2. Put the

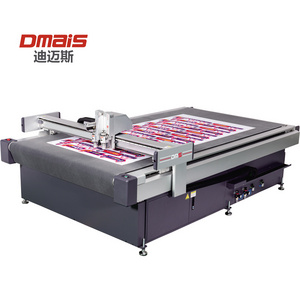

leather car mat fabric

on the work surface, start the vacuum adsorption function and the camera recognition system.

3. Enter the identified material outlines and defects into the database, and start the typesetting function.

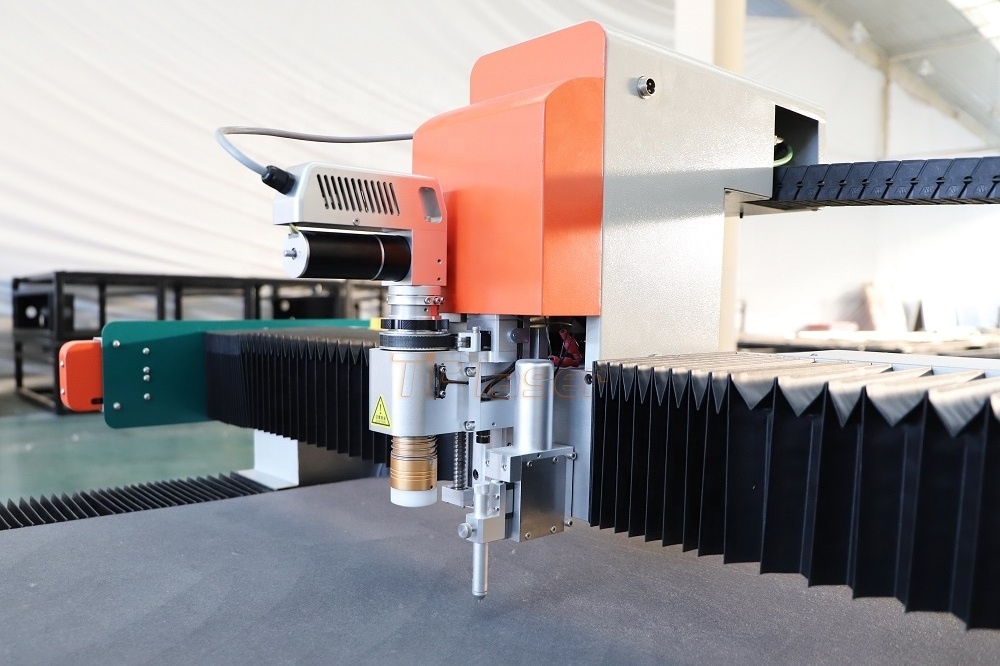

4. The machine automatically typeset, and then starts automatic cutting, punching, marking and blanking functions.

4. The machine automatically typeset, and then starts automatic cutting, punching, marking and blanking functions.

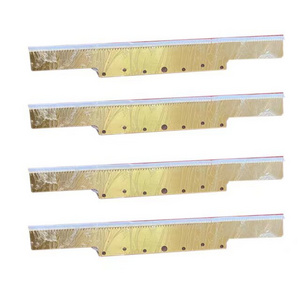

5.We have multi-function tool, Vibrating knife full cut, semi-cutting cut, indentation, drawing mark, cursor positioning, camera positioning edge cutting, high power active round knife etc.

6.Safety devices use infrared sensing, safe and reliable.