- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

20

-

Range of Spindle Speed(r.p.m):

-

680 - 1050 r.p.m

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Keda

-

Voltage:

-

200/220/380/400/415V

-

Dimension(L*W*H):

-

170*80*130 cm

-

Weight (KG):

-

600 KG

-

Product name:

-

Horizontal sand mill

-

Machine Type:

-

Grinding machine

-

Function:

-

Grinding

-

Capacity:

-

15-100 L

-

Output Size(mesh):

-

680-2000 mesh

Quick Details

-

Output (kg/h):

-

100 - 200 kg/h, 100-2000 kg/h

-

Feeding Size (mm):

-

3 - 10 mm, 30-100 mm

-

Output Size (mesh):

-

900 - 1600 mesh

-

Power (kW):

-

20

-

Range of Spindle Speed(r.p.m):

-

680 - 1050 r.p.m

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Keda

-

Voltage:

-

200/220/380/400/415V

-

Dimension(L*W*H):

-

170*80*130 cm

-

Weight (KG):

-

600 KG

-

Product name:

-

Horizontal sand mill

-

Machine Type:

-

Grinding machine

-

Function:

-

Grinding

-

Capacity:

-

15-100 L

-

Output Size(mesh):

-

680-2000 mesh

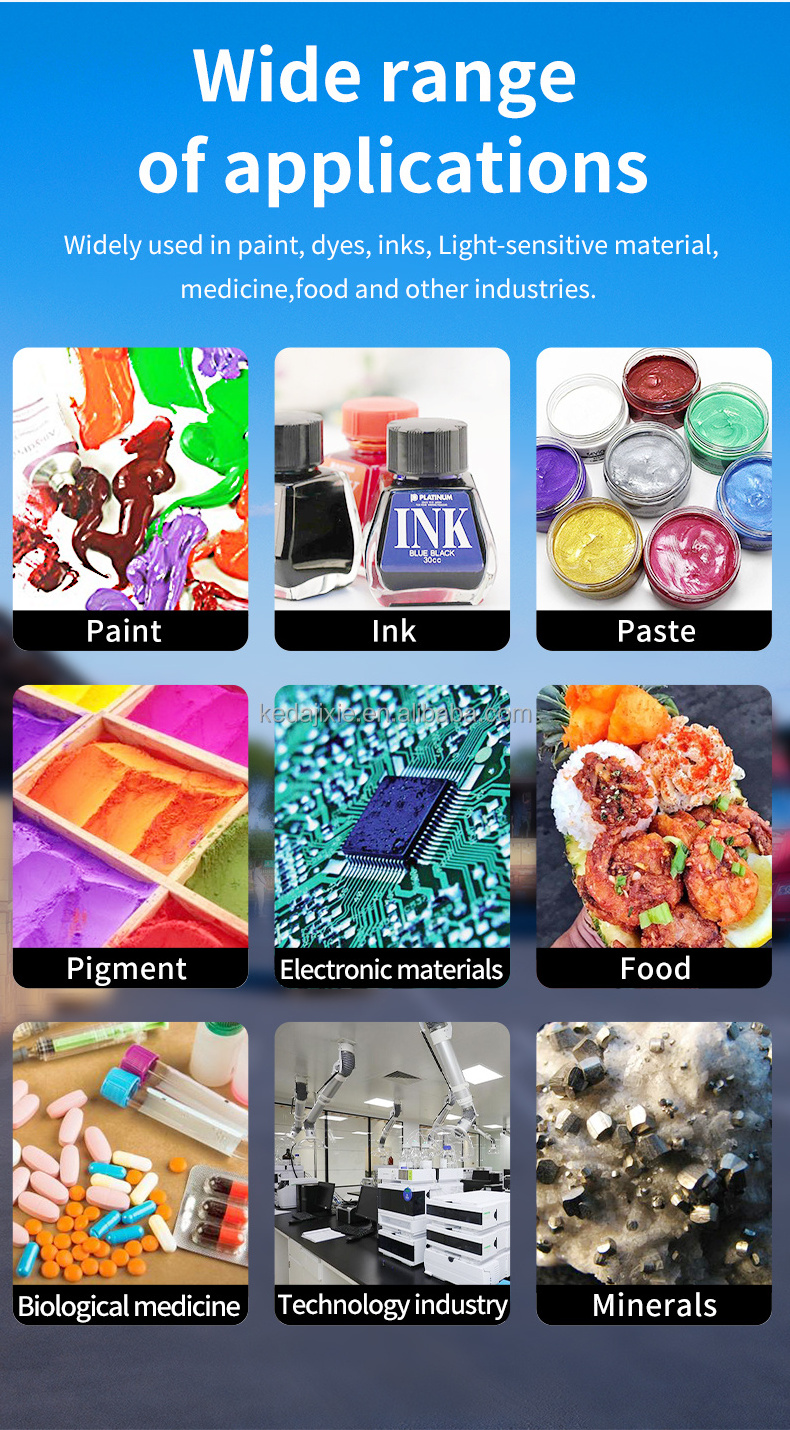

SW series of horizontal closed conical bead mill is the powder material for solid - liquid dispersion grinding of the machinery. Widely used in coatings, dyes, inks, Light-sensitive material, food and other industries.

Horizontal sand mill design novel, compact structure,double end-face mechanical seal, the material in the closed state of production, effectively prevent the material dry, skinning and solvent evaporation, and the machine does not have a special installation basis, you can change the installation location at any time as needed.

The sander also has a dispersion and mixing effect while grinding the material.

Scope of application

-- -

Food:

cocoa, chocolate, nut butters, sauces, mayonnaise, dressings, etc.

-- -

Making paint:

ink, pigment, paste, filler, dye, carbon black.

-- -

Chemicals:

cosmetics, plant protectants, detergents.

-- -

Minerals:

