- Product Details

- {{item.text}}

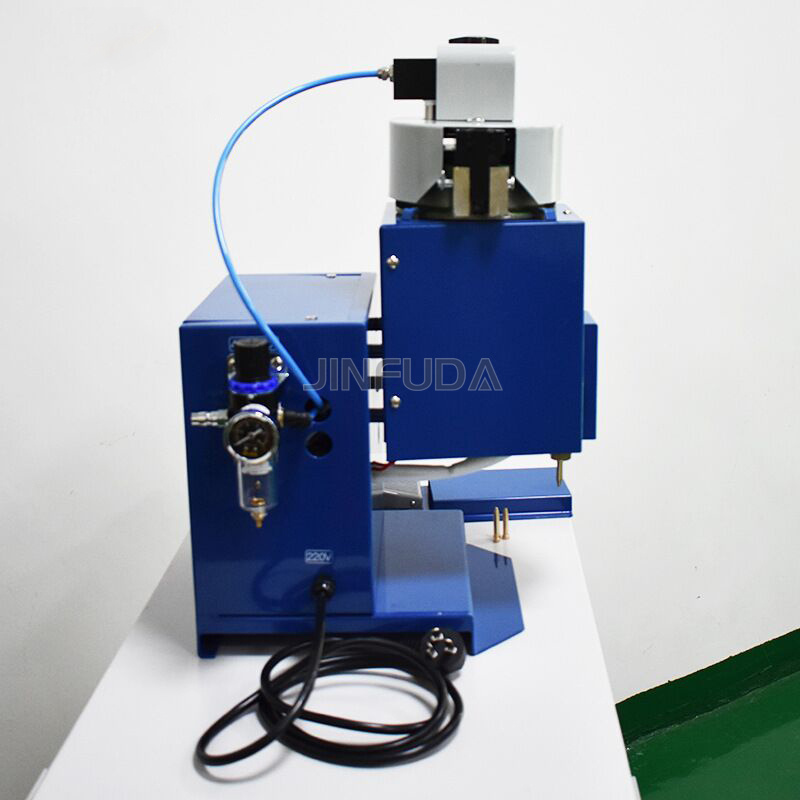

Quick Details

-

Dimension(L*W*H):

-

400*400*550MM

-

Weight:

-

14 KG

-

Feeding way:

-

Hand Feeding

-

Heating tank capacity(L):

-

1.0

-

Melting rate(Kg/hr):

-

2.5

-

Air pressure(Kg/cm2):

-

max.4.0

-

Electricity demand:

-

220V, 50/60Hz

Quick Details

-

Voltage:

-

220V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

JINFUDA

-

Dimension(L*W*H):

-

400*400*550MM

-

Weight:

-

14 KG

-

Feeding way:

-

Hand Feeding

-

Heating tank capacity(L):

-

1.0

-

Melting rate(Kg/hr):

-

2.5

-

Air pressure(Kg/cm2):

-

max.4.0

-

Electricity demand:

-

220V, 50/60Hz

Product Description

Hot melt glue machine are widely used in sanitary products (diapers, sanitary napkins ), air filter, non-woven composite, footwear, printing, product assembly, clothing, stickers, packaging industry (carton packaging, cigarette cases, wine Boxes, Gift Boxes, Glasses Cases, Craft Boxes, Jewelry Boxes, Color Boxes, , Coated Composites (trademark papers, labels, double-sided tapes, medical breathable tapes), Product Assemblies (Home Appliances, Furniture fittings, wire and cable) automotive industry (interior seals, headlight manufacturing, windshield assembly) book binding field and other industries.

1. Rubber groove switch adopts buckle cup design, easy to open canning handle, easy to operate.

2. Pneumatic power system

3. Simple structure and easy maintenance. It can be maintained by itself only in accordance with the use and maintenance instructions in the manual. Pressure and flow can be adjusted. The spray flow can be controlled freely through the air pressure and the stroke of the nozzle. The melt rate is fast. 850W power plus high efficiency insulation device. Save energy, improve melting speed.

4. Low failure rate. The structure is clear, and the minimum system connection is implemented in each part of the components.

5. Wide operating temperature range. The operating temperature is 20°C-250°C

6. The timer can control the amount of glue spraying each time, and can choose a variety of time control for 0-3 seconds.

7. The needle valve controls the instant closing of glue. Using gas open spring close mode, switch sensitive.

8. Improve product performance and grade. Compared with the ordinary hot melt glue gun, make the product bonding more firm, high efficiency.

9. Increase efficiency and reduce waste. No need to wait after melting glue, ready to use. No glue, no leakage, reduce waste.

10. Wide range of application, from the type of hot melt adhesive, shape, viscosity, melting temperature, spraying method and other restrictions.

Hot melt glue machine are widely used in sanitary products (diapers, sanitary napkins ), air filter, non-woven composite, footwear, printing, product assembly, clothing, stickers, packaging industry (carton packaging, cigarette cases, wine Boxes, Gift Boxes, Glasses Cases, Craft Boxes, Jewelry Boxes, Color Boxes, , Coated Composites (trademark papers, labels, double-sided tapes, medical breathable tapes), Product Assemblies (Home Appliances, Furniture fittings, wire and cable) automotive industry (interior seals, headlight manufacturing, windshield assembly) book binding field and other industries.

1. Rubber groove switch adopts buckle cup design, easy to open canning handle, easy to operate.

2. Pneumatic power system

3. Simple structure and easy maintenance. It can be maintained by itself only in accordance with the use and maintenance instructions in the manual. Pressure and flow can be adjusted. The spray flow can be controlled freely through the air pressure and the stroke of the nozzle. The melt rate is fast. 850W power plus high efficiency insulation device. Save energy, improve melting speed.

4. Low failure rate. The structure is clear, and the minimum system connection is implemented in each part of the components.

5. Wide operating temperature range. The operating temperature is 20°C-250°C

6. The timer can control the amount of glue spraying each time, and can choose a variety of time control for 0-3 seconds.

7. The needle valve controls the instant closing of glue. Using gas open spring close mode, switch sensitive.

8. Improve product performance and grade. Compared with the ordinary hot melt glue gun, make the product bonding more firm, high efficiency.

9. Increase efficiency and reduce waste. No need to wait after melting glue, ready to use. No glue, no leakage, reduce waste.

10. Wide range of application, from the type of hot melt adhesive, shape, viscosity, melting temperature, spraying method and other restrictions.

|

Model

|

JFD-102A

|

JFD-103A

|

|

Heating tank capacity(L)

|

1.0

|

1.0

|

|

Melting rate(Kg/hr)

|

2.5

|

2.5

|

|

Operating temperature(℃)

|

max.250

|

max.250

|

|

Air pressure(Kg/cm2)

|

max.4.0

|

max.4.0

|

|

Adhesive type

|

Dots, stripes

|

Fog, dots, stripes

|

|

Electricity demand

|

220V, 50/60Hz

|

220V, 50/60Hz

|

|

Weight(Kg)

|

14

|

14

|

|

Power(W)

|

800

|

800

|

|

Using viscosity(Cp.s)

|

max. 500-20000

|

max. 500-20000

|

Hot Searches