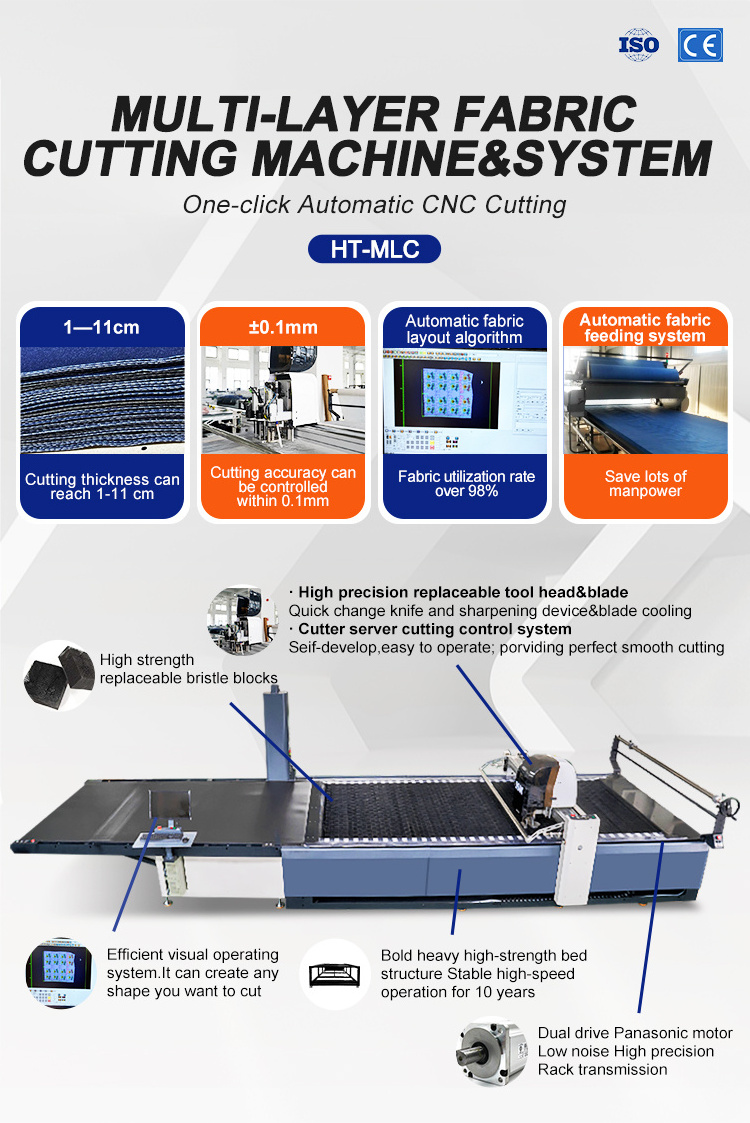

——Intelligent graphic layout software, it can achieve

any shape

you want to cut, material

utilization rate 98%,

i

ncrease material savings.

——

High speed cutting blade, capable of achieving a cutting

speed of 70m/min

, completely liberating manpower.

——Equipped with crawler conveyor,

automatic feeding and receiving

, comp

letely

s

ave labor costs

.

——

High speed cameras can achieve precise positioning of cutting shapes and control cutting

errors within 0.1mm

.

——We are a

real

cutting machine

factory

with R&D and production capabilities,welcome visit!