kaolin (China clay), ceramic mud, fireclay.

Horizontal sand mill for printing Ink grinding bead mill machines

Horizontal sand mill for printing Ink grinding bead mill machines

Main Features

1, Fine grinding precision, easy to start, low energy consumption, less material accumulation;

2, Continuous mass production, according to fineness requirements to adjust the speed of incoming and outgoing material;

3, High wear-resisting cylinder body, tungsten carbide material bar pin, staggered balance position, small vibration, low noise;

4, Double end mechanical seal, zero leakage, no pollution, double cooling system, grinding fast heat dissipation;

5, The new dynamic separator and screen ring, output faster, not easy to plug, long service life.

Horizontal sand mill for printing Ink grinding bead mill machines

|

Model

|

|

SW-5

|

SW-15

|

SW-20

|

SW-30

|

SW-50

|

SW-100

|

||||||

|

Dimension mm

|

L

|

600

|

1530

|

1690

|

1690

|

1900

|

2000

|

||||||

|

|

W

|

500

|

800

|

800

|

850

|

900

|

900

|

||||||

|

|

H

|

480

|

1300

|

1300

|

1300

|

1400

|

1600

|

||||||

|

Ex-proof Motor/ kw

|

|

3

|

15

|

18.5

|

22

|

30

|

55

|

||||||

|

Speed / Rpm

|

|

1200

|

1055

|

870

|

870

|

800

|

680

|

||||||

|

Q'ty of dispersion plate/pcs

|

|

4

|

5

|

6

|

8

|

9

|

9

|

||||||

|

Viscosity / Pa.s

|

|

≤10

|

|

|

|

|

|

||||||

|

Weight / kg

|

|

260

|

600

|

700

|

800

|

960

|

2300

|

||||||

|

Drum Material

|

|

Stainless steel with wear-resistant treatment

|

|

|

|

|

|

||||||

|

Dispersion plate material

|

|

Dearing steels, GCr15

|

|

|

|

|

|

||||||

|

Seal

|

|

Double end-face mechanical seal

|

|

|

|

|

|

||||||

|

Grinding Fineness

|

|

Reach below 10 microns after four times grinding

|

|

|

|

|

|

||||||

|

Capacity / kg/8h

|

|

300

|

1000-1500

|

2000

|

2000-2500

|

2500-3000

|

5000-6000

|

||||||