- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

Different model

-

Weight:

-

3800 KG

-

Product name:

-

Dewatering Vibrating Screen

-

Company name:

-

Weifang Guote Mining Equipment Co., Ltd

-

Material:

-

Carbon Steel/ Stainless Steel 304

-

Motor:

-

Vertical Vibrating Motor

-

Function:

-

Screening\separation\sorting\sieving

-

Layer(s):

-

1-5 Layers

-

Capacity:

-

10-100t/h

-

Mesh size:

-

0.1-0.5mm

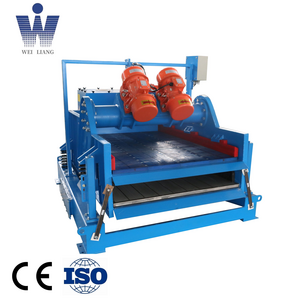

Quick Details

-

Type:

-

Circular

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GUOTE

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

Different model

-

Weight:

-

3800 KG

-

Product name:

-

Dewatering Vibrating Screen

-

Company name:

-

Weifang Guote Mining Equipment Co., Ltd

-

Material:

-

Carbon Steel/ Stainless Steel 304

-

Motor:

-

Vertical Vibrating Motor

-

Function:

-

Screening\separation\sorting\sieving

-

Layer(s):

-

1-5 Layers

-

Capacity:

-

10-100t/h

-

Mesh size:

-

0.1-0.5mm

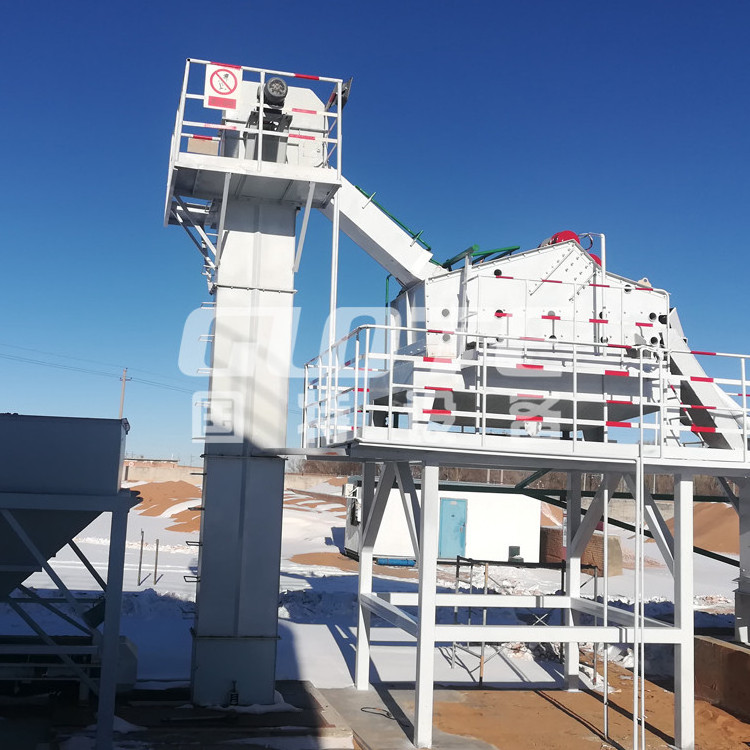

vibrating dewatering screen

Production Introduction:

The linear dewatering screen is a large-scale screening equipment with international quality developed by our company in recent years. It is suitable for the dewatering of raw coal in coal preparation plants, classification, desliming, screening of mines, power plant screening and coal chemical industry and other new energy industry material separation process. .

Linear motion mode. The material is not easy to block the sieve hole. The sieve plate life is longer than the traditional round vibrating sieve. It is the first choice for the traditional round vibrating screen upgrade.

Advantages:dewatering vibrating screen

1. Adopt self-synchronized technology of waterproof and frequency-specific motor and dual-motor drive to achieve effective dewatering effect

2. The new dry row dehydration process has less investment compared to the traditional process, simple process, small area, etc. It is convenient for system process layout.

3. Professional frequency, amplitude and low power consumption design can suit a variety of dewatering needs, 24 hours continuous dry row operation, V-type screen surface design, -5' climbing surface dewatering, dry exhaust tailings low in water content, high efficiency, large capacity per unit area,

4. Long life of wear-resistant sieve plate. Chess assembling design, convenient replacement, cost saving, sieve size can be selected according to requirements

5. The method of riveting and welding of steel components constitutes a frame body with no internal stress, high strength, light weight and durability.

Technical parameter:

| Model | Screen bevel(℃) | Feed capacity(tph) | Weight(t) |

| GTTS 1036 | -5~-3 | 10-35 | 3.8 |

| GTTS 1236 | -5~-3 | 18-65 | 4.5 |

| GTTS 1536 | -5~-3 | 30-90 | 5.7 |

| GTTS 1838 | -5~-3 | 40-120 | 6.6 |

| GTTS 2138 | -3~0 | 60-150 | 8.2 |

| GTTS 2538 | -3~0 | 80-200 | 11 |