- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

210*150*125 cm

-

Weight:

-

460 kg, 460 kg

-

Product name:

-

floating feed processing machines

-

Application:

-

Make Animal Feed

-

Usage:

-

Fish Feed Extruder Mill

-

Motor Power:

-

22 kw

-

Feed motor power:

-

0.4 kw

-

Capacity:

-

300 KG/H

-

Pellet size:

-

0.8 mm-12 mm

-

Packing:

-

Wooden Case Packaging

Quick Details

-

Max. Capacity:

-

300KG/H

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380V/50Hz, 380V/50Hz

-

Dimension(L*W*H):

-

210*150*125 cm

-

Weight:

-

460 kg, 460 kg

-

Product name:

-

floating feed processing machines

-

Application:

-

Make Animal Feed

-

Usage:

-

Fish Feed Extruder Mill

-

Motor Power:

-

22 kw

-

Feed motor power:

-

0.4 kw

-

Capacity:

-

300 KG/H

-

Pellet size:

-

0.8 mm-12 mm

-

Packing:

-

Wooden Case Packaging

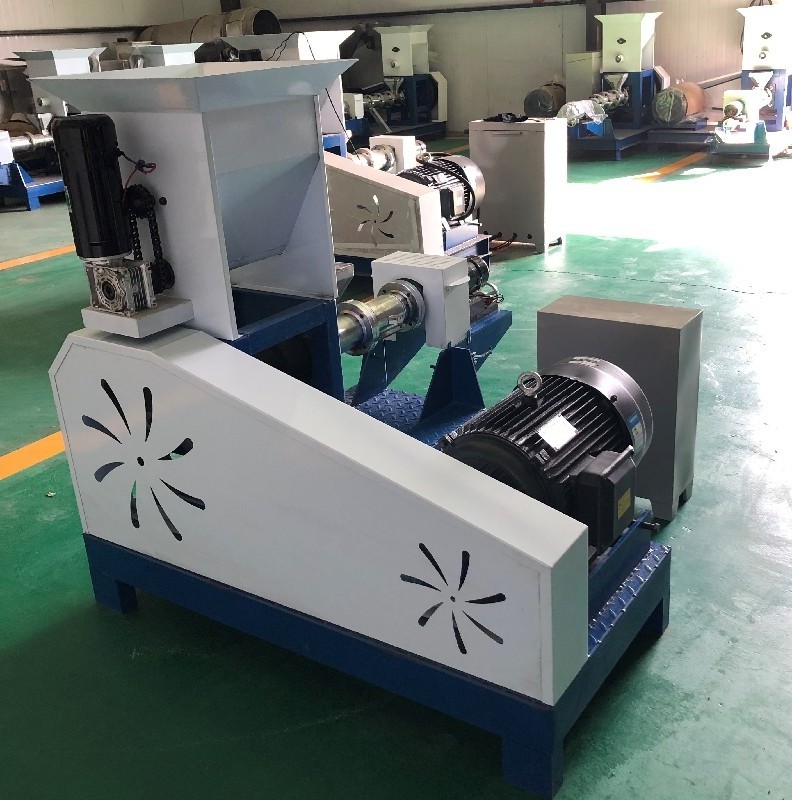

Floating feed pellet machine/feed puffing machine

Floating feed pellet machine is multi-purpose, widely used in feed factories, aquaculture, pet breeding, etc. Suitable for making a variety of feeds: floating fish feed, loach and frog feed, shrimp and crab feed, dog food, cat food, bird food, tortoise food and other floating extruded particles. It can also produce extruded raw materials, extruded corn, extruded soybeans, etc.

It can produce a variety of patterns, and customize molds according to requirements, each machine is equipped with

6 molds, 5 sets of blades (4 pieces per set, 20 pieces in total) and commonly used tools such as screwdrivers.

Pet food is very different from traditional feeding methods. Our floating extruded feed pellet machine uses corn, soybeans (bean cake) and other leftovers as raw materials. It can be directly added to the machine to extrude and produce different feed pellets, with novel shapes. With unique taste, rich nutrition and delicate organization, it is suitable for feeds of different general tastes such as dogs, cats, fish, birds, shrimps, tortoises, minks, foxes and so on. It is suitable for professional farmers, small and medium-sized feed factories and research institutions.

