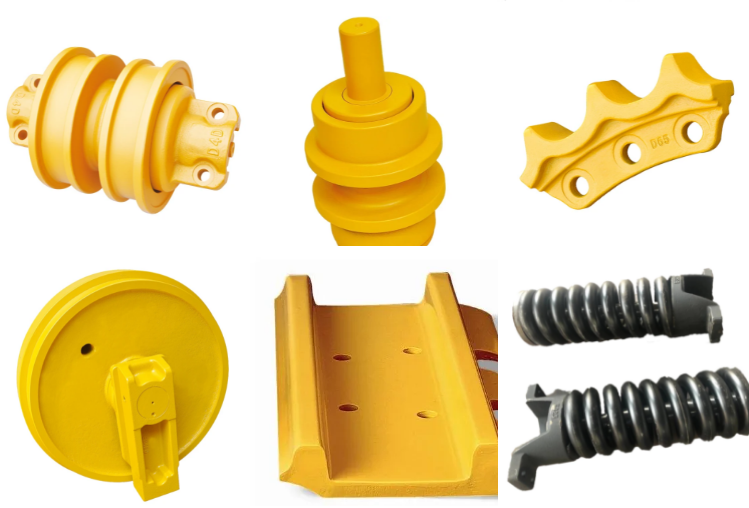

- Product Details

- {{item.text}}

Quick Details

-

Surface hardness:

-

HRC42-50 track shoes ass'y

-

Colour:

-

Black,yellow,or others

-

processing:

-

forging casting track shoes ass'y

-

Certification:

-

ISO14001/GB/T

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

DZR

-

Material:

-

35Mnb,40mn2,40CR track shoes ass'y

-

Surface hardness:

-

HRC42-50 track shoes ass'y

-

Colour:

-

Black,yellow,or others

-

processing:

-

forging casting track shoes ass'y

-

Certification:

-

ISO14001/GB/T

|

Material

|

35MnB/40Mn/40SiMnTi

|

|

Finish

|

Smooth

|

|

Colors

|

Black or yellow

|

|

Technique

|

Forging casting

|

|

Surface Hardness

|

HRC37-49

|

|

Pitch

|

135mm

|

|

Warranty time

|

2000 hour

|

|

Certification

|

ISO9001-9002

|

|

MOQ

|

10 piece

|

|

FOB Price

|

FOB Xiamen USD 10-40/Piece

|

|

Delivery Time

|

Within 20 days after contract established

|

Our Advantages:

2.Forging advantages: medium frequency heating, infrared temperature control, to ensure that the material evenly heated; The size is

consistent, the density is good, the two sides of the chain and the position of the bolt are not need to process;

3.Heat treatment process: residual heat quenching;

4.Heat treatment advantage: when forging out, the blank temperature control quenching, uniform cooling; Not easy to crack;

5.Medium frequency rail surface advantage: double quenching, quenching effective deep, can reach more than 10 mm; Complete annealing and flaw detection process and hardness on the same equipment;

Our Advantages:

6.Machining advantages: once clamping, direct forming; Product size is consistent, high precision;

7.Assembly advantages: accurate positioning, pressure control, we use imported sealing ring gasket, to ensure that the product will not enter the process of use;

8.Product model: The company from 90 to 260 pitch products are complete;

9.Link advantage: internal and external quenching products, high internal and external hardness, good deep. Increase the wear resistance of the product.

Hot Searches