- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

LUK

-

Product Name:

-

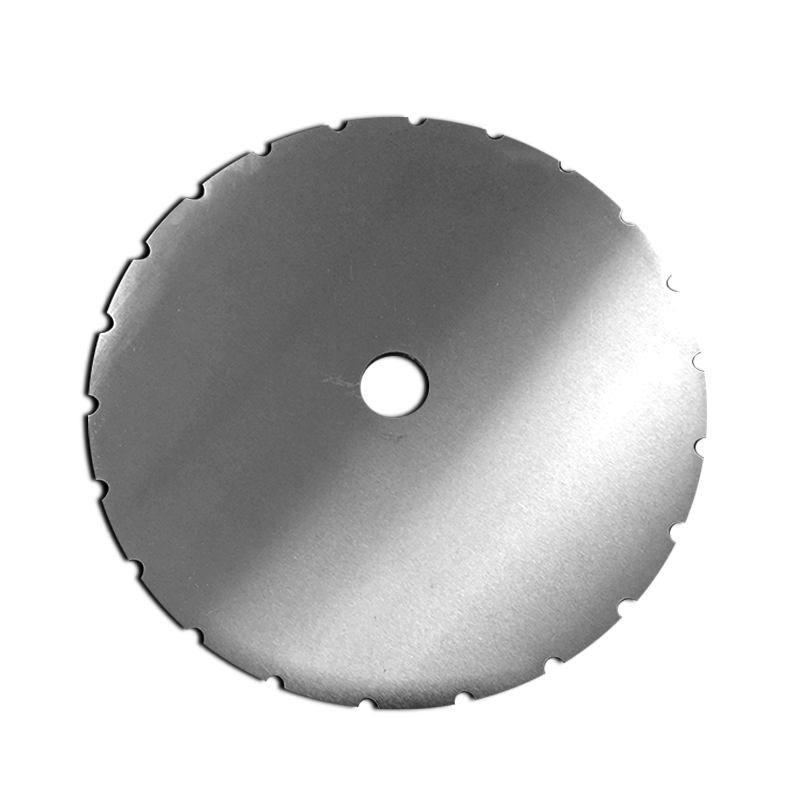

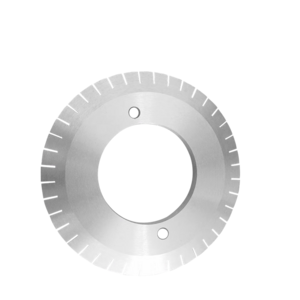

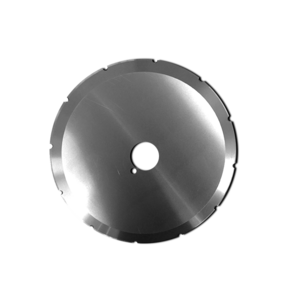

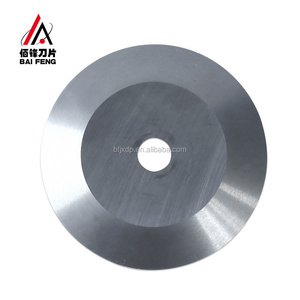

BAADER PISCES Fish Cutting Round BladeFish De-heading Machine Blade

-

Size:

-

200 mm

-

Material:

-

Stainless Steel 440

-

Hardness:

-

54-58 HRC

-

OEM service:

-

Available

-

MOQ:

-

50 pcs

-

Main market:

-

Europe, North America, Ocenia etc

-

Packing:

-

Simple packing/Plastic box packing/Blister packing

Quick Details

-

Weight (KG):

-

2

-

Marketing Type:

-

New Product

-

Place of Origin:

-

Guangxi, China (Mainland)

-

Brand Name:

-

LUK

-

Product Name:

-

BAADER PISCES Fish Cutting Round BladeFish De-heading Machine Blade

-

Size:

-

200 mm

-

Material:

-

Stainless Steel 440

-

Hardness:

-

54-58 HRC

-

OEM service:

-

Available

-

MOQ:

-

50 pcs

-

Main market:

-

Europe, North America, Ocenia etc

-

Packing:

-

Simple packing/Plastic box packing/Blister packing

Welcome to LUK knives. We are a professional manufacturer in food industry blades and knives. Fish cutting blades are our main products. They are made of best stainless steel, with sharp cutting edge and long life. Standard blades for

BAADER,PISCES, VMK .... and customerized blades are all available. Your inquiry will be replied at once.

