Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Supplier Type:

-

OEM ODM EMS

-

Copper Thickness:

-

Customize, 0.5oZ~12oZ

-

Service:

-

One-stop Turnkey PCBA Service

-

Certificate:

-

ISO9001/FCC/CE/ROHS

-

Testing Service:

-

AOI X-Ray Function Test

-

Solder mask color:

-

Blue.green.red.black.white.etc

-

Application:

-

Electronics Device

-

Layer:

-

1-64 Layers

-

PCBA service:

-

OEM ODM EMS

-

Base Material:

-

FR-4/aluminum/ceramic/cem-3/FR-1

-

MOQ:

-

1 PCS

Quick Details

-

Model Number:

-

221230-09

-

Place of Origin:

-

GUA

-

Brand Name:

-

Custom

-

Supplier Type:

-

OEM ODM EMS

-

Copper Thickness:

-

Customize, 0.5oZ~12oZ

-

Service:

-

One-stop Turnkey PCBA Service

-

Certificate:

-

ISO9001/FCC/CE/ROHS

-

Testing Service:

-

AOI X-Ray Function Test

-

Solder mask color:

-

Blue.green.red.black.white.etc

-

Application:

-

Electronics Device

-

Layer:

-

1-64 Layers

-

PCBA service:

-

OEM ODM EMS

-

Base Material:

-

FR-4/aluminum/ceramic/cem-3/FR-1

-

MOQ:

-

1 PCS

Our Strength

Fumax’s mission is to provide the solution of choice for OEMs who need a focused and responsive design and manufacturing partner for medium-volume, complex electronic products.

We have achieved and constantly renew all the certificates including ISO90001, CE, FCC, UL, and ROHS, to guarantee the highest quality products.

We have achieved and constantly renew all the certificates including ISO90001, CE, FCC, UL, and ROHS, to guarantee the highest quality products.

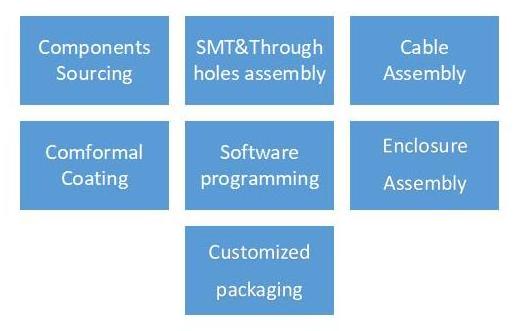

Special Service

One-stop Turnkey Service In PCB&PCBA

Great Production Capacity:

10 high speed SMT lines

8 DIP soldering lines

4 Final Assembly lines

Daily output:

Sub-assemblies = est. 150K

Full assemblies = est. 60K

Product Testing = est. 60K

Product package = est. 200K

Note: The actual production

output will vary per different

products.

8 DIP soldering lines

4 Final Assembly lines

Daily output:

Sub-assemblies = est. 150K

Full assemblies = est. 60K

Product Testing = est. 60K

Product package = est. 200K

Note: The actual production

output will vary per different

products.

Manufacturing Process:

IQC (Incoming material checking)

Solder Paste Printing

SPI

SMT (BGA, QFN, 0201…etc)

Reflow Soldering (10 temp zone)

AOI (Auto Optical Inspection)

X-ray

ICT (In Circuit Testing)

DIP (Through-hole assembly)

Wave Soldering

Solder Paste Printing

SPI

SMT (BGA, QFN, 0201…etc)

Reflow Soldering (10 temp zone)

AOI (Auto Optical Inspection)

X-ray

ICT (In Circuit Testing)

DIP (Through-hole assembly)

Wave Soldering

Board Cleaning

Firmware programming

Function testing

Board Coating

Reliability testing (burn/in

life tests)

FQC (Final Quality Checking)

Package

Firmware programming

Function testing

Board Coating

Reliability testing (burn/in

life tests)

FQC (Final Quality Checking)