Many friends buy this machine to make floating fish feed pellets, please allow us to introduce more about it.

Floating fish feed pellet machine is widely used for producing grains into high-grade aquatic feed pellets for fish,catfish,shrimps, crab etc.

Floating fish feed pellet machine is widely used for producing grains into high-grade aquatic feed pellets for fish,catfish,shrimps, crab etc.

The Features of Floating Fish Feed Pellet Machine

1. Fish food made by this pellet extruder is of puffing type, more easily to digest for fishes.

2. The fish feed pellet size can be from 0.8-12 mm to feed different sizes of fishes.

3. The puffing fish feed pellets can float on the water surface without dissolution for over 12 hours. Will not pollute water quality.

4. High temperature and high pressure process can kill the salmonellosis and bacterial infections and also makes the pellets easily to digest.

1. Fish food made by this pellet extruder is of puffing type, more easily to digest for fishes.

2. The fish feed pellet size can be from 0.8-12 mm to feed different sizes of fishes.

3. The puffing fish feed pellets can float on the water surface without dissolution for over 12 hours. Will not pollute water quality.

4. High temperature and high pressure process can kill the salmonellosis and bacterial infections and also makes the pellets easily to digest.

The Application of Floating Fish Feed Pellet Machine

1. Make floating feed pellets for all kinds of fish, shrimp and other aquatics animals.

2. If you have fish ponds and aquatic farms, this machine is really cost-effective compared with buying expensive pellets.

1. Make floating feed pellets for all kinds of fish, shrimp and other aquatics animals.

2. If you have fish ponds and aquatic farms, this machine is really cost-effective compared with buying expensive pellets.

The Working Process of Floating Fish Feed Pellet Machine

When the raw material is sent into feeding device, they will be pressed by the screw shaft with high pressure and temperature which can make the raw material fully cooked and sterilized. Then the pressed material will be formed into pellets by shaping mold. After that a cutting device will cut the formed pellets into different length as required.

When the raw material is sent into feeding device, they will be pressed by the screw shaft with high pressure and temperature which can make the raw material fully cooked and sterilized. Then the pressed material will be formed into pellets by shaping mold. After that a cutting device will cut the formed pellets into different length as required.

Specification

|

Model

|

Power

|

Voltage

|

Cutting power

|

Feeding power

|

Capacity

|

Spiral diameter

|

Pellet size

|

|||||||

|

ML-40

|

5.5-7.5 kw

|

380V/50Hz

|

0.4 kw

|

0.4kw

|

40-50kg/h

|

40 mm

|

0.8-12 mm

|

|||||||

|

ML-60

|

15 kw

|

380V/50Hz

|

0.4 kw

|

0.4kw

|

100-120kg/h

|

60 mm

|

0.8-12 mm

|

|||||||

|

ML-60D (Diesel power)

|

22 HP

|

***

|

0.4 kw

220V 50Hz

|

0.4 kw

220V 5Hz

|

100-120kg/h

|

60 mm

|

0.8-12 mm

|

|||||||

|

ML-70

|

18.5 kw

|

380V/50Hz

|

0.4 kw

|

0.4 kw

|

150-180 kg/h

|

68-70 mm

|

0.8-12 mm

|

|||||||

|

ML-70D

(Diesel power)

|

28 HP

|

***

|

0.4 kw

220V 50Hz

|

0.4 kw

220V 5Hz

|

150-180 kg/h

|

68-70 mm

|

0.8-12 mm

|

|||||||

|

ML-80

|

22 kw

|

380V/50Hz

|

0.4 kw

|

0.4 kw

|

250-300 kg/h

|

80 mm

|

0.8-12 mm

|

|||||||

|

ML-90

|

30 kw

|

380V/50Hz

|

1.5 kw

|

0.75 kw

|

400 kg/h

|

90 mm

|

0.8-12 mm

|

|||||||

|

ML-100

|

37 kw

|

380V/50Hz

|

1.5 kw

|

0.75 kw

|

500 kg/h

|

100 mm

|

0.8-12 mm

|

|||||||

|

Each machine is equipped with 6 molds, 5 sets of blades (4 pieces per set, 20 pieces in total)

|

|

|

|

|

|

|

|

|||||||

Packing & Delivery

Hot Searches