220mm BAADER PISCES Fish Cutting Slicing Filleting machine blades knife meat circular saw Messer

Product Description

|

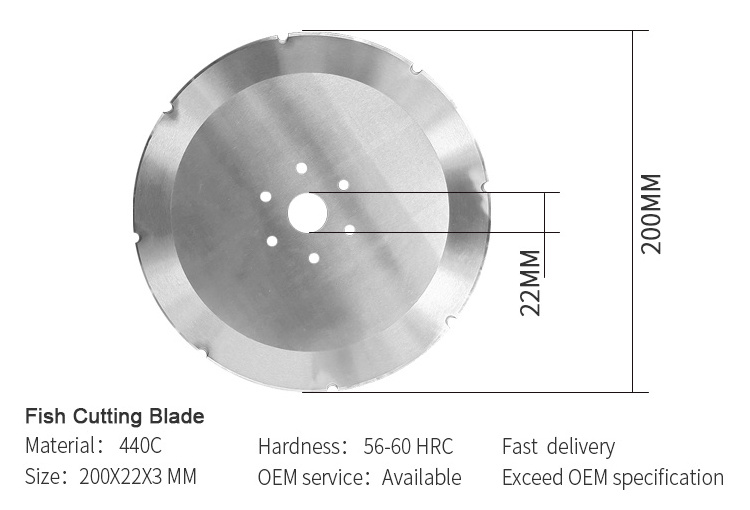

Specification

|

|

|

|

Size

|

220x22x3 mm or customized size

|

|

|

Material

|

Stainless Steel 420/440c

|

|

|

Flatness

|

< 0.1 mm

|

|

|

Surface Treatment

|

Mirror grinding

|

|

|

Hardness

|

54-60 HRC

|

|

|

OEM Service

|

Available

|

|

|

Certification

|

TÜV, SGS

|

|

|

Website

|

http://www.luk-knife.com

|

|

Related Products

Quality Assurance

Packing&Shipping

Company Introduction

FAQ

Q: What Steel Grades do you use to manufacture Industrial Blades?

A: We select appropriate Steel Grades for your applications. Popular materials for example:

Food processing blades – Stainless steel 420, 440A and 440C.

Plastic recycling blades and wood-working blades – D2/SKD11, DC53, A8, etc.

Paper making, printing and slitting blades – Steel 52100, D2/SKD11, SS, HSS (High Speed Steel) and Tungsten Carbide.

Q: How long do your machine knives work before re-sharpening?

A: Up to 50% longer than competitors according to feedbacks from our dear customers. Please contact us. Our expert team will assess your cutting requirements and working conditions to help you find the longer-life solution.

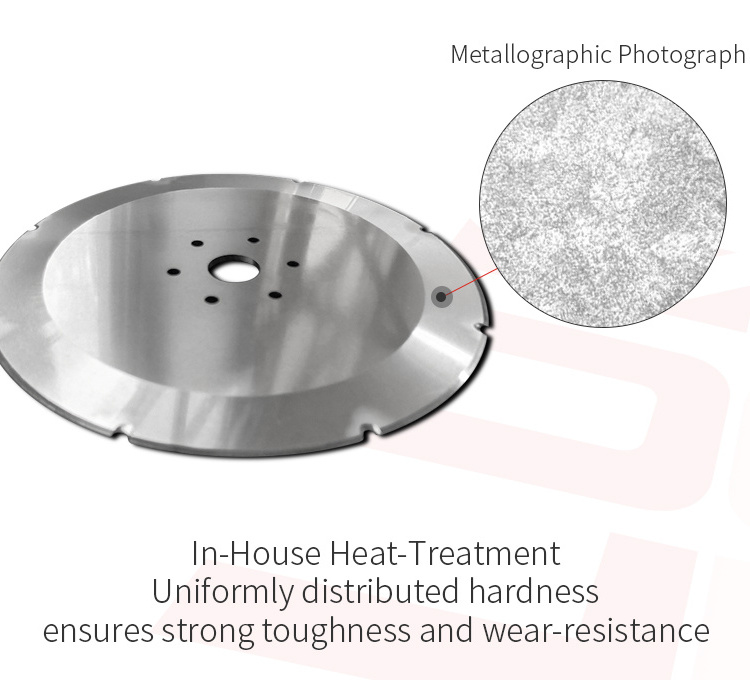

Q: How do you guarantee your quality?

A: All operations from original drawing to final product are strictly controlled and traceable . Never a defective product will be delivered to our customer.

Q: How long does it take to manufacture a machine knife to customized specification?

A: Normally 35 to 45 days. We can stock special knives for you. Please contact us to discuss your requirements.

Q: What is you payment terms?

A: Payment via Alibaba, TT, L/C are all acceptable.

A: We select appropriate Steel Grades for your applications. Popular materials for example:

Food processing blades – Stainless steel 420, 440A and 440C.

Plastic recycling blades and wood-working blades – D2/SKD11, DC53, A8, etc.

Paper making, printing and slitting blades – Steel 52100, D2/SKD11, SS, HSS (High Speed Steel) and Tungsten Carbide.

Q: How long do your machine knives work before re-sharpening?

A: Up to 50% longer than competitors according to feedbacks from our dear customers. Please contact us. Our expert team will assess your cutting requirements and working conditions to help you find the longer-life solution.

Q: How do you guarantee your quality?

A: All operations from original drawing to final product are strictly controlled and traceable . Never a defective product will be delivered to our customer.

Q: How long does it take to manufacture a machine knife to customized specification?

A: Normally 35 to 45 days. We can stock special knives for you. Please contact us to discuss your requirements.

Q: What is you payment terms?

A: Payment via Alibaba, TT, L/C are all acceptable.

Hot Searches