- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

BEDO

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2.5*1.5*2M

-

Motor Power (Kw):

-

customized

-

Power (kW):

-

110

-

Weight (KG):

-

5800 KG

-

Marketing Type:

-

New Product 2024

-

Name:

-

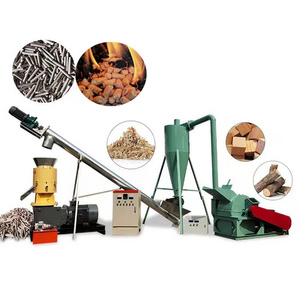

biomass wood pellet machine vertical ring die pellet mill

-

Application:

-

making wood pellets

-

Usage:

-

for biomass fuel

-

Raw material:

-

Rice Husk,straw,wood waste

-

Final product:

-

wood pellets

-

Motor:

-

customized

-

Advantage:

-

Environmentally Friendly

-

Packing:

-

wooden case

-

Driven by:

-

motor or engine

Quick Details

-

Pellet Diameter (mm):

-

6 - 10

-

Output (kg/h):

-

500 - 4000 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BEDO

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2.5*1.5*2M

-

Motor Power (Kw):

-

customized

-

Power (kW):

-

110

-

Weight (KG):

-

5800 KG

-

Marketing Type:

-

New Product 2024

-

Name:

-

biomass wood pellet machine vertical ring die pellet mill

-

Application:

-

making wood pellets

-

Usage:

-

for biomass fuel

-

Raw material:

-

Rice Husk,straw,wood waste

-

Final product:

-

wood pellets

-

Motor:

-

customized

-

Advantage:

-

Environmentally Friendly

-

Packing:

-

wooden case

-

Driven by:

-

motor or engine

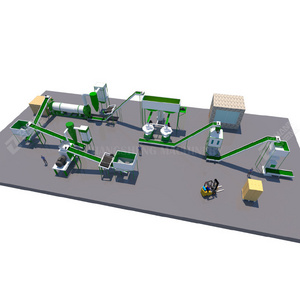

High Quality Alfalfa Wood Pellet Production Line Hay Straw Pellet Making Machine

We make flat die and ring die pellet machines,T

he capacity ranges from 200kg/h to 30t/h.

The whole wood pellets production line started from wood chipper, crusher, sawdust dryer, the pellet machine, the cooler and the packing machine, they are connected by some conveyors.

It is capable of recycling all kinds of waste wood, rice husks, construction lumber, etc.

Product Description

Specification

Ring die wood pellet machine is suitable for wheat straw, corn straw, peanut seedlings, cotton straw, tobacco straw and other crop straw and various wood chips, bark, sawdust and other raw materials, stable output, simple operation. The machine adopts gear transmission, the spline shaft is linked to the drive shaft, and then the drive shaft drives the inner surface of the press wheel mold to complete the pressing process. This process material by high pressure, high temperature effect, produce physical changes or appropriate chemical changes (according to the material), make powder material to form a lengthening cylindrical solid body, the cylindrical solid body continues to extend until the uniform distribution of the mold around the cutter cut, the formation of a certain specification of pellets.

|

Model

|

Power

|

Capacity

|

|

BD-KL470

|

55kw

|

0.8-1.0t/h

|

|

BD-KL560

|

90kw

|

1.2-1.5t/h

|

|

BD-KL600

|

132kw

|

1.8-2.0t/h

|

|

BD-KL700

|

160kw

|

2.0-3.0t/h

|

|

BD-KL850

|

220kw

|

2.5-3.5t/h

|

Features & Advantages

Features:

1.The hard surface helical gear deceleration, tooth surface widened, modulus increased, meshing degree, load bearing capacity enhanced, is the conventional reducer life 3-5 times.

2.Reducer gear adopt German NLES gear grinding machine, smooth transmission, low noise, long life, can withstand high power and heavy load.

3.Spindle shorten, bear torque.

4.Reducer lubricating oil adopts independent water cooling system device, reduce oil temperature, increase the service life of internal bearing.

5.Spindle bearing, the reducer itself rare lubrication, that is, to achieve lubrication effect and reduce the temperature of

spindle bearing.

6.Roller bearing, using independent automatic oiling system, timing oiling, good stability, prolong service life.

1.The hard surface helical gear deceleration, tooth surface widened, modulus increased, meshing degree, load bearing capacity enhanced, is the conventional reducer life 3-5 times.

2.Reducer gear adopt German NLES gear grinding machine, smooth transmission, low noise, long life, can withstand high power and heavy load.

3.Spindle shorten, bear torque.

4.Reducer lubricating oil adopts independent water cooling system device, reduce oil temperature, increase the service life of internal bearing.

5.Spindle bearing, the reducer itself rare lubrication, that is, to achieve lubrication effect and reduce the temperature of

spindle bearing.

6.Roller bearing, using independent automatic oiling system, timing oiling, good stability, prolong service life.

Advantages:

1.Vertical feeding

Vertical feeding, direct in place, static mold, rotary press wheel, material centrifugal, evenly distributed around.

2.Circular mold

Double-layer annular mold, vertical structure, the use of pelleting chamber cooling cooling dual-use, more choices, more harvest;

3.Independent discharging device

Independent discharging device, ensure the forming rate of particles, reasonable design, low consumption and high energy. 24 hours work, automatic lubrication.

4.Environmental protection and energy saving

The main force element adopts high alloy wear-resisting material, the life of wearing parts is twice that of similar products. Sawdust straw pellet machine is a special equipment for processing sawdust straw fuel particles, low noise, low fault, low energy consumption, continuous production of non-stuck machine.

1.Vertical feeding

Vertical feeding, direct in place, static mold, rotary press wheel, material centrifugal, evenly distributed around.

2.Circular mold

Double-layer annular mold, vertical structure, the use of pelleting chamber cooling cooling dual-use, more choices, more harvest;

3.Independent discharging device

Independent discharging device, ensure the forming rate of particles, reasonable design, low consumption and high energy. 24 hours work, automatic lubrication.

4.Environmental protection and energy saving

The main force element adopts high alloy wear-resisting material, the life of wearing parts is twice that of similar products. Sawdust straw pellet machine is a special equipment for processing sawdust straw fuel particles, low noise, low fault, low energy consumption, continuous production of non-stuck machine.

Final Production

Hot Searches