Package

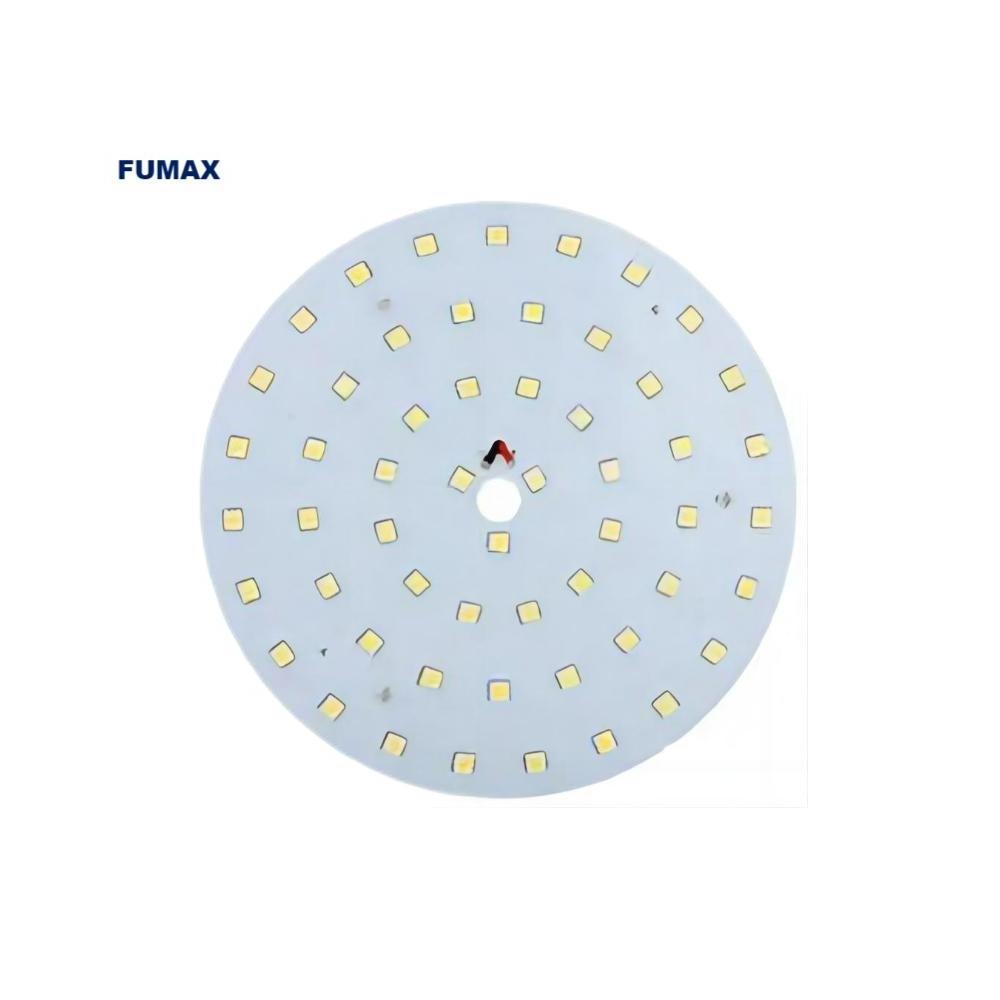

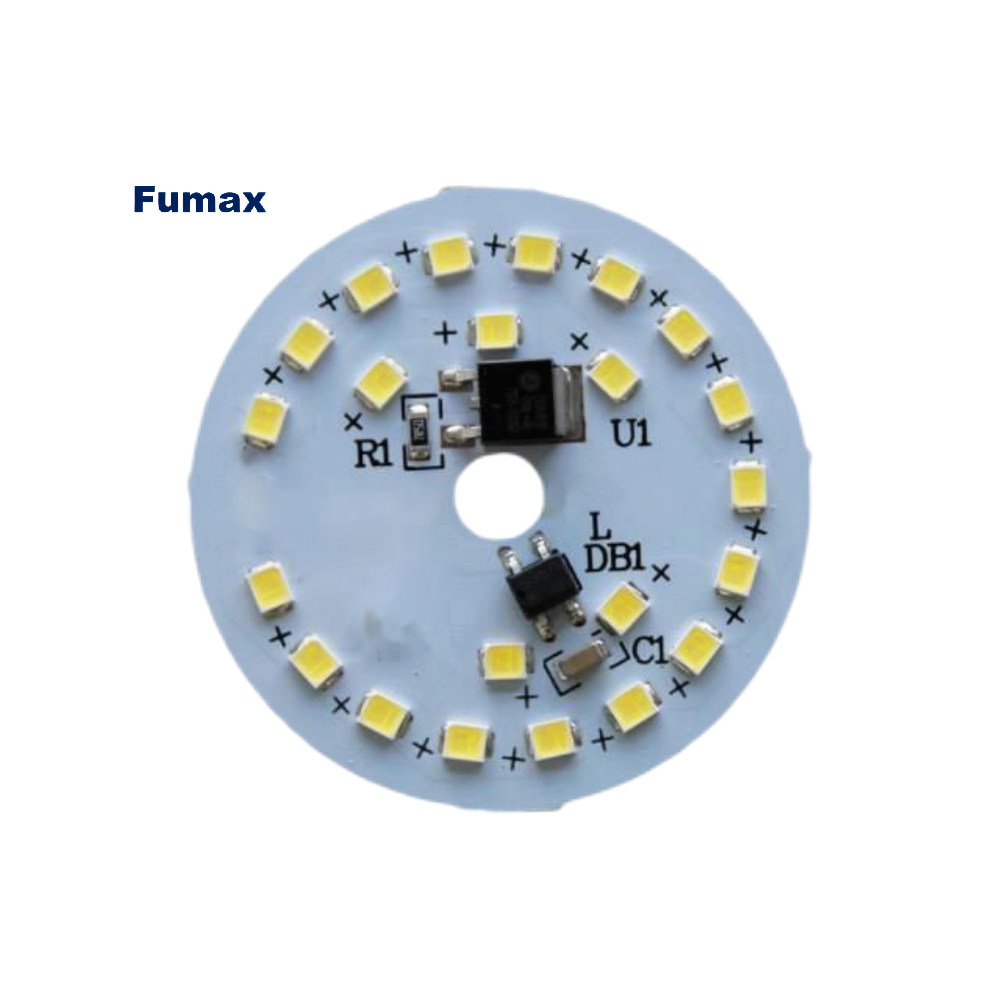

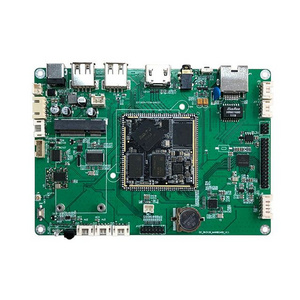

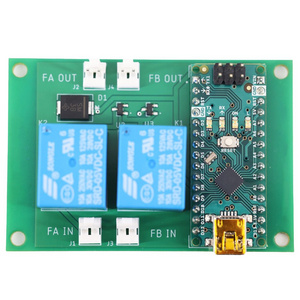

Main Product

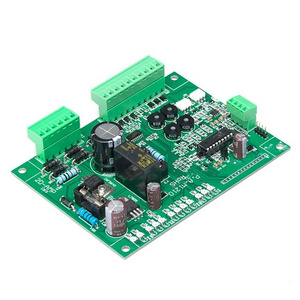

