- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50Hz

-

Dimension(L*W*H):

-

2700x2620x2650mm

-

Weight (KG):

-

10000

-

Power (kW):

-

22

-

process material:

-

metal, nonmetal

-

workpiece:

-

piston ring, bearing, valve, seal,ceramic,etc.

-

Precision:

-

0.001mm

-

Diameter of parts:

-

12-120mm

-

Thickness of parts:

-

1-40mm

-

Feeding carrier motor power:

-

1.5kw

-

Max. Grinding Length:

-

40mm

-

Power(W):

-

22Kw x 2

-

Max. Grinding Diameter:

-

120mm

Quick Details

-

Year:

-

2020

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

YUHUAN

-

Voltage:

-

380V 50Hz

-

Dimension(L*W*H):

-

2700x2620x2650mm

-

Weight (KG):

-

10000

-

Power (kW):

-

22

-

process material:

-

metal, nonmetal

-

workpiece:

-

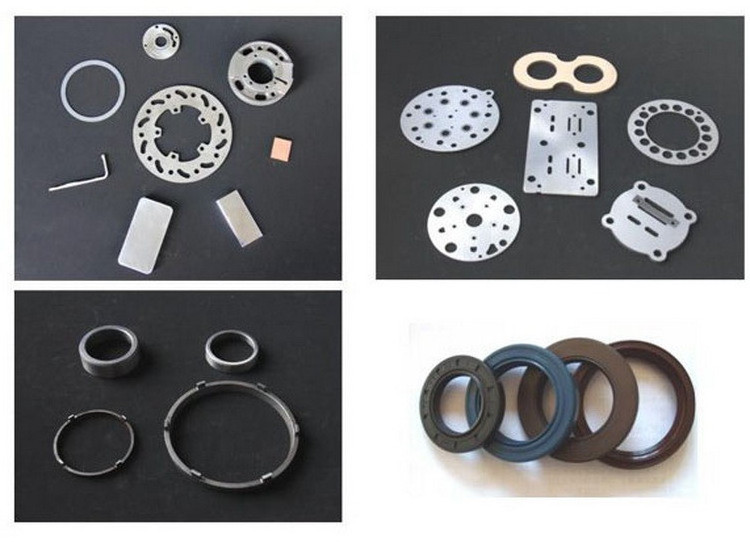

piston ring, bearing, valve, seal,ceramic,etc.

-

Precision:

-

0.001mm

-

Diameter of parts:

-

12-120mm

-

Thickness of parts:

-

1-40mm

-

Feeding carrier motor power:

-

1.5kw

-

Max. Grinding Length:

-

40mm

-

Power(W):

-

22Kw x 2

-

Max. Grinding Diameter:

-

120mm

Main purpose

It's designd for grinding parts with two parallel grinding wheels simultaneously. Various high precision and thin parts with parallel side surfaces, no matter they are made in metal or nonmetal material, can be processed. Such as bearing, valve,seal, oil pump vane, piston ring,ceramics,etc.

Technical characters:

1. CNC system chooses Mitsubishi E60 withfriendly interactive interface and reliable performance.

2. The parts’ processingfor the upper and lower surfaces is simultaneous with high precision, and without assisted positioning ( such as disks )

3. The program about the double disc grinding and wheel dressing control makes itto get high precision grinding.

4. Wheel head feed adopts precise ball screwunit. Feeding scale value: 0.001 mm.

5. Wheel head spindle is driven byconverter, 150-950r/min.

6. The motor of the feeding carrier adoptsconverter control; the speed is 1-10rpm.

7. Filtered by magnetic and paper tapetwo steps, the coolant recycle after oil temperature controll er.

8. Adopt hinged carrier plate mechanism(Patent No:ZL200820052659.1), which is easy to open to make aconvenient change and dressing of the grinding wheel..

9. Themachine body adopts casting boxlike structure with good shock absorption andreliable rigidity and thermal stability; Wheel heads spindle are set byvertical configuration.

Our company has modern production workshop, Complex efficient grinding Laboratory , Computer Design Studio , has a variety of testing instruments and equipment over 30 sets of experimental facilities , a variety of processing equipment over 60 sets .

Our company has modern production workshop, Complex efficient grinding Laboratory , Computer Design Studio , has a variety of testing instruments and equipment over 30 sets of experimental facilities , a variety of processing equipment over 60 sets .

1.Fumigated wooden packages with IPPC stamp.

1.Fumigated wooden packages with IPPC stamp.

2.Special packing requirements available.