- Product Details

- {{item.text}}

Quick Details

-

Other Name:

-

steel frame parking shed

-

Drawing design:

-

AutoCAD ; Tekla

-

Finish treatment:

-

Hot-dip Galvanization or Paint

-

Characteristic:

-

frame truss structure

-

Color:

-

Blue; Green; Darkgray; Client's Request

-

Material:

-

Q235/Q345 Low Carbon Steel

-

Warranty:

-

One Year

-

Steel frame durable years:

-

50 years

-

Delivery time:

-

Shipping in 45 days after payment

Quick Details

-

Grade:

-

Light steel structure

-

Place of Origin:

-

Jiangsu, China

-

Product name:

-

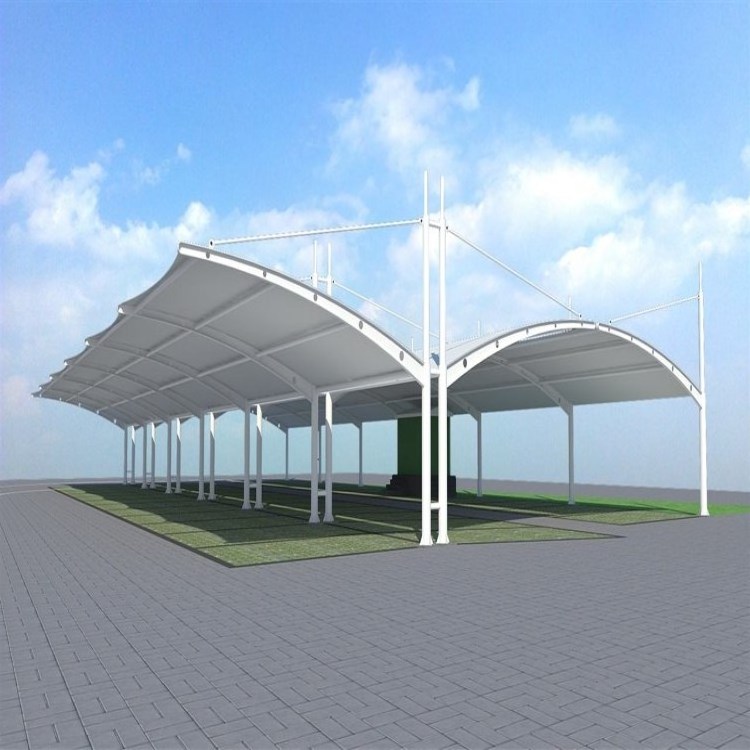

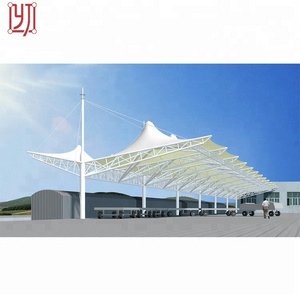

Steel truss frame structure design car parking shed canopy

-

Other Name:

-

steel frame parking shed

-

Drawing design:

-

AutoCAD ; Tekla

-

Finish treatment:

-

Hot-dip Galvanization or Paint

-

Characteristic:

-

frame truss structure

-

Color:

-

Blue; Green; Darkgray; Client's Request

-

Material:

-

Q235/Q345 Low Carbon Steel

-

Warranty:

-

One Year

-

Steel frame durable years:

-

50 years

-

Delivery time:

-

Shipping in 45 days after payment

Steel truss frame structure design car parking shed canopy

Steel truss frame structure design car parking shed canopy

Steel truss frame structure design car parking shed canopy

PRODUCT DESCRIPTION

| Material | Mild Steel; Stainless Steel |

| Coating | Spray Painting; Galvanization;Powder Coated |

| Color | Blue; Green; Darkgray; Client's Request |

| Steel code | Q235-B; Q345-B; Stainless steel |

| Fabrication | Advanced Automatic Welding Machines |

| Quality control | GB/T19001-2000----ISO9001:2000 |

| Advantages |

1.Stable and Aesthetic

2.Structure is durable for 50years 3.Fast and easy to install 4.Extensive Applications: Storage, Warehouse, Exhibition Hall,Terminal Building, Stadium, Theater, Special-shaped Buildings, etc 5.High anti-rust performance 6.Flexible composition: Doors and Day-lighting roof could be installed at any position |

Ⅰ. Material grade

1.Carbon structural steel: Q235.

2.High-strength structural steel :Q345

3.Special purpose steel t

ⅡQuality standard

1.Certificate: ISO9001:2000

2.Code for design of steel structure: GB 50017-2003

3.Technical code of cold-formed thin-wall steel structure: GB50018-2002

4.Load code for the design of building structures. GB 50009-2006

5.Construction quality acceptance of steel: GB50205-2001

6.Code for design, construction and acceptance of high strength for steel structure, JGJ82-2011

7.Technical specification for welding of steel structure building: JGJ 81-2002

8.Technical specification for steel Structures of tall buildings: (JGJ99-98)

Ⅲ. Structure Assembly

1.Steel Framework:

Component: H-Column, H-Beam & C/Z-Purlin

Connection of steel structure method: Welding, Bolted

2.Surface treatment: Painting, Galvanized

3.Roof &Wall: colored steel tiles or colored steel sandwich panel as per

request

4.Doors: Rolling or Pushing, as request

V. Steel characteristics

1.Environmental protection

2.Higher reliability of steel work

3.Strong quakeproof

4.Higher degree of industrialization

5.Quick to be assembled accurately

6.Larger interior space

Our excellent design team will design the steel structure workshop warehouse for you. If you give the following information, we will give you an satisfactory drawing.

1 Location (where will be built? ) _____country, area

2 Size: Length*width*height _____mm*_____mm*_____mm

3 wind load (max. Wind speed) _____kn/m2, _____km/h, _____m/s

4 snow load (max. Snow height)

_____kn/m2, _____mm

5 anti-earthquake _____level

6 brickwall needed or not If yes, 1.2m high or 1.5m high

7 thermal insulation If yes, EPS, fiberglass wool, rockwool, PU sandwich panels will be suggested; If not, the metal steel sheets will be ok. The cost of the latter will be much lower than that of the former.

8 door quantity & size _____units, _____(width)mm*_____(height)mm

9 window quanity & size _____units, _____(width)mm*_____(height)mm

10 crane needed or not If yes, _____units, max. Lifting weight____tons; Max. Lifting height _____m

PRODUCTION PROCESS