- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

blade shredder plastic recycling of plastic blades and knives

-

Advantage:

-

Super Hardness High Precession

-

Application:

-

Polyurethane Machine

-

Certificate:

-

ISO9001

-

Size:

-

10-1000MM

-

Keywords:

-

plastic shredder blade

-

Appliacation:

-

Plastic recycling machine

-

OEM & ODM:

-

acceptable

Quick Details

-

Place of Origin:

-

China, Shanghai

-

Brand Name:

-

ZHIJING

-

Spare Parts Type:

-

Knives and blades

-

Product name:

-

blade shredder plastic recycling of plastic blades and knives

-

Advantage:

-

Super Hardness High Precession

-

Application:

-

Polyurethane Machine

-

Certificate:

-

ISO9001

-

Size:

-

10-1000MM

-

Keywords:

-

plastic shredder blade

-

Appliacation:

-

Plastic recycling machine

-

OEM & ODM:

-

acceptable

Product Description

Packing & Delivery

1. Introduction of plastic shredder blade price,waste plastic crusher,shredder plastic

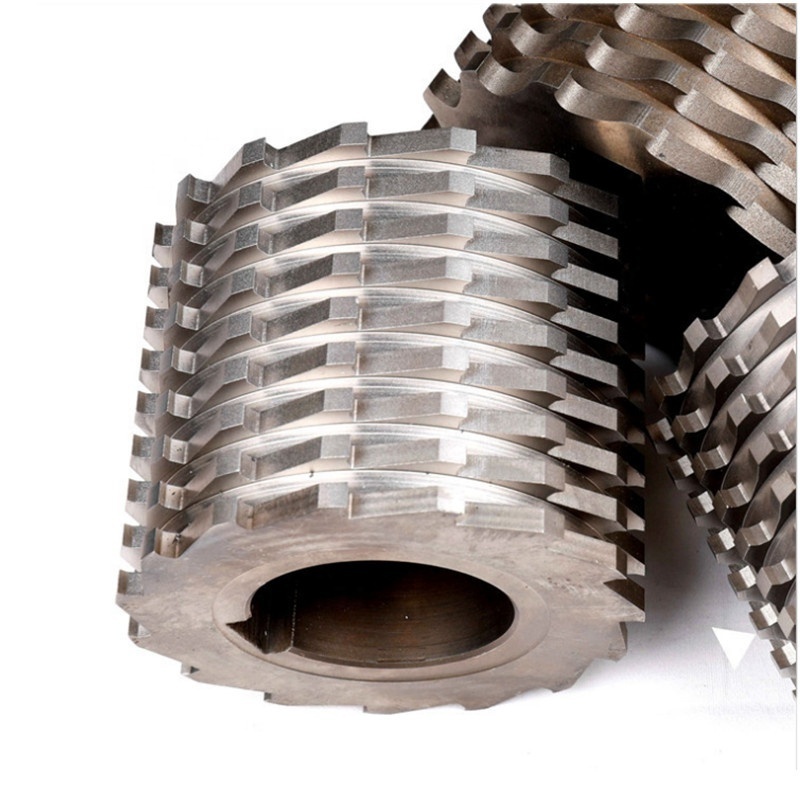

The biaxially shredder shear shredder known by shearing, tearing and pressing the material to achieve reduced size, which is mainly used for packing tape shredder, tires, films, bags, and other plastic waste nets Of the broken recycling.

With dual-axis independent drive, unique knife shaft structure and four-angle rotary tool, in the low-speed high-torque production process, there will be no winding axis, or stuck equipment phenomenon, thereby improving the production efficiency.

2. Features of plastic shredder blade price,waste plastic crusher,shredder plastic

This multifunction shredder can shred and recycling the following materials:

1.A Variety Of Hollow Containers: Plastic Beverage Cans, Plastic Barrels, Drums, Crates, Packaging Barrels.

2.Waste Appliances: TV, Washing Machine, Refrigerator Shell.

3.Pipe: Large Pipe, Pipe Fittings, PE Pipe.

4.The Old Template: Wooden Pallets, Plastic Pallets, Forklift Pallets.

5.Waste Tires: Tires Tires, Truck Tires.

6.Scrap Metal: Car Shell, Aluminum, Scrap Aluminum, Engine Shell, Lead And Thickness Of 5Mm Below The Plate, Food Waste, Garbage, Animal Carcass, Medical Waste, Biological Orange, Garden Garbage.

7.Plastic Head Material, Paper Rope, and Other Materials.

