- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

3-phase 4-wires, 380V, 50Hz

-

Dimension(L*W*H):

-

1100mm*1100mm*1550mm

-

Power (kW):

-

26

-

Weight (KG):

-

460 KG

-

After-sales Service Provided:

-

Overseas third-party support available

-

Product Name:

-

New polyurea waterproofing foam spray machine for sale

-

Material:

-

polyol and ISO

-

Application:

-

Spray Wall or others

-

Item:

-

two components electric spray equipment JHPK-DD3

-

Ratio of raw materials:

-

1:1

-

Viscosity range:

-

200~1000CPS

-

Output of raw materials:

-

2~8L/ min

-

Hydraulic working pressure:

-

8~12 Mpa(1160~1740psi)

-

Certification:

-

ce

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

JHPK

-

Machine Type:

-

FOAM

-

Voltage:

-

3-phase 4-wires, 380V, 50Hz

-

Dimension(L*W*H):

-

1100mm*1100mm*1550mm

-

Power (kW):

-

26

-

Weight (KG):

-

460 KG

-

After-sales Service Provided:

-

Overseas third-party support available

-

Product Name:

-

New polyurea waterproofing foam spray machine for sale

-

Material:

-

polyol and ISO

-

Application:

-

Spray Wall or others

-

Item:

-

two components electric spray equipment JHPK-DD3

-

Ratio of raw materials:

-

1:1

-

Viscosity range:

-

200~1000CPS

-

Output of raw materials:

-

2~8L/ min

-

Hydraulic working pressure:

-

8~12 Mpa(1160~1740psi)

-

Certification:

-

ce

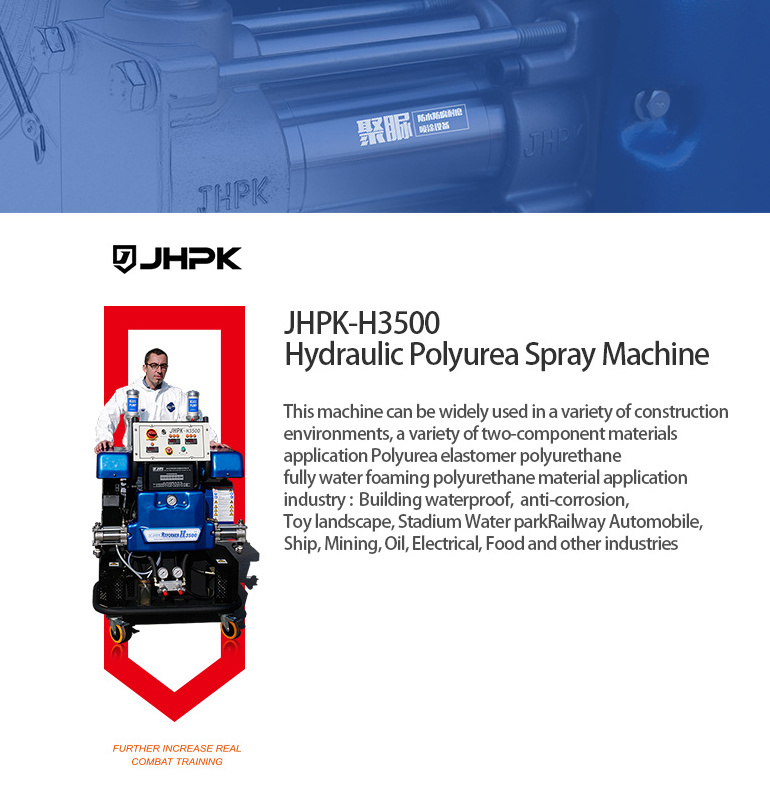

Descrition:

Our company has obtained Quality Management System Certificates ISO9000.

The advanced management system and high efficient and modern production mode provide reliable quality assurance for our products.

Beijing Jinghua Park Polyurethane Equipment Co., Ltd freshly launched the double component system of hydraulic spraying equipment.

This kind of machine can be used in many areas and spray a lot of double component materials, such as spray a variety of two-component materials: polyurea elastomer, polyurethane elastomer, polyurethane foam and polyurea,polyurethane adhesive and sealants.

The advantages of this kind of machine:

1. It’s very convenient to moving more suitable for factory and construction contractor.

2. It provides the maxim function for the working.

3. It has the special FGPQ spray gun, simple operation, spray a better effect.

Main equipment: 1 set

Spray gun: 1 piece

Heating pipe: 15 m (50ft)

3m pipe connecting to the gun: 1 set

Feeding pump: 2 sets

Spare parts :1 set

Tools :1 set

English manual: 1 set

Package: plywood tray

Ratio of raw materials: 1:1

Viscosity range: 200~1000CPS

Output of raw materials: 2~8L/ min

Heating power: 9000W*2

Hose heating power: 3200W

Heating temperature range: 0℃~90℃(32°F~194°F)

Power source: 3-phase 4-wires, 380V, 50Hz

Hydraulic working pressure: 8~12 Mpa(1160~1740psi)

Maximum pressure: 26Mpa(3770psi)

Max. length (optional): 90m(300ft)

Gun cleaning way: high pressure mechanical cleaning

Driven way: hydraulic driven

Dimension: 1100mm*1100mm*1550mm

Weight: 350Kg

Descrition:

Our company has obtained Quality Management System Certificates ISO9000.

