- Product Details

- {{item.text}}

Quick Details

-

Usage:

-

Pipe Welding

-

Dimensions:

-

Client's Requirement

-

Weight (KG):

-

1000 KG

-

Name:

-

Conventional welding rotator

-

Roller material:

-

Rubber or PU or Metal

-

Certificates:

-

CE ISO

-

Max load weight:

-

250000kg or as your request

-

range of suitable workpiece:

-

1200-7000mm or as your request

-

diameter and width:

-

700*280mm or as your request

-

Voltage:

-

220-470V

-

Motor Power:

-

2*5.5KW

-

Wheel linear speed:

-

6-60m/h

-

Way of setting:

-

AC Converter Stepless Speed Adjust or electro-magnetic speed adjust

Quick Details

-

Marketing Type:

-

New Product 2021

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Zhouxiang

-

Usage:

-

Pipe Welding

-

Dimensions:

-

Client's Requirement

-

Weight (KG):

-

1000 KG

-

Name:

-

Conventional welding rotator

-

Roller material:

-

Rubber or PU or Metal

-

Certificates:

-

CE ISO

-

Max load weight:

-

250000kg or as your request

-

range of suitable workpiece:

-

1200-7000mm or as your request

-

diameter and width:

-

700*280mm or as your request

-

Voltage:

-

220-470V

-

Motor Power:

-

2*5.5KW

-

Wheel linear speed:

-

6-60m/h

-

Way of setting:

-

AC Converter Stepless Speed Adjust or electro-magnetic speed adjust

Products Description

Parameter

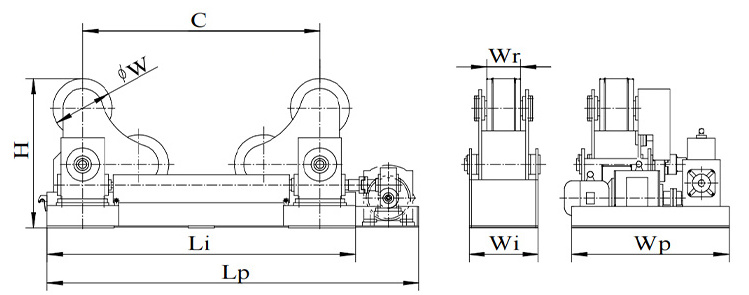

The turning roll is designed to aid the welding of tanks. By using independent drive and idler units, tanks of varying lengths can be placed on the turning rolls supported on the turning rolls wheels. The power welding rotator and the passive welding rotator can be moved on the track, and the distance between them can be adjusted to weld cylinders of different lengths.

Heavy Duty Multifunction Pipe Roller Stands 100 Ton Welding Rotator 1 Ton Welding Turning Rolls

The wheels of self aligned welding rotator can be opened on the base frame to accommodate different vessel diameters. Our heavy duty, built to last self aligned welding rotators are designed and manufactured to tolerate the hardest, hard-wearing and unrelenting workload environments.

Heavy Duty Pipe Roller Stands 100 Ton Welding Rotator 1 Ton Welding Turning Rolls

|

Model

|

Load & Rotation Capacity

(Ton)

|

Tanks Diameter Range (mm)

|

Rotation Speed (mm/min)

|

Driven Motor Power (Kw)

|

Frame Center

Distance

|

Wheels

Diameter & Width

|

Roll Dimensions (mm)

|

|

|

|

|

|

|

|

|

C (mm)

|

ΦW * Wr (mm)

