- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

40GP Container

-

Year:

-

2023

-

Power (kW):

-

7000 kW

-

Weight (KG):

-

10000 KG

-

Name of machine:

-

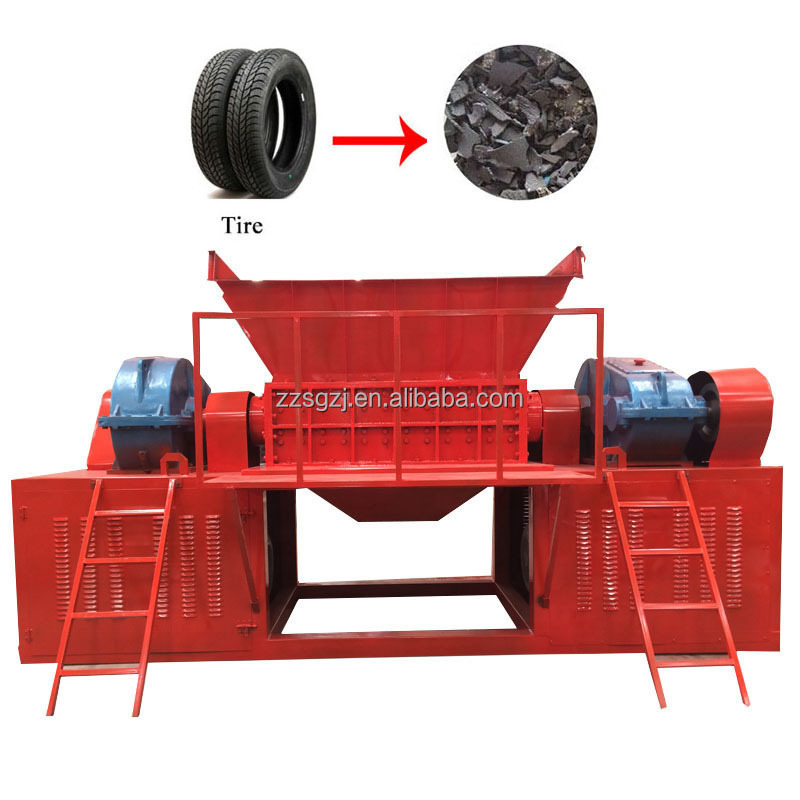

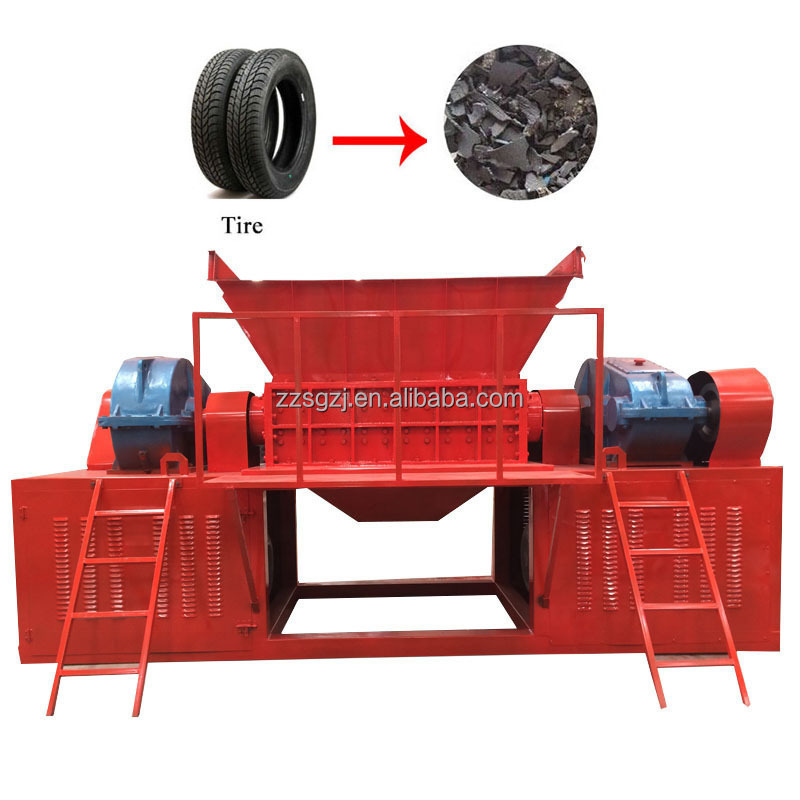

tyre recycling machine

-

Application:

-

Making rubber particle

-

Output size:

-

1-5mm

-

Inlet size:

-

tire (less than 1200 diameter)

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Tyre type:

-

car tire,truck tire etc.

-

Capacity:

-

about 500kg/h

-

Usage:

-

playground rubber track,rubber floor etc.

-

Layout:

-

Whole production line

-

After Warranty Service:

-

Field maintenance and repair service

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shuguang

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

40GP Container

-

Year:

-

2023

-

Power (kW):

-

7000 kW

-

Weight (KG):

-

10000 KG

-

Name of machine:

-

tyre recycling machine

-

Application:

-

Making rubber particle

-

Output size:

-

1-5mm

-

Inlet size:

-

tire (less than 1200 diameter)

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Tyre type:

-

car tire,truck tire etc.

-

Capacity:

-

about 500kg/h

-

Usage:

-

playground rubber track,rubber floor etc.

-

Layout:

-

Whole production line

-

After Warranty Service:

-

Field maintenance and repair service

1.First, the steel wire tire decomposing equipment decomposes the steel wire tire into blocks.

2.Then the tire block is broken into (5-10cm) blocks by the tire shredder.

3.After the steel wire separator: the rubber and the steel wire are separated and processed into rubber particles. (10mm-20mm).

4. In the rubber pellet machine: crush the rubber particles to a smaller size (1mm-7mm).

5.After passing through the vibrating screen: sort the rubber particles of different sizes, and send the oversized particles back to the crusher Carry out secondary pulverization,.

6.Then fiber separator: remove foreign matter and fibers, then enter the rubber mill at room temperature for fine grinding,processed into fine rubber powder with a fineness of 5-80 mesh,

7.Finally bagged after a magnetic separation process Sales.

|

|

|

|

|

|

||

1.Tire wire drawing machine

Pull out the bead wires inside tires’ side walls completely before cutting and shredding processed.

2.Tire Shredder

After seperated with the steel wire,the tire will be conveyed into shredder machine,the remain tire will be shreded to about 30-50mm pieces size.

3.Rubber granulator machine

The rubber granulator machine we produce is a rubber granule machine for dust removal, crushing and screening. The pulverized rubber granules are angular and ribbed, the shape is uniform, the appearance is good, and at the same time, rubber particles with uniform particle size were screened out.It is special equipment for rubber floor tiles.

|

Model

|

Weight

|

Power

|

Capacity

|

|

TG-26

|

1ton

|

15kw

|

1000kg/h

|

|

Item Name

|

Description

|

|

Processed Materials

|

whole tire with diameter 600 mm, 1200 mm ,etc

|

|

Tire Ring Cutter

|

Capacity:30-60pieces/hour

|

|

Wire Drawing Machine

|

Capacity:20-30pieces/hour

|

|

Primary Shredder

|

Model: SG 1200 Blade:400*40

|

|

Secondary Shredder

|

Model: SG 1000 Blade:300*30

|

|

Primary Pulverizer

|

Power:22KW

|

|

Secondary Pulverizer with Screen

|

Power:30KW

|

|

Magnetic Separation Belt Conveyor

|

B500 B650 ,etc

|

|

Belt Conveyor

|

B500 B650 ,etc

|

Pre-Sales Service

* Inquiry and consulting support.

* View our Factory.

After-Sales Service

* Engineers available to service machinery overseas.