- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Hot sale 2023

-

Name:

-

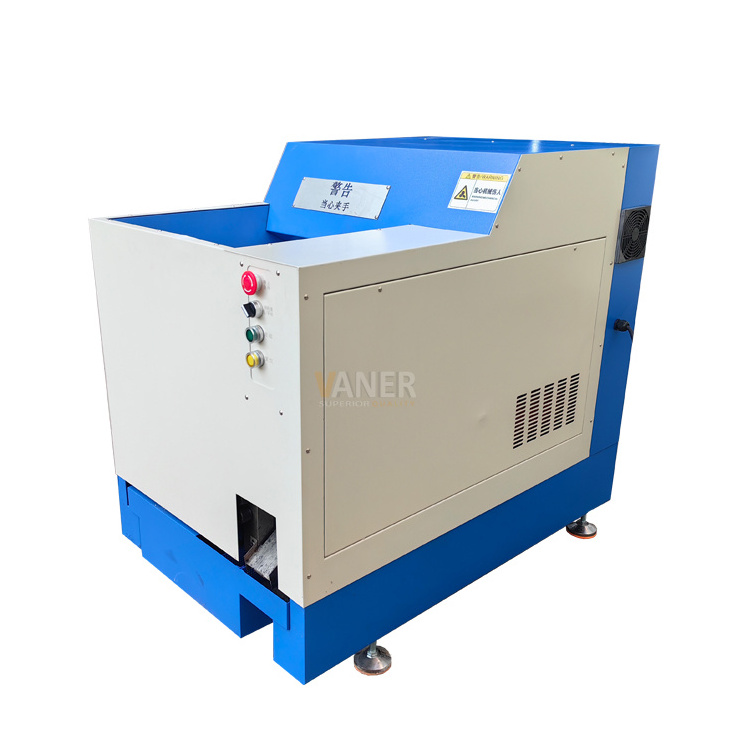

Aluminum Copper Powder Chips Hydraulic Briquetting Pressing Machine

-

Model:

-

V-XB420

-

Feed port capacity:

-

50L

-

Cut powder pressing method:

-

spiral

-

Powder Compression Method:

-

cylinder

-

Compressed size:

-

70,10-50MM

-

compression face pressure:

-

1080 KGF/CM

-

maximum pressure:

-

42 Tons

-

Applicable material:

-

Aluminum/stainless steel plate/iron/copper

-

Applicable cutting powder type:

-

Lathe/CNC/Saw

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

VANER

-

Weight (KG):

-

560

-

Marketing Type:

-

Hot sale 2023

-

Name:

-

Aluminum Copper Powder Chips Hydraulic Briquetting Pressing Machine

-

Model:

-

V-XB420

-

Feed port capacity:

-

50L

-

Cut powder pressing method:

-

spiral

-

Powder Compression Method:

-

cylinder

-

Compressed size:

-

70,10-50MM

-

compression face pressure:

-

1080 KGF/CM

-

maximum pressure:

-

42 Tons

-

Applicable material:

-

Aluminum/stainless steel plate/iron/copper

-

Applicable cutting powder type:

-

Lathe/CNC/Saw

Product Description

The product can compress the copper scraps, aluminum scraps, stainless steel scraps and other scraps produced by hardware processing into a single round cake of 70mm in diameter.

FUNCTOION

To save the workshop warehouse storage space, as well as the space of the scrap transport vehicle box, but also to facilitate the handling, save labor time. And the selling price of scrap can generally be increased by about 15% to 30%.

The cutting oil can be recovered automatically while pressing the cake, and the regeneration rate is more than 95%. Therefore, the user can recover the investment in equipment in about three months after purchasing the machine.