3. Application of hot sale steel shredder machine ,shredder for electric motor recycling prices cost:

1. Plastic: large head material, engineering plastics, paint barrels, glass

2. Appliances: TV sets, monitors, microwave ovens, dishwashers and other small and medium-sized home appliances shell, electrical equipment

3. Electronic products: computer host shell, hard drive, CD-ROM, battery shell

4. Pipe: PVC, PE, PP and other pipe, urban water supply pipe, drain pipe

5. Wood: logs, pallets. Wood chop board, piece of furniture

6. Rubber: waste car tires, conveyor belt

7. Metal: metal sheet such as copper, aluminum or iron, aluminum castings and crush blocks, motorcycles, car engine housings, oil filters

8. Worn clothes and so on.

4 Advantages

1. Unique multiple combination sealing structure effectively blocks the contact of broken material and grease.

2. The liquid material can protect the bearing, gear, ensuring continuous and stable operation of machine.

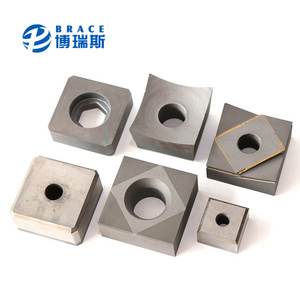

Moving blade:

1. The moving blade material is made of special alloy tool steel forging blanks, precision machining, multiple heat treatments and low temperature freezing heat treatment technology.

2. The overall toughness hardness can be used repeatedly.

Shredding Blade:

1. CNC manufactured to extreme tolerances.

2. 55SiCr, 09CrSi is alloy tool steel with high tool hardness and good wear resistance.

3. Cr12MoV, Cr12Mo1V and SKD-11 are cold-working die steels with similar performance, strong wear resistance and strong impact resistance.

Company Profie

Zhijing blades were 20% sharper out of the box on initial cutting performance than any other manufacturer worldwide – as a user, you can count on cleaner cuts, and cleaner cuts lead to longer blade life.

Zhijing blades lasted 72% longer than the leading USA manufacturer of machine blades in total cost per cut – your best value is and remains Zhijing blades, dollar for dollar.

Across all categories of testing, you will get better value for your cutting operations with Zhijing blades. In today’s highly competitive market, you know it is not always the “price per blade” that determines value, but the quality of cuts you get as well as the number of cuts you get. Total value can far outweigh initial price and you get the best total value with Zhijing.

FAQ

1.Excellent quality and reasonable price

We have high quality high-tech products both in China and abroad of machinery parts and the we are willing to compare, the price

is very good! In the same industry, we control the materials quality before manufacturing, and control products quality during

manufacturing, also examination the products before packaging, that ensures our products’ excellent quality.

2.Best Service

Company sticks to a "Human Oriented" management pattern and attaches importance to the selection and cultivation of qualified

employees. Every year, periodic or aperiodic professional trainings held at home and abroad make sure the employees have grasped

the latest technology and skills. Outstanding expertise and employee quality guarantees high-quality products.What's more, good

after-sale services and technical support eradicate your fear of trouble in the future when purchasing or using our products.

For maximum availability of professional service, we are now available 24 hours a day 7 days a week. Your call will be returned by

one of our expert service staff in the order it is received. In some instances you problem or concern may be resolved over the

phone.

3. Training

Each Year, ZJ offers classroom and on-site training courses. This will help to save much dollars in capital and operating costs .

Reduce manufacturing costs by designing for manufacture and manufacturing for better quality products.

We have high quality high-tech products both in China and abroad of machinery parts and the we are willing to compare, the price

is very good! In the same industry, we control the materials quality before manufacturing, and control products quality during

manufacturing, also examination the products before packaging, that ensures our products’ excellent quality.

2.Best Service

Company sticks to a "Human Oriented" management pattern and attaches importance to the selection and cultivation of qualified

employees. Every year, periodic or aperiodic professional trainings held at home and abroad make sure the employees have grasped

the latest technology and skills. Outstanding expertise and employee quality guarantees high-quality products.What's more, good

after-sale services and technical support eradicate your fear of trouble in the future when purchasing or using our products.

For maximum availability of professional service, we are now available 24 hours a day 7 days a week. Your call will be returned by

one of our expert service staff in the order it is received. In some instances you problem or concern may be resolved over the

phone.

3. Training

Each Year, ZJ offers classroom and on-site training courses. This will help to save much dollars in capital and operating costs .

Reduce manufacturing costs by designing for manufacture and manufacturing for better quality products.

Recommend Products

Contact us

Hot Searches