- Product Details

- {{item.text}}

Quick Details

-

Capacity:

-

100-3000TPD

-

Energy-saving:

-

30%

-

Fuel:

-

coal/gas/oil

-

Mode of trade:

-

EXW/FOB/CFR/CIF

-

Spare parts:

-

provided

-

After sale service:

-

for the whole using life

-

Market:

-

Africa, Europe, Asia,etc

-

Material:

-

Q235

-

Certification:

-

ISO CE BV SGS

Quick Details

-

Place of Origin:

-

Henan, China

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Product name:

-

Copper Iron ore and Gold Mining Concentrate Processing Plant

-

Capacity:

-

100-3000TPD

-

Energy-saving:

-

30%

-

Fuel:

-

coal/gas/oil

-

Mode of trade:

-

EXW/FOB/CFR/CIF

-

Spare parts:

-

provided

-

After sale service:

-

for the whole using life

-

Market:

-

Africa, Europe, Asia,etc

-

Material:

-

Q235

-

Certification:

-

ISO CE BV SGS

Copper Iron ore and Gold Mining Concentrate Processing Plant

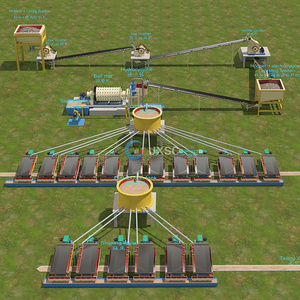

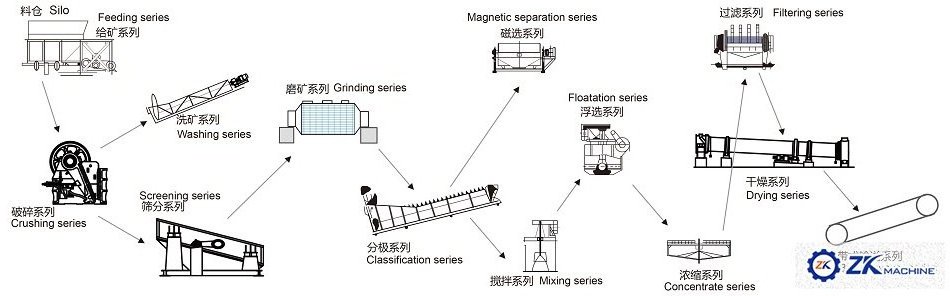

Overview of Flotation Processing Plant

| Flotation Processing Plant | |

| Overview | Copper Ore beneficiation line is mainly composed of jaw crusher, ball mill, spiral classifier, magnetic separator, flotation machine, ore concentrator and dryer machine combining with ore feeder, bucket elevator and belt conveyor which formed a complete ore beneficiation production line. |

| Advantage |

1.Low noise in construction site, high air quality.

2.High crushing efficiency with excellent production performance. 3.Our components are all purchasing from famous brands, with good wear resistance. |

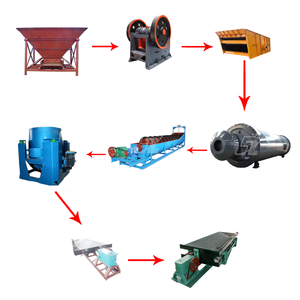

Raw material ores is exploited from mountain are big size,so it is necessary to crush firstly,in this process,the raw materials will be feed into primary crusher by feeder,then come into secondary crusher.The materials will go into screen after first and secondry crusher, the

suitable size material (≤25mm)

will go to next step. Oversize (>25mm) material will go back to secondary crusher to crush again. This forms a closed crush circuit.

In this process, material will be grinded into suitable sizes (about

200 mesh

) for beneficiation. After grinding material will come to classifier. In classifier, suitable size material will go to next step. Coarse material will go back to ball mill for grind again. This process is a closed grind circuit.

In this process, materials will be separated by flotation, magnetic separator or gravity concentrating machine. We will get the materials that we need.

After beneficiation, there are some residual water in ore concentration. So we have to carry on concentrate dehydration to meet the requirements of transportation and smelting.

500 TPD Ore Processing Line Equipment List for Your Reference

|

Equipment |

Size |

QTY (set) |

Power (kW) |

Remarks |

|

Chute feeder |

980×1240 |

1 |

7.5 |

|

|

Jaw crusher |

PE400×600 |

1 |

30 |

Cast steel rack |

|

Jaw crusher |

PEX250×1000 |

2 |

37 |

Cast steel rack |

|

Swaying feeder |

600×600 |

1 |

2.2 |

|

|

Rotary ball mill |

GM2.1×4.0 |

1 |

245 |

|

|

Spiral classifier |

FLG-2000 |

1 |

18.5 |

|

|

Magnetic separator |

CTB900×1800 |

1 |

4 |

2500gs |

|

Magnetic separator |

CTB750×1800 |

2 |

3 |

1400~180gs |

|

Equipment |

Size |

QTY (set) |

Power (kW) |

Remarks |

|

Chute feeder |

980×1240 |

1 |

7.5 |

|

|

Jaw crusher |

PE600×900 |

1 |

75 |

Cast steel rack |

|

Fine jaw crusher |

PEX250×1200 |

2 |

37 |

Cast steel rack |

|

Vibrating feeder |

DZ-5 |

2 |

0.75×2/set |

|

|

Ball mill |

GM2.7×3.6 |

1 |

475 |

|

|

Spiral classifier |

FLG-3000 |

1 |

30 |

|

|

Magnetic separator |

CTB-1024 |

1 |

5.5 |

2500gs |

|

Magnetic separator |

CTB-1021 |

2 |

4/set |

1400~1800gs |

Ball Mill

Jaw Crusher

Magnetic Separator

Henan Zhengzhou Mining Machinery Co., Ltd (ZK) was found in 1956 . After half century development, it becomes a comprehensive modernized enterprise, including the business service such as scientific research, design, develop, manufacture, sales, installation, test and training.

We are China Top 5 Mining Equipment Manufacturer

Our Customer are From More Than 130 Countries

Our Engineers Provide Technical Support On Customer Site

We have got

ISO9001:2008 Quality Management System Certification

CE Certification (Ball Mill)

ISO14001:2004 Environmental Management System Certification

OHSAS 18001:2007 Occupational Health&safety Management System Certification

Get solution design and price list for you project,Send Inquiry now !

↓↓↓