Product Specification

|

Dimensions

|

W700*D1100*H930

|

|

Hopper inlet size

|

520*450MM

|

|

Hopper inlet height

|

780MM

|

|

Feed port capacity

|

50L

|

|

Oil port capacity

|

18L

|

|

Cut powder pressing method

|

spiral

|

|

Powder Compression Method

|

cylinder

|

|

Compressed size

|

∅70,10-50MM

|

|

compression face pressure

|

1080 KGF/CM

|

|

Maximum pressure

|

42 Tons

|

|

Applicable material

|

Aluminum/stainless steel plate/iron/copper

|

|

Applicable cutting powder type

|

Lathe/CNC/Saw

|

|

Cut powder compression volume ratio

|

Lathe cutting powder 20:1

|

|

Cutting powder compression volume ratio

|

CNC/saw cutting powder 5:1

|

|

Cycle Time

|

Approx. 24 seconds

(excluding the time taken to engage compression) |

|

Weight

|

560 KG

|

|

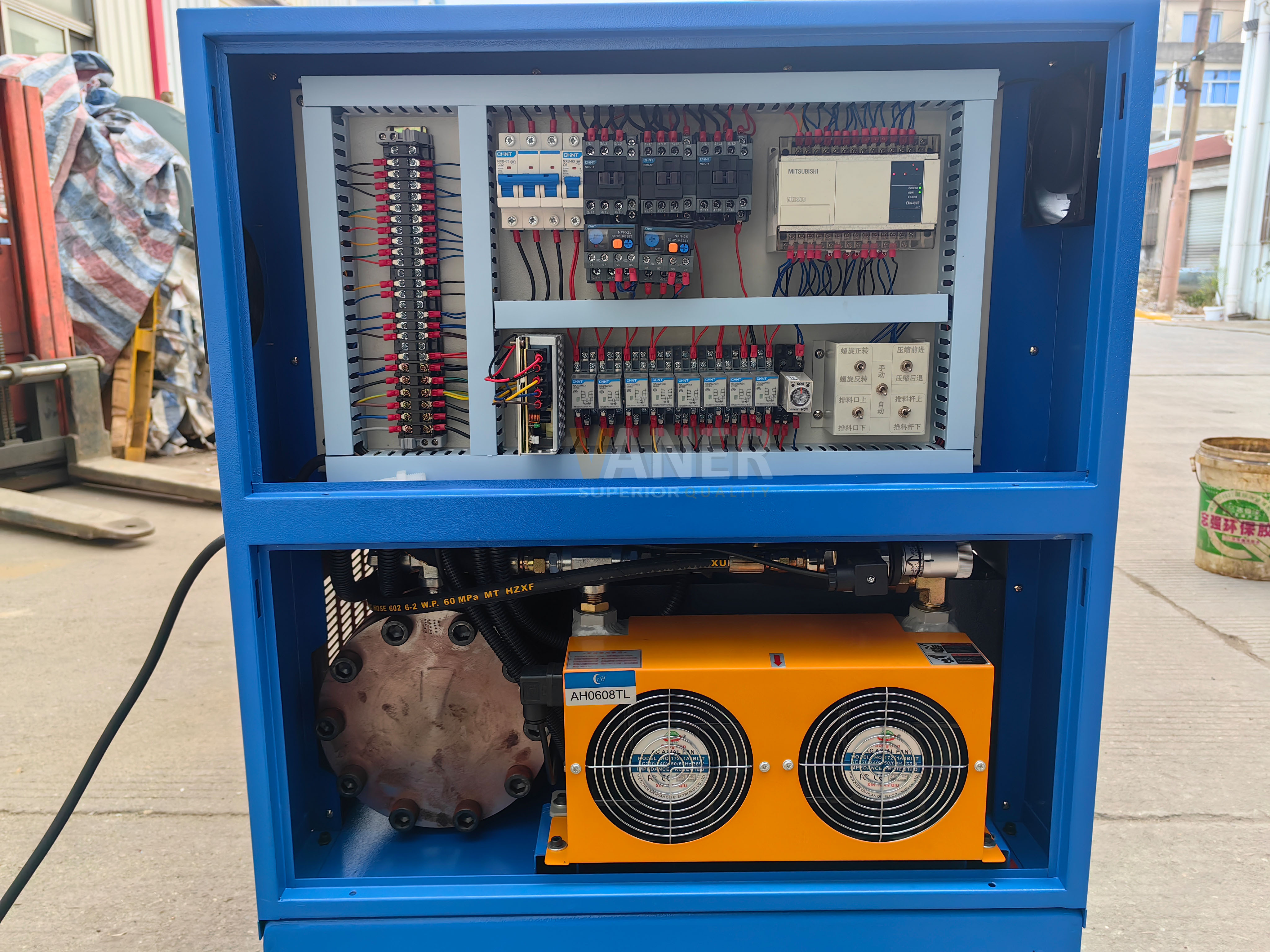

Power supply

|

Three-phase 380 V

|

|

Power

|

3 KW

|

Advantage

1.The basic specifications of the equipment parameters: 1.1 meters long / 0.7 meters wide / 0.9 meters high, power consumption of 1.5 degrees / hour. One minute can be pressed 2 cakes. Pressing copper cake about 90-120 kg / hour, pressed aluminum cake about 1-2 kg / hour. The machine is equipped with a screen to control the feeding speed of the machine.

2. For the recycling of cutting oil, the oil is squeezed into the container while pressing the cake, and the recovery rate reaches 95%. When the cutting is compressed, most of the cutting fluid will be squeezed out and collected into the oil tank, there is a level gauge in the oil tank, when the level gauge is triggered, the oil pump will pump out the oil in the oil sump. Even if a small amount of cutting fluid is discharged from the discharge port, it will be recovered from the guide port of the swash plate to the oil sump.

3. The storage space savings a. The compression ratio of CNC bed waste is 5:1, and the compression ratio of lathe waste is 20:1, which greatly saves the use area of the workshop warehouse occupied by the waste. b. Also save the space of scrap transportation box, one trip can load more scrap.