The advanced management system and high efficient and modern production mode provide reliable quality assurance for our products.

Beijing Jinghua Park Polyurethane Equipment Co., Ltd freshly launched the double component system of hydraulic spraying equipment.

This kind of machine can be used in many areas and spray a lot of double component materials, such as spray a variety of two-component materials: polyurea elastomer, polyurethane elastomer, polyurethane foam and polyurea,polyurethane adhesive and sealants.

The advantages of this kind of machine:

1. It’s very convenient to moving more suitable for factory and construction contractor.

2. It provides the maxim function for the working.

3. It has the special FGPQ spray gun, simple operation, spray a better effect.

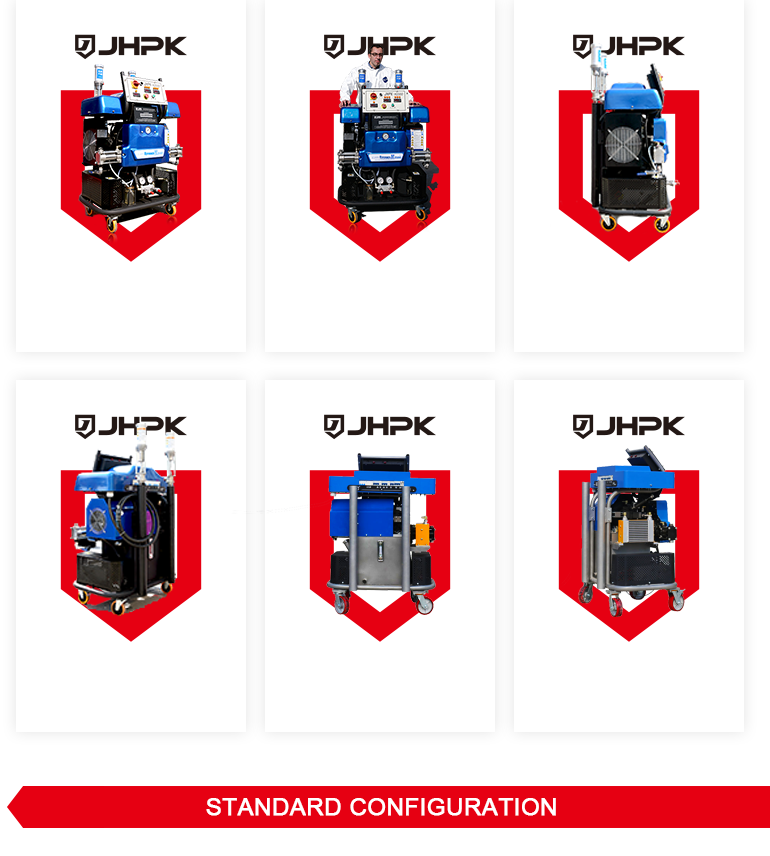

Standard Configuration:

|

Main equipment: |

1 set |

|

Nozzle: |

1 piece |

|

Heating tube per group: |

15m(50ft) |

|

Short tube with nozzle per group: |

3m(10ft) |

|

Feeding pump: |

2 sets |

|

Spare parts: |

1 set |

|

Tool: |

1 set |

|

English manual: |

1 set |

|

Package: |

plywood tray |

Technical Data:

|

Proportion of raw material: |

1:1 |

|

Viscosity range of raw material: |

200-1000 CPS (under operation temperature) |

|

Output of raw material: |

2-8 L/min |

|

Heating power: |

9000W*2 |

|

Hose heating power: |

3200W |

|

Maximum pressure |

26Mpa(3770psi) |

|

Heating temperature range: |

0℃~90℃ |

|

Electrical source: |

3 phase 4 wire, 380V 50Hz |

|

Compressed air: |

0.5~0.8Mpa(70~120psi)≥ 1m3/min |

|

Hydraulic working pressure |

8~12Mpa(1160~1740psi) |

|

Max. length (optional): |

90m(300ft) |

|

Gun cleaning way |

high pressure mechanical cleaning |

|

Driven way |

hydraulic driven |

Shipping Parameter:

|

Dimension: |

1100mm×1100mm×1550mm |

|

Weight: |

350Kg |