The returned air and the liquid in filling.

tank are insulated to insure cleanliness of the filled beverages.

▶ Adopt advanced magnet clutches for capping with adjustable torsional moment to insure capping safely and reliably.

The sealing materials are EPDM rubber.

▶ Adopt PLC as center control, make use of pressure transmitter and electromagnetism pneumatic valve to measure liquid level.

keep balance of filling pressure to insure stable liquid level.

▶ Adopt new type filling valves which are especially designed for plastic bottles. The returned air and the liquid in filling.

tank are insulated to insure cleanliness of the filled beverages.

▶ Adopt advanced magnet clutches for capping with adjustable torsional moment to insure capping safely and reliably.

Product Paramenters

|

Model

|

14-12-5

|

16-16-5

|

24-24-8

|

32-32-8

|

40-40-10

|

50-50-10

|

|||||

|

Capacity

|

3,000

|

5,000

|

8,000

|

12,000

|

15,000

|

18,000

|

|||||

|

Suitable to Bottle

Shape

|

Round and Square container Bottle Diameter : 50-120mm

Bottle Height : 160-320mm

|

|

|

|

|

|

|||||

|

Drive Motor

|

2.42

|

3.12

|

3.92

|

3.92

|

5.87

|

7.87

|

|||||

Details Images

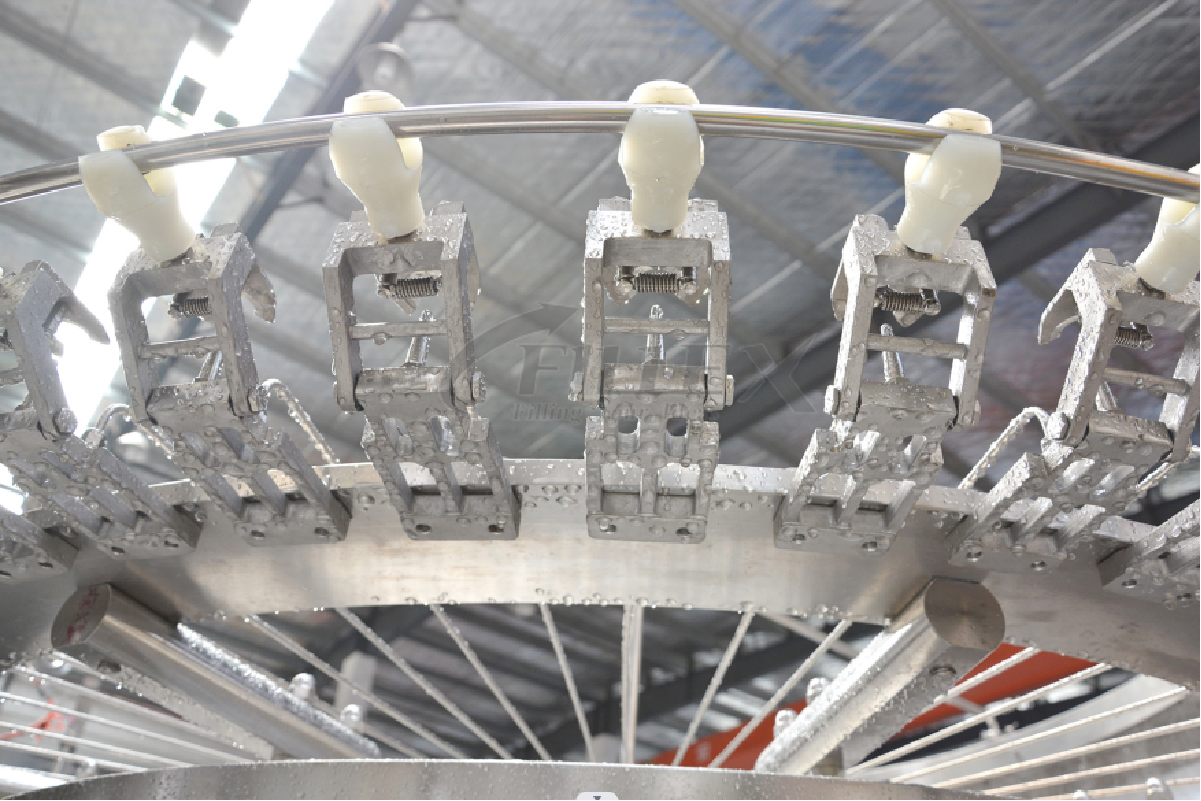

Washing Part

▶

Enhanced food safety

▶

Optimum uptime: 30% reduction in changeover and maintenance downtime

▶

Hygiene improvement through volume control and contactless filling

Filling Part

▶

High precision filling nozzle

▶

Filling volume adjustable in fine rank, same liquid level after filling

▶

Efficient spray nozzle rinse thoroughly and save water for flushing

Capping Part

▶

Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

▶

Automatic stop when lack of bottle

Hot Searches