4. The labor time saving a. The press cake machine can be put together with the workshop processing equipment nearby, clean up the machine tool scrap into the hopper by hand, in the work gap can be completed press cake work (some customers factory with full-time scrap processing workers) comprehensive calculation, the use of the machine, the scrap from the workshop clean up and then put into the scrap warehouse, plus the immediate recovery of cutting oil to save labor time, compared to the previous not use the press cake machine can save a lot of labor time. b. The labor time required for loading and unloading scrap when collecting and selling scrap is also greatly reduced.

5. The price of scrap sold after pressed into cakes can be increased by about 15%~30%, and the workshop warehouse is more clean and beautiful after using the machine. Clean and beautiful, enhance the company's clean image, while contributing to environmental protection.

6. The key components of the cake press machine are imported brands, quality assurance, reliable and durable. The company's patented products, their own R & D production and sales, sincere service to customer satisfaction and peace of mind. More than 30 square meters for placing waste area.

Shipping and Package

* Packing the machine with wooden box, or delivery with Container without packing, to prevent them from destroying during transportation.

* We will choose the most convenient and economic way to delivey goods for you.

* If you have specific demand with delivey, we can make it.

* We will choose the most convenient and economic way to delivey goods for you.

* If you have specific demand with delivey, we can make it.

Customer Feedback

Certifications

About Us

VANER 3D VR Show Room Display

One-Stop Solution Provider For Recycling Business

please click the picture to enter VR showroom

Vaner Machinery

Co.,Ltd is a professional solution provider that provides environmental protection machinery design, development, manufacturing, sales and service for enterprises since 1995.After more than 25 years developing,we have 18000 square workshop, 100 employees,20 Technicians,4% R & D expenditure,50 mechanical processing equipment, passed the CE international certification ,more than 20 kinds of products have own patent of invention and utility model .

Contact Us

If You Have Any Needs, Please Feel Free To Contact Us!

Click "Send"

Hot Searches