- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Stainless Steel SUS304/316L

-

Application:

-

Wide ranges

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Type:

-

Automatic self clraning filter housing

-

Certificate:

-

ISO9001:2008, CE

-

Material:

-

Stainless Steel SUS304/316L

-

Application:

-

Wide ranges

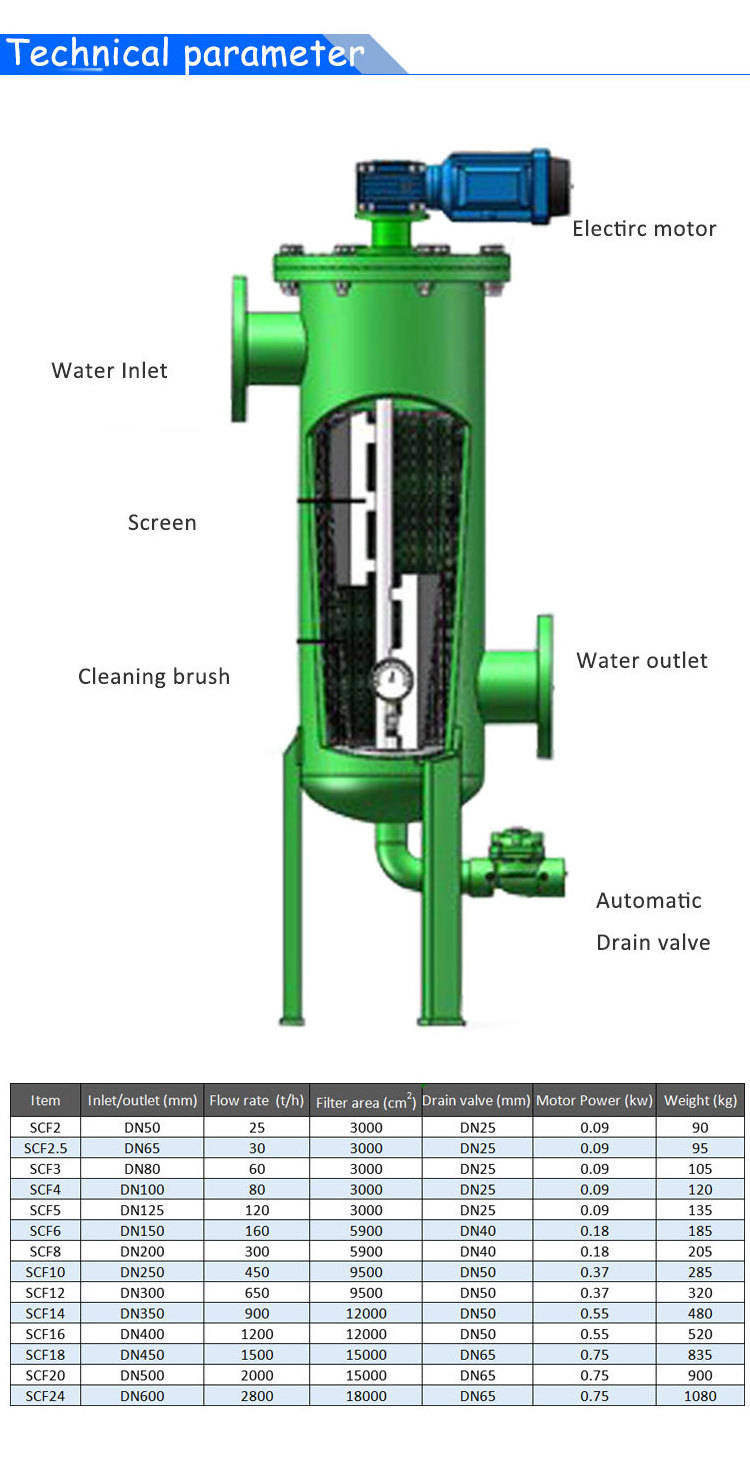

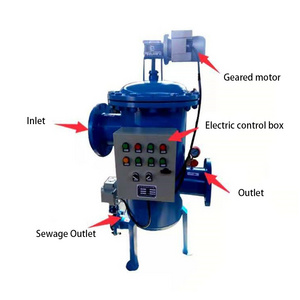

Filtration – functional principle:

The filtration happens from inside to outside through the filter basket. There is collection of particles on the smooth inner side of the filter basket. Then, as the level of contamination increases, the differential pressure between the contaminated and clean sides of the filter increases.

Moreover, when the pressure drop reaches the pre-set trigger point, filter basket cleaning starts automatically. When we reach the differential pressure trigger point, then the gear motor turns past the rinsing unit positioned on the inside of the filter basket.

Back-flushing – functional principle:

The pressure drop between the filtrate and back-flush line leads to effective cleaning of the filter mesh. Therefore, a flushing device optimised for flow and adjusted to suit the filter basket provides a particularly effective cleaning of the filter material. What’s more, it manages to overcome the adhesion forces of silt particles, or organisms caught in the ballast water, even in the case of ultrafine filtration.