- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Coal Dust Briquettes Machine

-

Dimension(L*W*H):

-

2.5*2*2.1m

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

roller material:

-

chromium-molybdenum steel

-

raw material:

-

iron, copper, coal, scale, silicon-manganese alloys, lime powder, etc

-

Name:

-

Coal Dust Briquettes Machine

-

package:

-

playwood case

-

the shape of briquettes:

-

round, square, circle,heart -shap

-

Installation:

-

Under our engineer's guide

-

Roll diameter::

-

290-520mm

-

Certification:

-

CE/BV/ISO

Quick Details

-

Weight (KG):

-

11000

-

Production Capacity:

-

1.5-2.5t/hour

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Coal Dust Briquettes Machine

-

Dimension(L*W*H):

-

2.5*2*2.1m

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

roller material:

-

chromium-molybdenum steel

-

raw material:

-

iron, copper, coal, scale, silicon-manganese alloys, lime powder, etc

-

Name:

-

Coal Dust Briquettes Machine

-

package:

-

playwood case

-

the shape of briquettes:

-

round, square, circle,heart -shap

-

Installation:

-

Under our engineer's guide

-

Roll diameter::

-

290-520mm

-

Certification:

-

CE/BV/ISO

High Pressure Coal Dust Briquettes Making Machine/Iron Powder Briquette Making Equipment/ Sponge Iron Briquette Machine

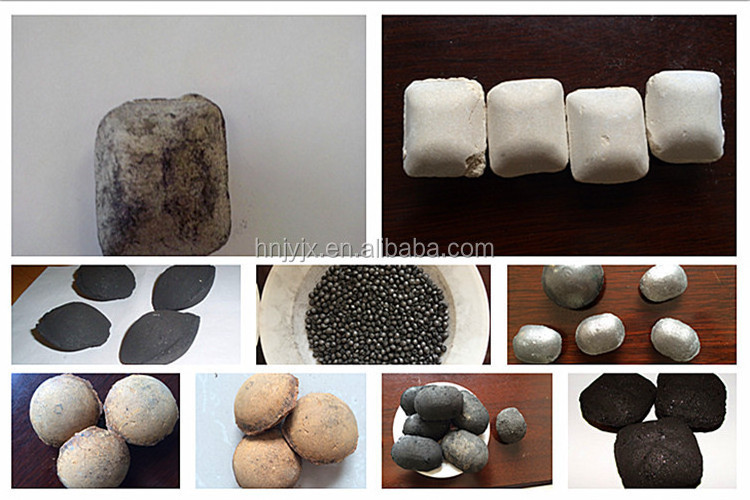

1.Brief introduction of briquette making machine Our good quality briquette making machine is moulded coal equipment which is mainly used to press coal powder,charcoal powder,coke powder,ore powder and other powdery materials into briquettes. These briquettes can be designed into oval shape, egg shape, pillow shape, square shape, round shape, etc.

This machine is widely used in coal industry, minerals industry and metallurgy industry.

Raw material : it can be coal/charcoal, coal charcoal powder,tyre carbon black.

Shapes of Briquettes : There are different shapes, such as round, square, flower shapes and fan-shaped, etc. Or we can manufacture what you require.

2.The applications of the end products

1. Home heating stoves;

2. Hot water boilers and the industrial boilers;

3. Easy transportation for powder materials.

3. W orking principle

1)This series of briquette making machine will pass the powder on to the two pressure roller through the reducer.

2)The two sides and roll rotation, in both the rotating roll, natural materials to enter the ball roll mode, with the roll totation, material pressure on a small become larger.

3)When the material to the two rollers rotating line contact point, the pressure of materials has reached the peak. Tremendous pressure in the role of line, the materials becomes a finished product from the powder ball.

4. Technical parameter of briquette making machine

|

Item Type |

T290 |

T360 |

T400 |

T430 |

T520 |

T650 |

T750 |

T800 |

||

|

Capacity (T/H) |

2 |

4 |

6 |

8 |

10 |

15 |

20 |

25 |

||

|

Roller width (mm) |

200 |

240 |

240 |

240 |

290 |

380 |

430 |

480 |

||

|

Roller Diameter (mm) |

290 |

360 |

400 |

430 |

520 |

650 |

750 |

800 |

||

|

Power (kw) |

5.5 |

7.5 |

11 |

15 |

22 |

37 |

45 |

55 |

||

|

Reducer |

350 |

350 |

400 |

400 |

520 |

750 |

850 |

850 |

||

5. Charcoal briquette making machine production line: