- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

240kg

-

Size:

-

3310* 1050*1900mm(external size)

-

Power:

-

0.75

-

Weight (KG):

-

900 kg

-

Product name:

-

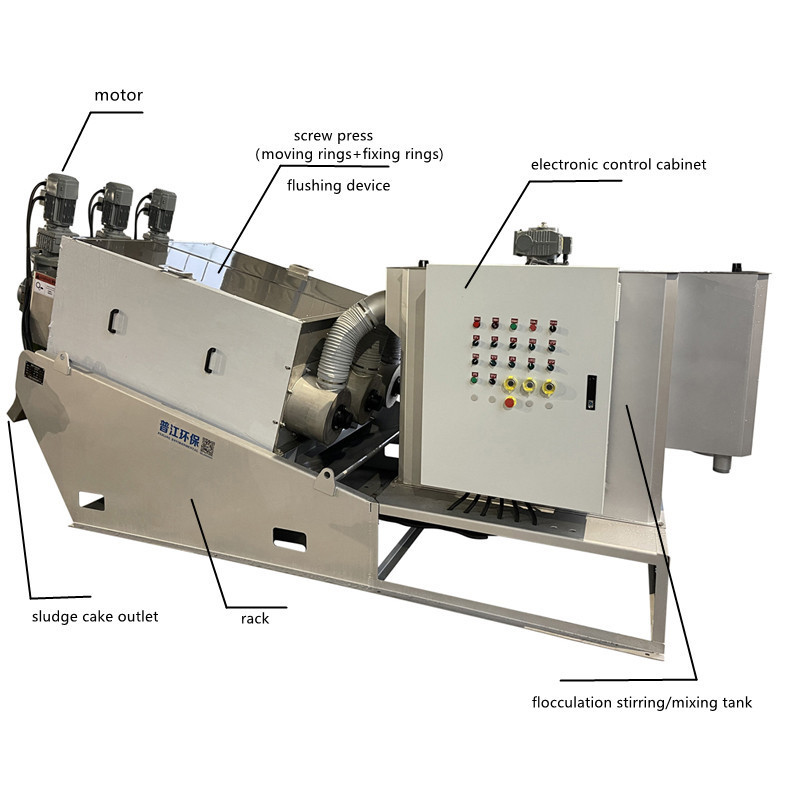

screw press sludge dewatering machine

-

Type:

-

screw

-

certificate:

-

ISO9001,BV certificate

-

Electrical components:

-

Schneider, Omron

-

Motor:

-

Siemens,SEW,chinese brand motor,or others

-

Operation:

-

Automatic

-

Application:

-

sewage treatment

-

Raw material:

-

SS304 or SS316

-

outlet slduge cake moisture content:

-

75%-85%

-

after-sale service:

-

technology assistance

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

PJEP

-

Material:

-

wodden box

-

Weight:

-

240kg

-

Size:

-

3310* 1050*1900mm(external size)

-

Power:

-

0.75

-

Weight (KG):

-

900 kg

-

Product name:

-

screw press sludge dewatering machine

-

Type:

-

screw

-

certificate:

-

ISO9001,BV certificate

-

Electrical components:

-

Schneider, Omron

-

Motor:

-

Siemens,SEW,chinese brand motor,or others

-

Operation:

-

Automatic

-

Application:

-

sewage treatment

-

Raw material:

-

SS304 or SS316

-

outlet slduge cake moisture content:

-

75%-85%

-

after-sale service:

