- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220-440V

-

Power:

-

80KW

-

Dimension(L*W*H):

-

2.5*1.0*2m

-

Weight:

-

2 kg

-

Warranty:

-

12 months

-

Warranty of core components:

-

1 year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

semi automatic egg dish machine for egg tray food container

-

Production:

-

Egg Tray, Fruit Tray, Cup Carrier, Disposable Medical Care Products

-

Automation:

-

Semi Automatic

-

Forming Type:

-

Reciprocation egg tray machine

-

Capacity:

-

1000pcs/hour

-

Raw material:

-

Waste Paper

-

Application:

-

Packing Industry

-

Finished Products:

-

Egg Tray Egg Carton

Quick Details

-

Production Capacity:

-

20 PCS/MIN

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

ZH brand

-

Voltage:

-

220-440V

-

Power:

-

80KW

-

Dimension(L*W*H):

-

2.5*1.0*2m

-

Weight:

-

2 kg

-

Warranty:

-

12 months

-

Warranty of core components:

-

1 year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

semi automatic egg dish machine for egg tray food container

-

Production:

-

Egg Tray, Fruit Tray, Cup Carrier, Disposable Medical Care Products

-

Automation:

-

Semi Automatic

-

Forming Type:

-

Reciprocation egg tray machine

-

Capacity:

-

1000pcs/hour

-

Raw material:

-

Waste Paper

-

Application:

-

Packing Industry

-

Finished Products:

-

Egg Tray Egg Carton

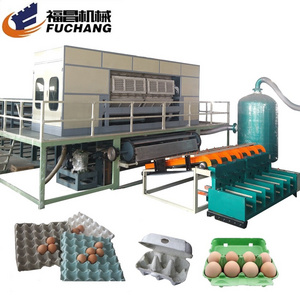

Small scale Low cost semi automatic egg dish machine for egg tray food container

E1000 forming machine (Semi automatic)

Advantage

A. semi auto paper egg tray machine suitable for family factory small factor

B. ZH brand egg tray machine, high quality assurance

C.1 year warranty

D. engineer overseas service

E. energy saving, water saving, oil saving

F. Included one set of forming machine; vacuum auto drain system and auto control cabinet. One piece of forming platen and transferring platen equipped. Platen size: 750*400mm. It can be mounted 2sets of 30-cell egg tray mold on the platen (3pcs/cycle). Cycle time: 15-20 seconds/cycle.

Features

Occupation: about 400m2.Requirement for the

Workshop: height ≥4.0m, width≥10m, length≥40m.

Total power for the production line: 61.2KW.

Workforce for the egg tray machine: 2 people/shift.

Capacity

|

Type of products |

30-cell egg tray |

12-cell egg carton/box |

10-cell egg carton/box |

6+6-cell egg carton/box |

6-cell egg carton/box |

Fruit tray |

Cup carrier |

|

capacity (PCS/HR) |

1000 |

1000 |

1000 |

1000 |

2000 |

800 |

1200 |

Consumption

| NO. | DESC | CONSUMPTION PER HOUR |

| 1 | Waste Paper | 75-80kg |

| 2 | Electricity | 75-80kw |

| 3 | Water | 0.5-1.2T |

Pictures together with customer

Fully Atutomatic Rotary Forming Machine

The fully automatic rotary forming machine line is for medium and large capacity production, such as 2000pcs/hr, 3000pcs/hr, 3600pcs/hr, 4000pcs/hr, 5000pcs/hr, 6000pcs/hr, etc for choice.

There are some kinds of specification of 2 face platens, 4 face platens, 6 face platens, 8 face platens and other specifications for the rotary machine; and single layer drying line and multi-layer drying line for choose. The drying line can use diesel oil, LPG, natural gas, coal, charcoal and steam heating, etc.