|

Lp * Wp * H

|

Li * Wi * H

|

|

|

GLHZ-5

|

5

|

250-2300

|

100-1000 Speed adjusted by VFD

|

0.75

|

940

|

250*140

|

1560*695*692

|

1240*380*692

|

|

|

GLHZ-10

|

10

|

320-2800

|

|

1.5

|

1100

|

300*150

|

1800*705*805

|

1440*400*805

|

|

|

GLHZ-20

|

20

|

500-3500

|

|

2.2

|

1400

|

350*180

|

2180*910*895

|

1780*480*895

|

|

|

GLHZ-40

|

40

|

600-4200

|

|

3

|

1600

|

400*200

|

2448*1000*1018

|

2040*530*1018

|

|

|

GLHZ-60

|

60

|

750-4800

|

|

4

|

1800

|

450*220

|

2770*1100*1095

|

2340*585*1095

|

|

|

GLHZ-80

|

80

|

850-5000

|

|

4

|

2000

|

500*240

|

2975*1165*1198

|

2540*620*1198

|

|

|

GLHZ-100

|

100

|

1000-5500

|

|

5.5

|

2200

|

500*280

|

3380*1405*1320

|

2800*730*1320

|

|

|

GLHZ-150

|

150

|

1100-6000

|

|

7.5

|

2500

|

600*280

|

3870*1600*1550

|

3240*800*1550

|

|

|

GLHZ-250

|

250

|

1200-7000

|

|

2*5.5

|

2800

|

700*300

|

4468*1620*1785

|

3620*860*1785

|

|

|

GLHZ-500

|

500

|

1800-8000

|

|

2*7.5

|

3500

|

850*350

|

5562*1784*2062

|

4420*950*2062

|

|

|

Model

|

Load & Rotation Capacity

(IBS)

|

Tanks Diameter Range (in)

|

Rotation Speed (mm/min)

|

Driven Motor Power (HP)

|

Frame Center

Distance

|

Wheels

Diameter & Width

|

Roll Dimensions (mm)

|

|

|

|

|

|

|

|

|

C (mm)

|

ΦW * Wr (mm)

|

Lp * Wp * H

|

Li * Wi * H

|

|

|

GLHZ-5

|

11,000

|

9 27/32--90 35/64

|

100-1000 Speed adjusted by VFD

|

1.0

|

940

|

250*140

|

1560*695*692

|

1240*380*692

|

|

|

GLHZ-10

|

22,000

|

12 19/32--110 15/64

|

|

2.0

|

1100

|

300*150

|

1800*705*805

|

1440*400*805

|

|

|

GLHZ-20

|

44,000

|

19 11/16--137 51/64

|

|

3.0

|

1400

|

350*180

|

2180*910*895

|

1780*480*895

|

|

|

GLHZ-40

|

88,000

|

23 5/8--165 23/64

|

|

4.0

|

1600

|

400*200

|

2448*1000*1018

|

2040*530*1018

|

|

|

GLHZ-60

|

132,000

|

29 1/2--188 31/32

|

|

5.4

|

1800

|

450*220

|

2770*1100*1095

|

2340*585*1095

|

|

|

GLHZ-80

|

176,000

|

33 15/32--196 27/32

|

|

5.4

|

2000

|

500*240

|

2975*1165*1198

|

2540*620*1198

|

|

|

GLHZ-100

|

220,000

|

39 3/8--216 17/32

|

|

7.4

|

2200

|

500*280

|

3380*1405*1320

|

2800*730*1320

|

|

|

GLHZ-150

|

330,000

|

43 5/16--236 7/32

|

|

10.0

|

2500

|

600*280

|

3870*1600*1550

|

3240*800*1550

|

|

|

GLHZ-250

|

550,000

|

47 1/4 --275 19/32

|

|

15.0

|

2800

|

700*300

|

4468*1620*1785

|

3620*860*1785

|

|

|

GLHZ-500

|

1,100,000

|

59 1/16--314 31/32

|

|

20.0

|

3500

|

850*350

|

5562*1784*2062

|

4420*950*2062

|

|

Product Advantages

Heavy Duty Multifunction Pipe Roller Stands 100 Ton Welding Rotator 1 Ton Welding Turning Rolls