-

technology assistance

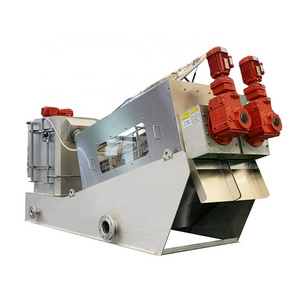

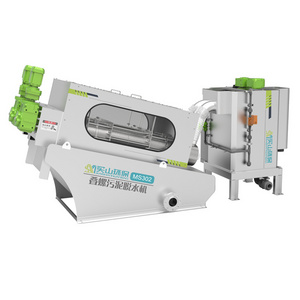

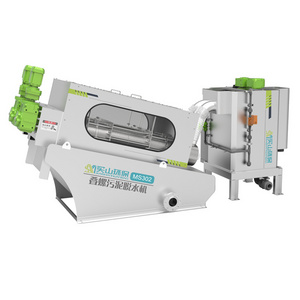

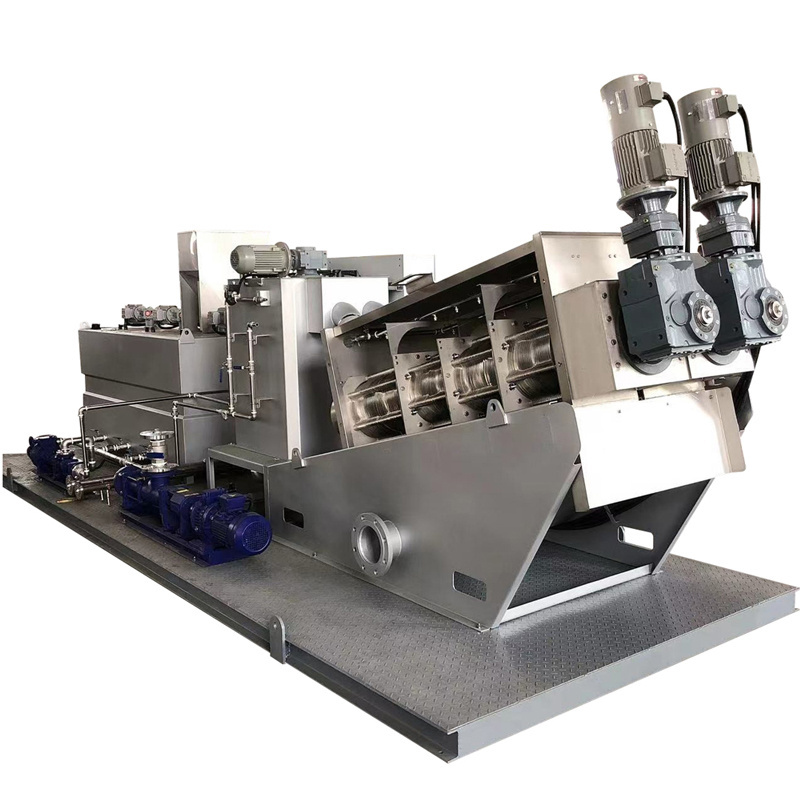

Product Pictures

When the machine starts running,the sludge is pumped into the screw press from the feed inlet port ,then enters into the flocculation mixing tank,and then gradually goes through screw shaft main body,and at last discharged from the sludge cake outlet port.Because the gaps between the screw shaft blades will gradually getting narrower,the sludge is bearing heavier pressure.Then the water is gradually dehydrated.Relying on the self-cleaning function of the fixed plates and the moving plates,block issue can be well avoided .

Details Images

Our Advantages

1.Low operation cost:below 40% of belt press.

2.Power-saving:less than 5% of centrifuge.

3.Water-saving:less than 0.1% of belt filter press.

4.Saving-drugs:saving around 60%.

5.Compact:saving more than 60% of the investment for dehy-dration room.

6.Non-clogging:processing the facts & oils and fiber sludge perfectly.

2.Power-saving:less than 5% of centrifuge.

3.Water-saving:less than 0.1% of belt filter press.

4.Saving-drugs:saving around 60%.

5.Compact:saving more than 60% of the investment for dehy-dration room.

6.Non-clogging:processing the facts & oils and fiber sludge perfectly.

Produc Attribute

|

Model Number

|

DS handling capacity (KG/H)

10000mg/L≤ss≤20000mg/L

|

External Dimension L(mm)×W(mm)×H(mm)

|

Net Weight(kg)

|

Operation Weight(kg)

|

|

|

|

|

|

|

|

PJXDL131

|

7-14

|

1870× 730× 1065

|

250

|

395

|

|

PJXDL132

|

14-28

|

2000× 960× 1070

|

420

|

540

|

|

PJXDL251

|

15-30

|

2690× 880× 1500

|

550

|

660

|

|

PJXDL252

|

30-60

|

2810× 1120× 1500

|

550

|

660

|

|

PJXDL301

|

35-70

|

3310× 1000×1700

|

900

|

1300

|

|

PJXDL302

|

70-140

|

3460× 1270×1700

|

1350

|

2000

|

|

PJXDL303

|

105-210

|

3630× 1620× 1700

|

1900

|

2700

|

|

PJXDL304

|

140-280

|

3960× 2040× 1750

|

2500

|

3600

|

|

PJXDL351

|

60-120

|

3610× 1100× 1850

|

1100

|

2000

|

|

PJXDL352

|

120-240

|

3820×1410×1850

|

2100

|

3250

|

|

PJXDL353

|

180-360

|

4120×1770×1850

|

3100

|

4600

|

|

PJXDL354

|

240-480

|

4320× 2290× 1850

|

4100

|

5700

|

|

PJXDL401

|

80-160

|

4550×1160×2250

|

2200

|

4200

|

|

PJXDL402

|

160-320

|

4870×1680×2250

|

3500

|

6000

|

|

PJXDL403

|

240-480

|

4790×2550×2250

|

5500

|

8000

|

|

PJXDL404

|

320-640

|

4840×3120×2250

|

7000

|

9500

|

Production and application

Flow Chart

Hot Searches