Full Automatic Rotary Forming machine production line Specification

|

Capacity |

Pulping Machine Parameter |

Forming Machine Parameter |

Drying Line Parameter |

|

2250pcs/hr |

Effective Volume 2m3 Power 30kw |

two-Face forming platens, one-face transferring platen. Mold Platen Size 1200×440mm |

Dimension 11100×1530×2550mm Energy: Natural Gas/LPG/Coal(Steam/Thermal Oil) |

|

3000pcs/hr |

Effective Volume 3m3 Power 30kw |

Two-face forming platen, one-face transferring platen. Mold Platen Size 1500×440mm |

Dimension 11100×1880×2550mm Energy: Natural Gas/LPG/Coal(Steam/Thermal Oil) |

|

3600pcs/hr |

Effective Volume 3m3 Power 30kw |

Two-face forming platens, one transferring platen. Mold Platen Size 1800×440mm |

Dimension 11100×2230×2550mm Energy: Natural Gas/LPG/Coal(Steam/Thermal Oil) |

|

5000pcs/hr |

Effective Volume 3m3 Power 55kw |

Four face forming platens, one transferring platen. Mold platen size: 1500×440mm |

Dimension 14800×1880×2550mm Energy: Natural Gas/LPG/Coal(Steam/Thermal Oil) |

| 6000pcs/hr |

Effective Volume 3m3 Power 55kw |

Four face forming platens, one transferring platen. Mold platen size: 1800×440mm |

Dimension 14800×2230×2550mm Energy: Natural Gas/LPG/Coal(Steam/Thermal Oil) |

|

Description: The production line capacity isbased on the 30 cell egg tray. (Mold size: 300×290mm, weight: 70g) For different capacity and other products of the production line, it can be customized according to clients' requirement. |

|||

The Advantages of Paper Pulp Molding Production Line

1. Waste paper Recycling with low cost

Its raw material are any kind of papers, like wasted newspaper, carton, printers or leftover bits in paper mill, convenient to collect with low cost. The cost of pulp molding product is much lower than EPS products.

2. Best environmental protection:

non-environmental pullution during the whole process of production, utility and waste treatment: no waste water consumption with water recycling, no waste materials with waste paper recycling, and non-environmental pullution.

3. Recycling use

low recycling cost and it can be used repeatedly. Biodegradable as vegetable fiber during one or two month. The finished products can be stacked, space-saving.

4. Good Market prospect

There is a restriction in developed country such as Europe, America ans Japan for importing EPS products, and advocate the use of enviromental packaging materials, encourage for Eco-package replaced of EPS packages in order to reject white pollution.

5. Good Performance.

Anti-shack, anti-static electricity, better efficiency than EPS, PS and PVC products.

Application

The machine mainly produce large quantity and easy structure pulp products such as egg tray, egg carton,fruit tray, fruit tray, coffee cup tray, medical tray and so on.

Applicable industries: poultry, animal husbandry, agriculture, carton production industry, printing industry, paper industry, etc.

Range and specification of Paper Pulp Products

FAQ

1.What kind of material we can use as the material?

Any kinds of waste paper or used paper products like old newspaper,magazines,books, used boxes, abandoned cartons etc, and easy to collect the raw materials.

2.What kind of Fuel can be used for the whole production line?

Generally the fuel is coal,natural gas,dieseal oil.

3.What kind of products can be made by this machine?

All paper product trays and cartons like paper egg tray,egg carton,egg box,fruit tray,bottle tray, plate and tableware, electric product packing, disposable tray, shoes tray etc.

|

Model |

Capacity |

Automation |

Dryer |

forming type |

|

600pcs/hour |

Semi auto |

No |

Reciprocating |

|

|

800pcs/hour |

Semi auto |

No |

Reciprocating |

|

|

1000pcs/hour |

Semi auto/Full auto |

For choice |

Reciprocating |

|

|

1500pcs/hour |

Semi auto/Full auto |

For choice |

Reciprocating |

|

|

2000pcs/hour |

full auto |

multilayer |

Rotary |

|

|

3000pcs/hour |

full auto |

multilayer |

Rotary |

|

|

4000pcs/hour |

full auto |

multilayer |

Rotary |

|

|

E8000 (click to view more) |

8000pcs/hour |

Full auto |

multiayer |

Rotary |

|

10000pcs/hr |

Full auto |

multilayer |

Double rotary |

|

|

15000pcs/hour |

Full auto |

multilayer |

Double rotary |