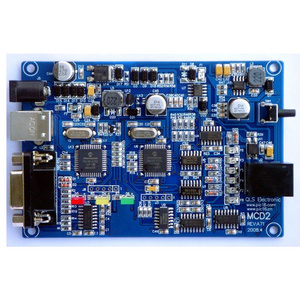

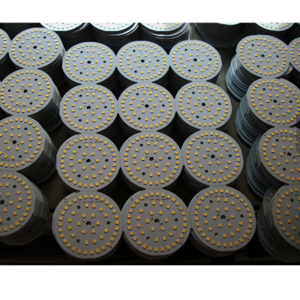

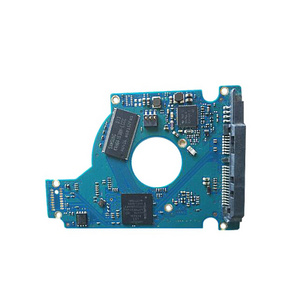

PCB

PCBA

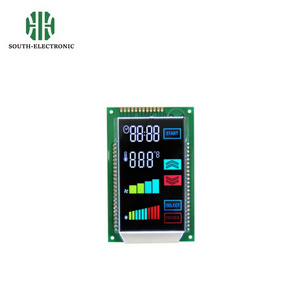

FINISHED GOODS

Hot Searches