- Product Details

- {{item.text}}

Quick Details

-

Material:

-

it depends

-

Weight:

-

it depends

-

Size:

-

as request

-

Power:

-

0

-

Weight (KG):

-

5 kg

-

Product name:

-

sintered filter cartridge

-

Micron Rate:

-

0.1 to 300 micron

-

Porous plastics:

-

PE, HDPE, PA, PTFE, Nylon, PVDF etc

-

Porous metal filter:

-

Titanium, SUS304/316, bronze, etc

-

Interface form:

-

222,226,215, M36, M24, M22, M20 thread interface

-

Length:

-

OEM, 5", 10", 20", 30", 40", 50'', 60''

-

Layers:

-

1 to 5 layers

-

Usage:

-

gas, liquid filtration

-

Dimension:

-

customized solution

-

Working pressure:

-

0.1 to 30Mpa

Quick Details

-

Core Components:

-

filter element

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Lvyuan / OEM

-

Material:

-

it depends

-

Weight:

-

it depends

-

Size:

-

as request

-

Power:

-

0

-

Weight (KG):

-

5 kg

-

Product name:

-

sintered filter cartridge

-

Micron Rate:

-

0.1 to 300 micron

-

Porous plastics:

-

PE, HDPE, PA, PTFE, Nylon, PVDF etc

-

Porous metal filter:

-

Titanium, SUS304/316, bronze, etc

-

Interface form:

-

222,226,215, M36, M24, M22, M20 thread interface

-

Length:

-

OEM, 5", 10", 20", 30", 40", 50'', 60''

-

Layers:

-

1 to 5 layers

-

Usage:

-

gas, liquid filtration

-

Dimension:

-

customized solution

-

Working pressure:

-

0.1 to 30Mpa

Sintered Porous Plastic Products:

Guangzhou Lvyuan Filter produces wide range of sintered porous plastic products, including porous PE/HDPE tubes (filters), porous PTFE tubes (filters), porous filtration sheets, self sealing valve cartridges, and other porous material PA, PVDF, Nylon, and more.

We can produce polypropylene, polyethylene, PTFE, PVDF, PA and other polymer micro porous products with various shapes and complete specifications, which can meet the requirements of different customers.

Porous Plastics Products Applications:

1. Environmental protection

2. Automobile,

3. medical treatment,

4. chemical engineering,

5. water treatment, water purification filter system, waste water treatment equipment,

7. syrup and grease filter system,

8. acid-proof slices for automobile battery,

9. anti-explosion slices for industrial battery,

10. blind plug for medical treatment,

11. drunk driving tester,

12. oil water separator and silencer.

Porous Plastics Products Specifications:

|

Dimensions

|

|

|

|

Regular size (mm)

|

31x12x1000, 31x20x1000, 38x20x1000, 38x18x1000, 38x20x1200, 38x20x1300, 38x20x150, 38x20x400, 38x20x250, 38x20x200, 38x20x180, 38x20x150, 50x20x1000, 50x31x1000, 50x38x1000, 65x31x1000, 65x38x1000, 64x44x1000, 78x62x750mm, etc. for PE material as reference.

|

|

|

Other dimensions/Shapes

|

Customized by customer's request.

|

|

|

Material of constructions

|

|

|

|

Filter media option

|

PE, HDPE, PTFE, PVDF, PA/Nylon etc

|

|

|

Connector type

|

DOE/SOE, Flat, Insert type, Thread type, Fin

|

|

|

End caps

|

PP, M36, M30, M25, M22, M14, M12, or as request.

|

|

|

Shapes

|

tube/pipe, sheets, pleated type or as your drawing

|

|

|

Performance

|

|

|

|

Pore size / Removal rate

|

0.3, 0.45, 1, 3, 5, 10,20, 30, 40, 50um or as request

|

|

|

Maximum Operating Temperature

|

≦82℃ (based on Porous PE products)

|

|

|

Maximum Operating Pressure

|

6.0bar

|

|

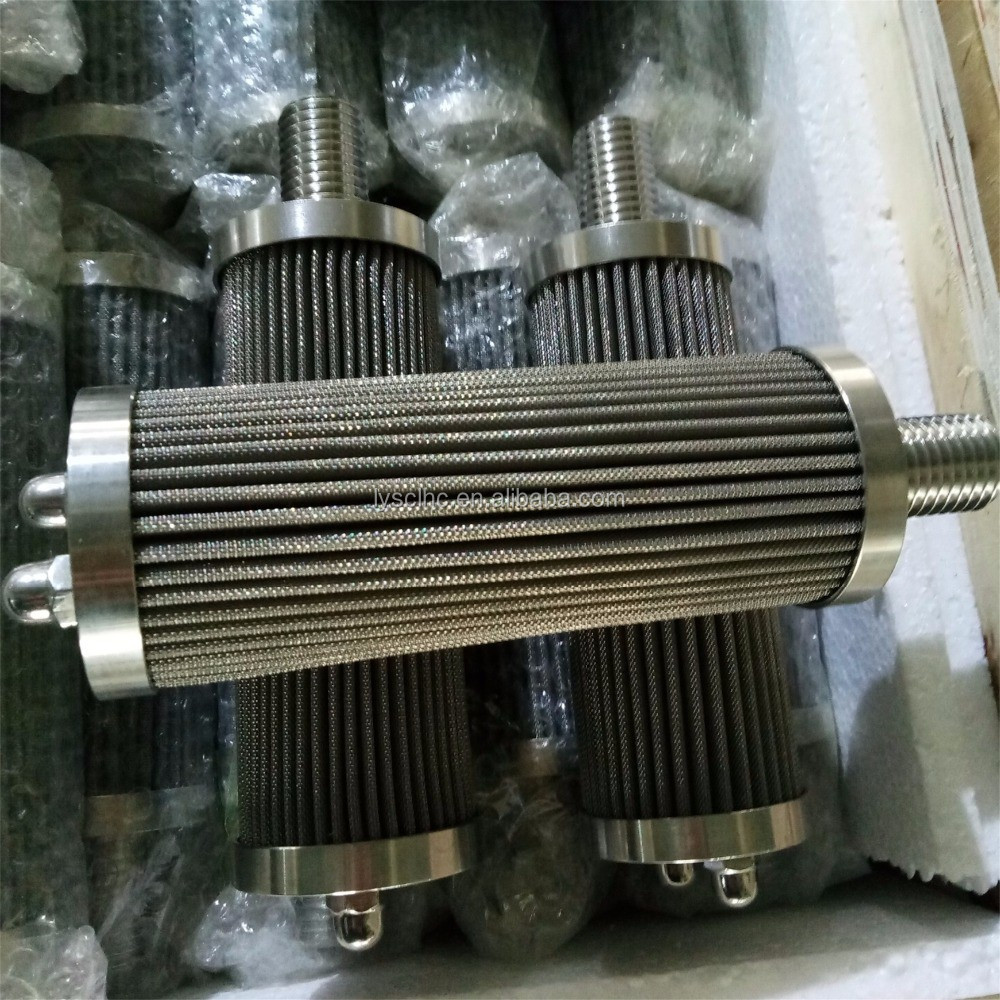

Plain cylindrical design stainless steel wire mesh filter cartridge

Pleated configuration design SS folded mesh filter cartridge

SS316L stainless steel porous powder sintered filter cartridge

Sintered Stainless Steel Porous Filter Cartridge:

Sintered Stainless Steel Filter Cartridges are the perfect choice for high temperature, high differential pressure and high viscosity applications. Manufactured with 304, 316 or 316L material, Stainless steel filter element can get a large filtration area and with high flow rate. It extends cartridge life and have more dirt holding capacity. Moreover, The stainless steel/SS filter cartridges are designed for cleanable and reusable applications thereby eliminating frequent cartridge change out, so it can significantly reduce disposal cost.

Non-standard Stainless steel filter cartridges can be easily customized with various dimension, end cap, outer cage pattern etc. So as long as customer give us the picture and drawing of the ss filter cartridge, we can custom-make the exact ss filter element to you.

Sintered Stainless Steel Porous Filter Cartridge Application:

1.Water filtrations

2. Hydraulics and Pneumatics

3. Automotive

4. Chemical filtrations

5. Petrochemical, oil & gas filtration

6. Pharmaceutical and Medical

7. Aeronautical

8. Mining

9. Food & beverage

Sintered Stainless Steel Porous Filter Cartridge Specification:

|

Dimensions

|

|

|

|

Length

|

5'' (125mm), 10'' (250mm), 20'' (500mm), 30'' (750mm), 40'' (1000mm)

|

|

|

Diameter

|

Ø25, 30, 50, 60, 65, 70mm or as request

|

|

|

Other dimensions

|

Can be Customized by customer's request.

|

|

|

Material of constructions

|

|

|

|

Filter media

|

SUS304, 316, 316L stainless steel

|

|

|

Connector type

|

Flat, Insert type, Thread type, Fin

|

|

|

End caps

|

DOE, SOE, 215, 222, 226, M20, M30, M42, 1'' NPT/BSP or as request.

|

|

|

External protection net

|

Optional

|

|

|

Sealing material

|

Silicone, NBR, EPDM, Buna, Teflon, etc

|

|

|

Performance

|

|

|

|

Pore size /Filtration rate

|

1, 3, 5, 10,20, 30, 40, 50, 100um or as request

|

|

|

Operation Temperature

|

≦480℃

|

|

|

Maximum Operating Pressure differential

|

4.0 bar

|

|

|

Cleaning method

|

back flushing, ultrasonic or other non-abrasive cleaning

|

|

Sintered Porous Titanium Filter Cartridges:

Porous Titanium metal powder filter cartridge is made by titanium metal powder which purity is above 99.6%. Titanium powder is sintered to form a rugged, fixed pore structure, Titanium filter cartridges are made to withstand temperature extremes, high pressures and repeated cleaning/backwash cycles. There are no longitudinal seams, for improved mechanical strength and corrosion resistance.

Sintered titanium filter cartridges are produced in a range of configurations (DOE, screw type) and micron ratings to perform in a variety of liquid and gas applications. It supply broad chemical compatibility and is widely used in food & beverage, pharmaceutical and chemical industry, especially for decarbonizing filtration.

Sintered Porous Titanium Water Filter Cartridge Specification:

|

Dimensions

|

|

|

|

Length

|

5'' (125mm), 10'' (250mm), 20'' (500mm), 30'' (750mm), 40'' (1000mm)

|

|

|

Diameter

|

Ø22, 30, 50, 60, 70, 80, 100, 120mm

|

|

|

Other dimensions

|

Customized by customer's request.

|

|

|

Material of constructions

|

|

|

|

Filter media

|

Titanium

|

|

|

Connector type

|

Flat, Insert type, Thread type, Fin

|

|

|

End caps

|

DOE, 215, 222, 226, M20, M30, M42 or as request.

|

|

|

Sealing material

|

Silicone, NBR, EPDM, Fluoro rubber, etc

|

|

|

Performance

|

|

|

|

Removal rate

|

0.1, 0.45, 1, 3, 5, 10,20, 30, 40, 50, 100um

|

|

|

Temperature Tolerance

|

≦300℃ wet

|

|

|

Permeability

|

0.02-20L/cm2 min Pa

|

|

|

Maximum Operating Pressure differential

|

6.0bar

|

|

|

Flow rate (L/H)

|

180, 200, 250, 280, 300, 350, 500, 800, 1000, 1500, 1600

|

|

|

Micron rate (μm)

|

0.2

|

0.45

|

1

|

2

|

3

|

5

|

10

|

20

|

30

|

|

Flow rate (L/H)

|

180

|

200

|

250

|

280

|

300

|

350

|

500

|

800

|

1000

|

Sintered Activated Carbon Filter Cartridges:

LVYUAN can custom-make industry-standard sized sintered carbon blocks Filter Element to suit the requirements of OEMs worldwide.

We use the world's advanced technology of sintering molding and SGS compliant raw materials and the finest grades of activated carbon to make CTO carbon block filter cartridges. Sintered CTO carbon block filter cartridges have strong adsorption ability and good rigid structure.

Sintered carbon block filter can remove chlrine, bad taste and odor, choramines, fine sediment, organic chemicals with high filtration efficiency. It can deliver superior performance to a variety of water and gas purification applications.

Sintered Activated Carbon Block Filter Cartridge Specification:

|

Dimensions

|

|

|

|

Outer diameter

|

14, 16, 19, 25, 28, 30, 35, 38, 40, 45, 46, 50, 53, 55, 60, 63, 64, 67, 70, 76, 90, 96.5, 103, 105, 121mm

|

|

|

Inner diameter

|

6, 8, 10, 12, 14, 16, 18, 20, 22, 25, 28, 30, 32, 35, 38, 40, 45, 50mm

|

|

|

Length

|

5'' (125mm), 10'' (250mm), 20'' (500mm), 30'' (750mm), 40'' (1000mm)

|

|

|

Other dimensions

|

Customized by customer's request.

|

|

|

Material of constructions

|

|

|

|

Filter media

|

Coconut shell carbon, coal carbon

|

|

|

Enc caps

|

Polypropylene

|

|

|

Netting

|

Polypropylene

|

|

|

Gasket/oring material

|

Silicone, EPDM, NBR, Viton

|

|

|

Performance

|

|

|

|

Removal rate

|

5, 10, 25 um

|

|

|

Maximum Operating Temperature

|

≦80℃

|

|

|

Maximum Operating Pressure

|

17 bar

|

|

|

Maximum differential pressure

|

7 bar at 25℃

|

|

Factory

Workshop

Our Workshop

Warehouse

Our Warehouse

Team

Our Team