- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

5 mm

-

Width of Working Table (mm):

-

2000 mm

-

Dimension:

-

4500*1200mm*1300mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

WADJAY

-

Weight (KG):

-

1200

-

Motor Power (kw):

-

3 kw

-

Marketing Type:

-

Other

-

Product name:

-

Hydraulic Cnc Bending Machine

-

Max. Cutting Thickness (mm):

-

5 mm

-

Shearing Angle:

-

90°, 120°, 135°

-

Blade Length (mm):

-

15 mm

-

Backgauge Travel (mm:

-

2 - 30 mm

-

Power (kW):

-

3

-

Yield Strength:

-

G350

-

Bending Mold:

-

Cr12

-

Drive system:

-

Hydraulic

Quick Details

-

Machine Type:

-

Torsion Bar

-

Length of Working Table (mm):

-

Other

-

Slider Stroke (mm):

-

30 mm

-

Throat Depth (mm):

-

5 mm

-

Width of Working Table (mm):

-

2000 mm

-

Dimension:

-

4500*1200mm*1300mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

WADJAY

-

Weight (KG):

-

1200

-

Motor Power (kw):

-

3 kw

-

Marketing Type:

-

Other

-

Product name:

-

Hydraulic Cnc Bending Machine

-

Max. Cutting Thickness (mm):

-

5 mm

-

Shearing Angle:

-

90°, 120°, 135°

-

Blade Length (mm):

-

15 mm

-

Backgauge Travel (mm:

-

2 - 30 mm

-

Power (kW):

-

3

-

Yield Strength:

-

G350

-

Bending Mold:

-

Cr12

-

Drive system:

-

Hydraulic

Product Description

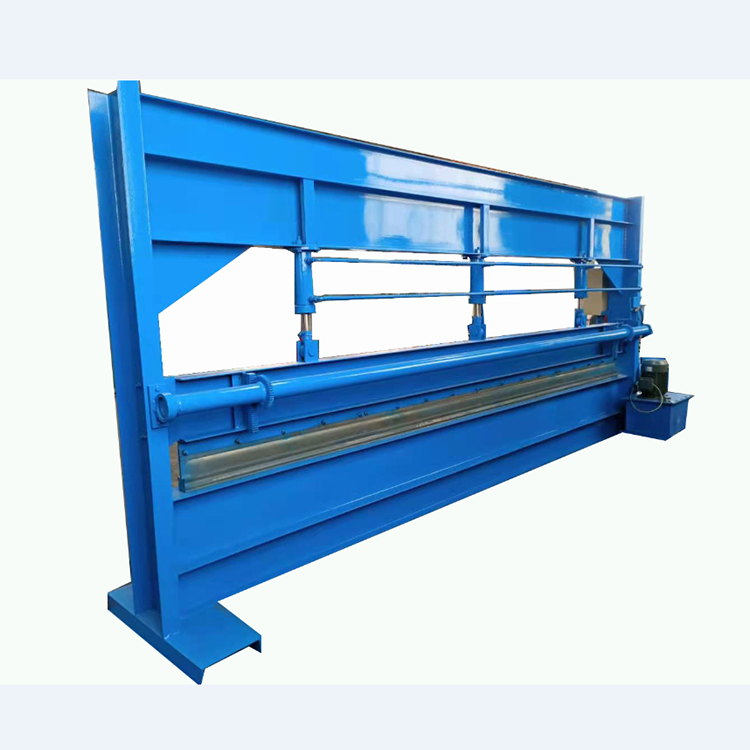

4m 6m Hydraulic Steel Aluminum Sheet Bending Machine

Instruction for Sheet Hydraulic Bending Machine Press Brake

a. This kind of machine is fit for below material: carbon steel, stainless steel, galvanized sheet, aluminum sheet and other kind of metal sheet.

b. The touch screen can control input, store and show various data and set orders.

c. Oil cylinder:2 or 4 oil cylinder, that is decided by the material, thickness.More larger thickness, the oil cylinder quantity is more bigger.

d. standard bending direction: clockwise bending(also can make anti-clockwise bending.)

b. The touch screen can control input, store and show various data and set orders.

c. Oil cylinder:2 or 4 oil cylinder, that is decided by the material, thickness.More larger thickness, the oil cylinder quantity is more bigger.

d. standard bending direction: clockwise bending(also can make anti-clockwise bending.)

Features for Sheet Hydraulic Bending Machine Press Brake

1. Adopt all-steel welded structure, with sufficient strength and rigidity;

2. Hydraulic drive, the oil cylinders at both ends of the machine tool are placed on the sliding block to directly drive the sliding work;

3. The slider synchronization mechanism adopts torsion shaft for forced synchronization;

4. Using mechanical block structure, stable and reliable;

5. The stroke of the slider can be adjusted quickly and manually, and the counter is displayed;

6. Oblique wedge-type deflection compensation mechanism to ensure higher bending accuracy.

Operating Procedures for Sheet Hydraulic Bending Machine Press Brake

1. First, turn on the power, turn on the key switch on the control panel, and then press the oil pump to start.

2. The stroke adjustment, the use of the bending machine must pay attention to the adjustment stroke, be sure to test run before bending. When the upper die of the bending machine descends to the bottom, there must be a gap of plate thickness. Otherwise it will cause damage to the mold and the machine. The stroke adjustment also has electric quick adjustment and manual fine adjustment.

3.Selection of bending notches

4. Backgauge adjustment generally includes electric quick adjustment and manual fine adjustment

5.Step on the foot switch to start bending. The bending machine is different from the shearing machine. You can release it at any time. When you release your foot, the bending machine will stop, and then step on to continue downward.

Specification

|

Type

|

Cutting Thickness(mm)

|

Cutting Width (mm)

|

Travel Times (times/min)

|

Cutting Angle ( ° )

|

Backgauge Range (mm)

|

Power(kw)

|

Dimension L*W*H(mm)

|

|

3*1200

|

3

|

1200

|

20

|

2 °25'

|

350

|

3

|

2015*1500*1300

|

|

3*1300

|

3

|

1300

|

20

|

2°25'

|

350

|

3

|

2115*1500*1300

|

|

3*1500

|

3

|

1500

|

20

|

2°25'

|

350

|

3

|

2515*1500*1300

|

|

4*2000

|

4

|

2000

|

20

|

1°30'

|

500

|

5.5

|

3200*1300*1610

|

|

4*2500

|

4

|

2500

|

20

|

1°30'

|

500

|

5.5

|

3580*1300*1610

|

|

4*3200

|

4

|

3200

|

20

|

1°30'

|

600

|

7.5

|

4380*1900*1600

|

|

6.3*2000

|

6.3

|

2000

|

24

|

2°

|

500

|

7.5

|

3180*1765*1500

|

|

8*2000

|

8

|

2000

|

24

|

2°

|

500

|

11

|

3180*1765*1500

|

|

6*2500

|

6

|

2500

|

24

|

2°

|

500

|

7.5

|

3680*2200*2020

|

|

6*3200

|

6

|

3200

|

20

|

1°45'

|

650

|

7.5

|

4300*2250*2150

|

|

8*2500

|

8

|

2500

|

20

|

2°30'

|

650

|

15

|

3680*2250*2450

|

|

13*2500

|

13

|

2500

|

30

|

3°

|

700

|

11

|

3680*2330*2500

|

|

16*2500

|

16

|

2500

|

30

|

3°

|

700

|

22

|

3680*2800*2450

|

|

20*2500

|

20

|

2500

|

25

|

3°

|

750

|

22

|

3950*2800*2900

|

Workshop Overview

Packing & Delivery

Hot Searches