Tool Magazine

- Modularized components enable simpler and more consistent assembly and maintenance operations.

- Patent knife cover, the knife cover of this series can reduce 80% of the adherence of dust and fine chips.

- Standardized wiring, employing connector-type inductive switches, makes maintenance more convenient.

- Fully waterproof knife arm design, coupled with a detached type knife holder, is convenient for the rapid interchange of different knife rod specifications.

- The entire series utilizes ball roller cam boxes, ensuring smooth and stable tool changing.

- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Y) (mm):

-

500

-

Dimension(L*W*H):

-

2700x2700x2700mm

-

Weight (T):

-

5.3 T

-

Range of Spindle Speed(r.p.m):

-

10000 - 12000 r.p.m

-

Spindle Motor Power(kW):

-

11

-

Max. Table Load(kg):

-

1000 kg

-

Feed Speed(mm/min):

-

20000 - 25000 mm/min

-

Rapid Feed Speed(m/min):

-

48

-

Place of Origin:

-

Guangdong, China

-

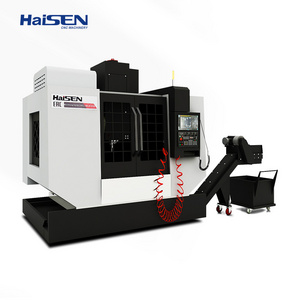

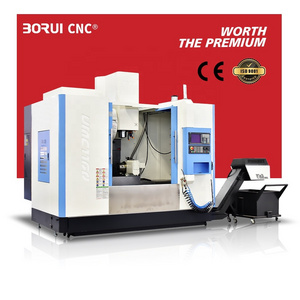

Brand Name:

-

Chansin

-

Voltage:

-

380v/415v

-

Applicable Industries:

-

Metal machining plant, Hardware processing plant, Aluminium processing plant, Iron processing plant, Copper machining plant, Aluminium alloy machining, Zinc alloy machining, Mould machining, Stainless steel machining

-

Marketing Type:

-

Hot Product 2022

-

Core Components:

-

Other

-

Machine Name:

-

CX-850 CNC machine Center

-

machine body:

-

Iron casting HQ300

-

spindle type:

-

BT40

-

Tool magazine type:

-

Arm BT40 - 24- capacity

-

Main spindle power:

-

11KW

-

X,Y,Z axis:

-

X,Y , Z are Linear guide rail

-

X,Y,Z axis rail movement speed:

-

48M/min

-

Spindle speed:

-

12000 rpm

-

Spindle cooling:

-

oil automatic cooling

Quick Details

-

Table Size (mm):

-

1000x500

-

Number of Axes:

-

3

-

Table Travel (X) (mm):

-

1000

-

Table Travel (Y) (mm):

-

500

-

Dimension(L*W*H):

-

2700x2700x2700mm

-

Weight (T):

-

5.3 T

-

Range of Spindle Speed(r.p.m):

-

10000 - 12000 r.p.m

-

Spindle Motor Power(kW):

-

11

-

Max. Table Load(kg):

-

1000 kg

-

Feed Speed(mm/min):

-

20000 - 25000 mm/min

-

Rapid Feed Speed(m/min):

-

48

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Chansin

-

Voltage:

-

380v/415v

-

Applicable Industries:

-

Metal machining plant, Hardware processing plant, Aluminium processing plant, Iron processing plant, Copper machining plant, Aluminium alloy machining, Zinc alloy machining, Mould machining, Stainless steel machining

-

Marketing Type:

-

Hot Product 2022

-

Core Components:

-

Other

-

Machine Name:

-

CX-850 CNC machine Center

-

machine body:

-

Iron casting HQ300

-

spindle type:

-

BT40

-

Tool magazine type:

-

Arm BT40 - 24- capacity

-

Main spindle power:

-

11KW

-

X,Y,Z axis:

-

X,Y , Z are Linear guide rail

-

X,Y,Z axis rail movement speed:

-

48M/min

-

Spindle speed:

-

12000 rpm

-

Spindle cooling:

-

oil automatic cooling

Product Description

PRODUCT DETAILS INSTRUCTION

|

CX - 850

|

|

|

|

System

|

Mitsubishi

|

|

|

X,Y,Z axis type

|

X,Y,Z Linear guide rail

|

|

|

Tool Magazine Capacity

|

Automatic Tool Changer

Tool Number:24 |

|

|

X,Y,Z axis Lubrication System

|

Oil cooling Automatic

|

|

|

Spindle Cooling System

|

Oil cooling Automatic

|

|

|

X/Y/Z-axis Travel

|

800mm/500mm/500mm

|

|

|

Distance from Spindle Nose to Table

|

120mm-660mm

|

|

|

Distance Spindle Center to Column Guide Rail

|

570mm

|

|

|

Working Table Size

|

1000*500mm

|

|

|

Table Max Load

|

1000kg

|

|

|

T Slot

|

4*18T

|

|

|

Spindle Rotation Speed

|

12000rpm

|

|

|

Spindle Motor Power

|

11kw

|

|

|

X/Y/Z-axis Motor Power

|

3.0/3.0/3.0kw

|

|

|

Rapid Traverse(X/Y/Z-axis)

|

48000/48000/48000mm/min

|

|

|

Cutting Speed

|

0-20000mm/min

|

|

|

Spinldle Taper

|

BT40

|

|

|

Positioning Accuracy

|

±0.005mm/500mm

|

|

|

Repeat Positioning Accuracy

|

±0.003mm/500mm

|

|

|

Machine Size

|

2700mm*2700mm*2700mm

|

|

|

Machine Weight

|

5.3ton

|

|

|

Warranty

|

One Year

|

|

|

Main Component Brand

|

|

|

|

Spindle

|

spinder/Royal/Waylong/TD in Taiwan

|

|

|

Tool Magazine

|

Okada/Sanjet/Deta in Taiwan

|

|

|

Bearing

|

NSK in Japan or FAG in Germany

|

|

|

Lead screw/Guide Rail

|

Hiwin/PMI in Taiwan

|

|

|

Machine body

|

Chansin iron casting HQ300

|

|

|

Metal plate

|

Chansin brand

|

|

Taiwan brand guide rail and lead screw : HIWIN / PMI

Taiwan brand line rails ensure machining accuracy, long service life of the machine tool, Hiwin screw rod, high-speed feed, high operating efficiency, low heat generation, and high-speed feed.

The X, Y, and Z direction guide rails and lead screws are all sealed and protected, effectively ensuring the cleanliness of the lead screws and guide rails, and ensuring the transmission and motion accuracy of the machine tool.

Bearings : FAG / NSK

- High stability

- Stronger rigidity

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

Taiwan Brand Spindle :

POSA/WLT/VOLIS/ROYAL optional

Belt drive or direct drive optional

Coolant through spindle optional

High Spindle speed

: 8000rpm/10000rpm/12000rpm

High Precision

: High Precision Angular Contact Thrust Ball Bearings

High Rigidity

: Strong axial and radial bearing capacity

The spindle adopts a central blowing structure, and the inner cone of the spindle is cleaned with central high-pressure gas quickly after the spindle releases the tool to ensure the accuracy of tool clamping.

-------------------------------------------------------------------------------------------------------------------

CNC Control Systems Optional

- Japan Mitsubishi M80 - Japan Fanuc 0i-MF

- Germany Siemens 828D - Taiwan Syntec 22MA

It conforms to the ergonomic interactive interface and cooperates with the servo drive to complete the high-precision milling processing requirements.

-------------------------------------------------------------------------------------------------------------------

Oil Lubrication System

- Brand automatic lubricating device is used to perform forced lubrication on each sliding surface and ball screw.

- The time interval of oil injection and the amount of oil injection can be adjusted.

- When the oil level is too low (lack of oil), the machine will display an alarm.

- The lubricating oil is T68# guideway lubricating oil.

- The volume of the lubricating box is 2 liters.

- Lubrication motor power 150W, system maximum pressure 5KG/CM2.

The whole machine covers the lubrication system, equipped with pure copper large-diameter oil pipes to work.

- The components of the machine tool such as the table, column, and guide rail are equipped with oil separators, and the timing and quantitative automatic intermittent lubrication can efficiently lubricate every detail, and the work is continuous and stable.

Quenching treatment workbench

It can improve the strength, hardness and wear resistance of the workpiece and prolong the service life. The vertical machining center with quenched workbench and guide rail is more stable in terms of high rigidity, high precision and hardness.

Thick stainless steel inner protection

The internal defense is made of 304 stainless steel. The outer sheet metal is 2 mm thicker, and the safety is higher with GFRP glass. The cast inner protective bracket is not easy to deform and is more firm in use.

Rotary Table

Brand: Taiwan TJR

Min. indexing angle –0.001°

Quality Control

Vertically Test

Spindle Coupling Inspection

Laser Test

Hand Scaping

Circular Test

Parallelism Test

Machined Sample

Hot Searches