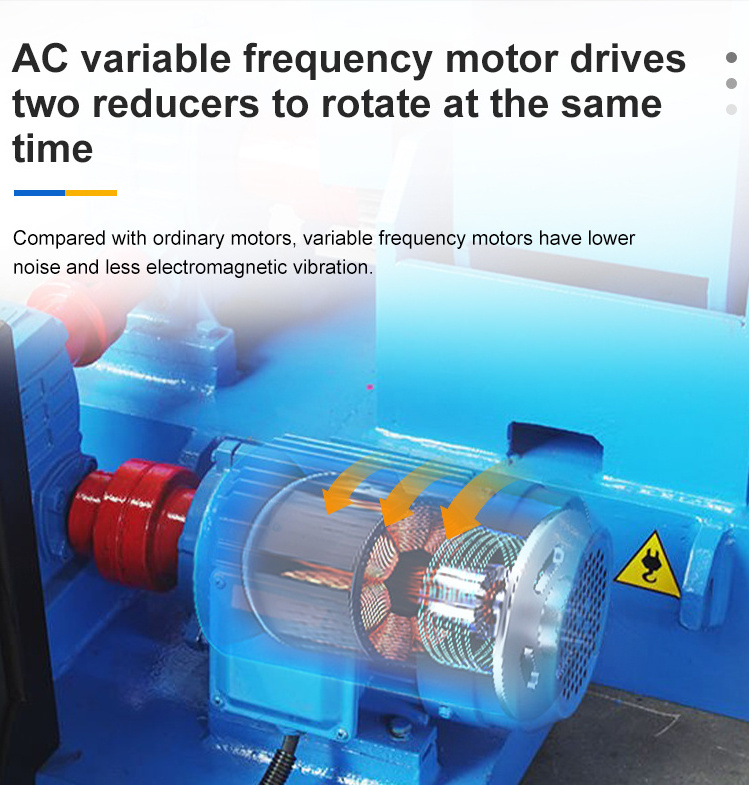

The self-aligned welding rotator is driven by one AC variable frequency motor to drive two gear reducers to rotate at the same time. Compared with ordinary motors, variable frequency motor has lower noise and smaller electromagnetic vibration.

Heavy Duty Multifunction Pipe Roller Stands 100 Ton Welding Rotator 1 Ton Welding Turning Rolls

Heavy Duty Multifunction Pipe Roller Stands 100 Ton Welding Rotator 1 Ton Welding Turning Rolls

Schneider AC variable frequency governor is mainly used to control and adjust the speed of three-phase AC asynchronous motors, with stable performance, rich combination functions, good dynamic characteristics, super overload capacity and unparalleled flexibility. The linear speed of the roller is 100-1000 mm/min, the adjustment response accuracy is high, and the speed operation is stable and

reliable.

Heavy Duty Multifunction Pipe Roller Stands 100 Ton Welding Rotator 1 Ton Welding Turning Rolls

IP65 ingress protection electric cabinet has the protection function for field use。The wiring is neat and the grounding signs are clear.The operation panel has the functions of forward、reverse and stop. The speed is adjusted by the rotary button and displayed on the display screen.

Compared with ordinary rubber wheels, PU rollers have better bearing effect, wear resistance, acid resistance and high temperature resistance.

Compared with ordinary bearings, the imported bearings has the advantages of higher limit speed, higher load resistance, lower noise and longer service life. Greatly improved the quality of our products.

Packing & Shipping

Customer Photos

Why Choose Us

Wuxi Zhouxiang Complete Set of Welding Equipment Co.,Ltd,founded in 1991,located in Wuxi city, about 100km from Shanghai.We have fixed assets of 150 million yuan,cover an area of 160,000 m2, staff 500 people,including more than 100 engineering and technical personnel.Our company was certified to ISO9001 Quality System Certification firstly in the industry and many products were certified to China Compulsory Certification(CCC).Our products sell well at home and abroad,including Europe,America,Southeast Asia,Middle East and other countries.

Zhouxiang products mainly include cnc cutting machine,H beam production line,box beam production line, welding manipulator, welding rotator, welding positioner, milling machine, shot blasting machine, plate rolling machine, profile bending machine and fiber laser cutting machine etc.We have high sincerity to do business with customers all over the world and establish good friendships.

Heavy Duty Pipe Roller Stands 100 Ton Welding Rotator 1 Ton Welding Turning Rolls

We actively participate in and hold exhibitions, and reach friendly cooperation with foreign friends. Our cooperation is not only our progress but also the world's progress!

200t Automatic Pipe Welding Turning Roll 10 Ton 100 Ton Welding Rotator

Our Service

FAQ

Heavy Duty Multifunction Pipe Roller Stands 100 Ton Welding Rotator 1 Ton Welding Turning Rolls

1.Q: What is the minimum order quantity?

A: 1PCS.

Heavy Duty Multifunction Pipe Roller Stands 100 Ton Welding Rotator 1 Ton Welding Turning Rolls

2.Q: What are the payment terms?

A: L/C; T/T.

Heavy Duty Multifunction Pipe Roller Stands 100 Ton Welding Rotator 1 Ton Welding Turning Rolls

3.Q: How long is the delivery time?

A: 30 Days.

Heavy Duty Multifunction Pipe Roller Stands 100 Ton Welding Rotator 1 Ton Welding Turning Rolls

4.Q:How long is the warranty period?

A: 1 Years.

Hot Searches