- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v, 380V/50HZ 3Phase(as Customer's Request)

-

Power:

-

7.5kw

-

Dimension(L*W*H):

-

4900*1000*1500mm

-

Weight:

-

6000 kg

-

Product name:

-

roofing sheet roll forming machine

-

Usage:

-

Construction Building Material

-

Shaft material:

-

High Grade No.45 Forged

-

Roller material:

-

GCr15

-

After-sales Service Provided:

-

Online Support

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Control system:

-

PLC(imported Brand)

-

After Warranty Service:

-

Service

Quick Details

-

Production Capacity:

-

700-1200m/h

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

TianYu

-

Voltage:

-

380v, 380V/50HZ 3Phase(as Customer's Request)

-

Power:

-

7.5kw

-

Dimension(L*W*H):

-

4900*1000*1500mm

-

Weight:

-

6000 kg

-

Product name:

-

roofing sheet roll forming machine

-

Usage:

-

Construction Building Material

-

Shaft material:

-

High Grade No.45 Forged

-

Roller material:

-

GCr15

-

After-sales Service Provided:

-

Online Support

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Control system:

-

PLC(imported Brand)

-

After Warranty Service:

-

Service

Traders procurement base

20 years of focus on tile making machinery production

one machine multiple models · can meet your various needs

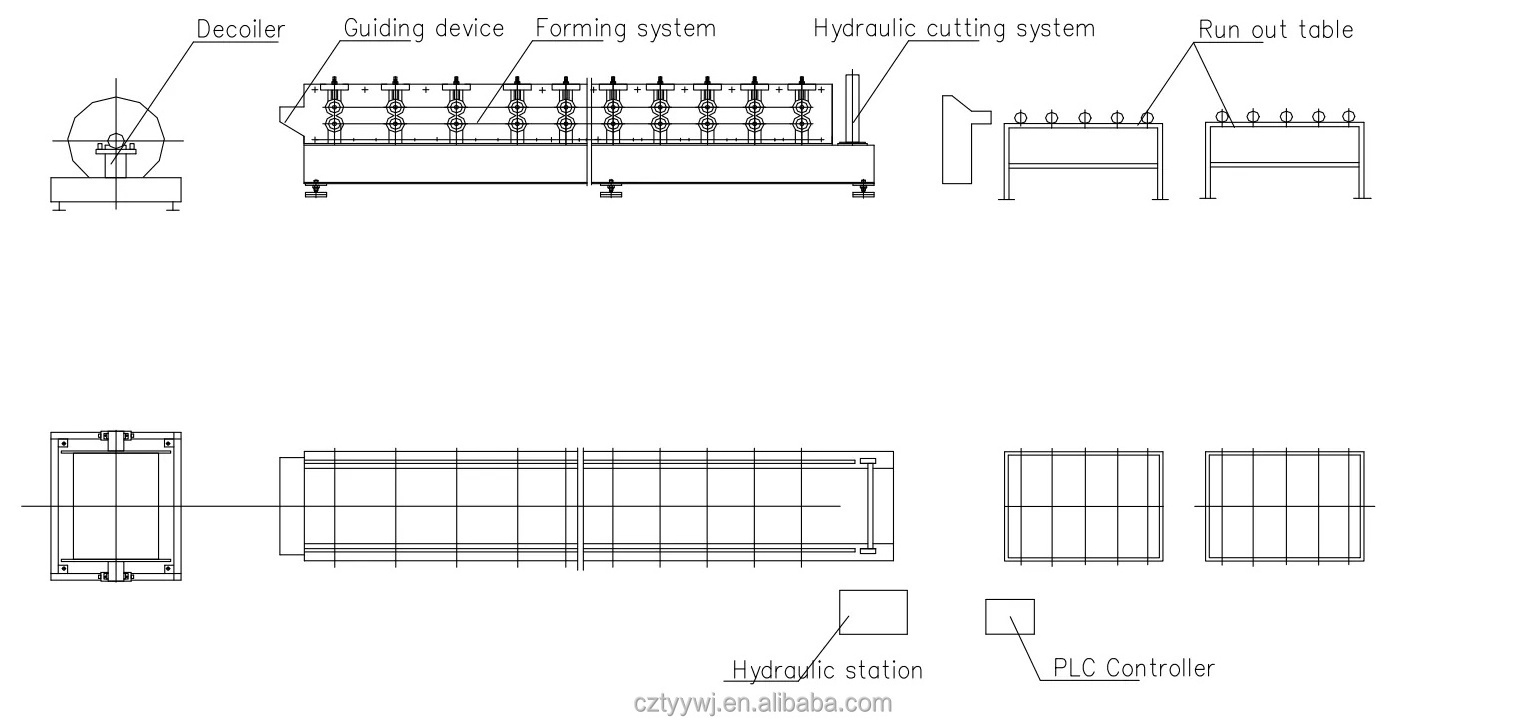

Roll Forming Machine Process

Uncoiling --- Material Feeding --- Roll Forming --- Step Making --- Automatic Cutting --- Products Receiving

Uncoiling --- Material Feeding --- Roll Forming --- Step Making --- Automatic Cutting --- Products Receiving

Machine parameters

|

Tile making machine Setting Parameters

|

|

|

|

1.Weight capacity of decoiler

|

5T

|

|

|

2.Appearance Size(L*W*H)

|

6500*1500*1200

|

|

|

3.Raw material /feeding sheet material

|

colored steel & galvanized steel

|

|

|

4.Roller material

|

45# high grade steel

|

|

|

5.Shaft material

|

45# high grade steel

|

|

|

6.Kind of drive

|

chain drive

|

|

|

7.Cutting system

|

automatic hydyaulic cutting

|

|

|

8.Cutting blade material

|

Cr 12 high grade steel

|

|

|

9.Frame material

|

300 H-high grade steel

|

|

|

10. Control system

|

totally automatic PLC control system

|

|

|

11.Main power

|

3.5 kw

|

|

|

12.Roller stations

|

13 rows

|

|

|

13.Speed of production

|

8-12m/min

|

|

|

14.Thickness of colored steel

|

0.2-0.8mm

|

|

|

15.Frame material

|

300 H-steel

|

|

Customer Photos

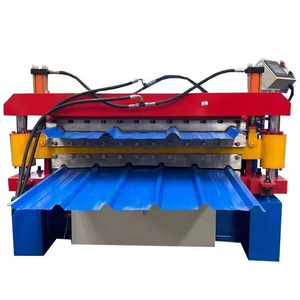

Trapezoidal sheet roll forming machine

Trapezoidal sheet roll forming machine popular sell in many countries,

Coil width before rolling is 1200mm /1220mm / 1250mm.

After rolling product width is 1000mm, Material common is PPGI material, material thickness common between 0.3-0.8 mm. Machine details is like up type:

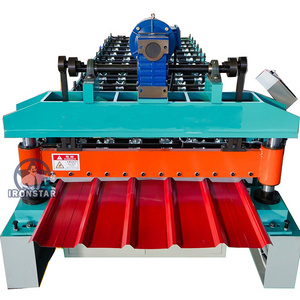

Corrugated roof sheet roll forming machine

Glazed tile roll forming machine

More design and machine videos - consult us

Details Images

Hot Searches