Controlled by oil pump

Automatic cutting as target products length Blade material: Cr12, quenching treatment

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.5-1.2mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Abena

-

Voltage:

-

380v

-

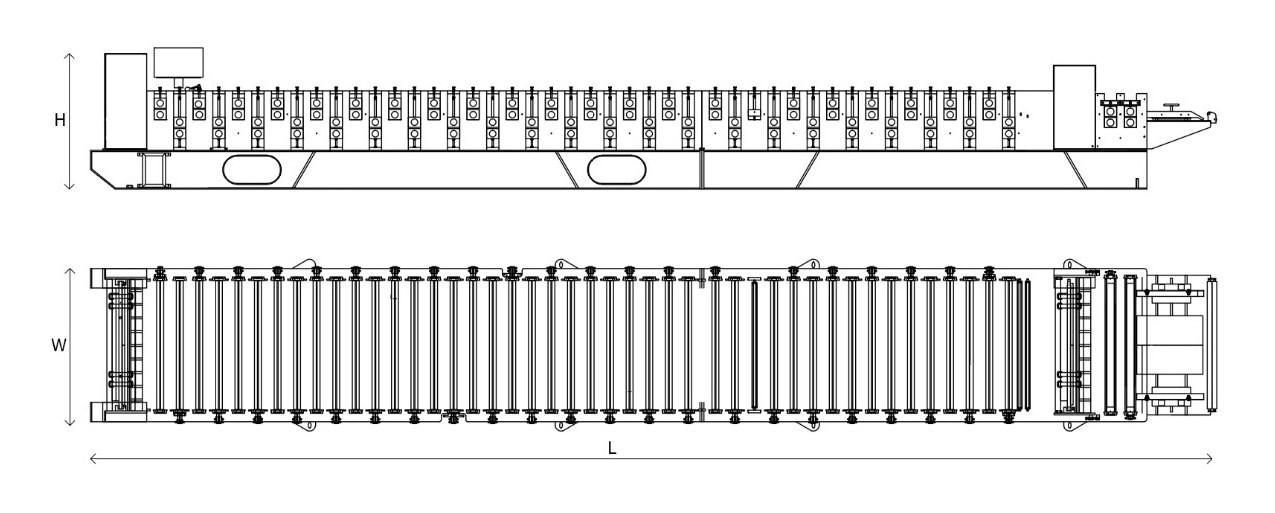

Dimension(L*W*H):

-

4800*1300*1300mm

-

Weight:

-

3500 kg

-

Feeding width:

-

Other

-

Marketing Type:

-

new product 2022

-

Product name:

-

Light Gauge Angle Bead Rangka Dinding C U channel roll Forming Machine

-

Raw material:

-

Steel Coil GI PPGI

-

Cutting blade material:

-

Cr12 Mould Steel

-

Shaft material:

-

High Grade No.45 Steel

-

Control system:

-

PLC(detla) System

-

Certification:

-

CE ISO

-

Main frame:

-

Steel Plate Welded

-

Roller stations:

-

12Stations

-

Motor brand:

-

Lichao

-

Decoiler:

-

5T Manual Decoiler

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

20-40M/MIN

-

Rolling thinckness:

-

0.5-1.2mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Abena

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

4800*1300*1300mm

-

Weight:

-

3500 kg

-

Feeding width:

-

Other

-

Marketing Type:

-

new product 2022

-

Product name:

-

Light Gauge Angle Bead Rangka Dinding C U channel roll Forming Machine

-

Raw material:

-

Steel Coil GI PPGI

-

Cutting blade material:

-

Cr12 Mould Steel

-

Shaft material:

-

High Grade No.45 Steel

-

Control system:

-

PLC(detla) System

-

Certification:

-

CE ISO

-

Main frame:

-

Steel Plate Welded

-

Roller stations:

-

12Stations

-

Motor brand:

-

Lichao

-

Decoiler:

-

5T Manual Decoiler

Product Overview

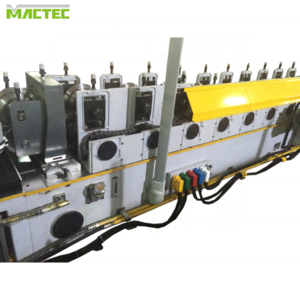

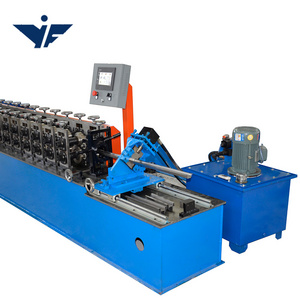

Galvanized metal steel drywall studs and track machine roll former machine

Our company are professional product the

2022 Popular Sale C U channel two profile roll Forming Machine

manufacture , We manufacture and supply variants of light steel keel roll forming machines in China, such as c channel roll forming machine ,u channel roll forming machine , omega roll forming machine .angle bead roll forming machine and so on , our machine export all over the world like india、 south africa 、pakistan 、Brazil 、omen and so no , the shutter door roll forming machine raw material thickness 0.5mm-1.2mm, we also can make other shutter door roll forming machine as your requirement ,meet your need ,our company aim :reputation first, customer first

PRODUCT SPECIFICATIONS

|

No

|

TYPE

|

Data

|

SPECIFICATION

|

|

||

|

1

|

Raw material

|

material

|

PPGI GI

|

|

||

|

2

|

Bucket capacity

|

Feeding width

|

as drawing

|

|

||

|

3

|

Operating weight

|

thickness

|

0.3-1.2mm

|

|

||

|

2

|

Decoiler

|

operate

|

manual

|

|

||

|

5

|

Max. breakout force

|

weight capacity

|

3ton

|

|

||

|

|

|

|

c profile

|

u profile

|

||

|

3

|

Roll forming machine

|

roller station

|

12 row station

|

12 row station

|

||

|

|

|

Diameter of shaft

|

55mm

|

|

||

|

|

|

Roller material

|

45# with 0.05mm chrome

|

|

||

|

|

|

Frame

|

steel sheet welding

|

|

||

|

|

|

Frame thickness

|

16mm

|

|

||

|

|

|

Cutting Material

|

Cr 12

|

|

||

|

|

|

Operation

|

automatic cutting

|

|

||

|

|

|

Working speed

|

15-20m/minute

|

|

||

|

|

Power

|

Driving way

|

chain

|

|

||

|

|

|

Main motor

|

4kw

|

|

||

|

|

|

Voltage

|

380v 50hz

|

|

||

|

|

|

Electric box

|

PLC control system, inventer

|

|

||

|

|

|

PLC brand

|

delta

|

|

||

|

|

|

Inverter brand

|

delta

|

|

||

|

|

|

Language

|

chinese and english

|

|

||

Feature of the C U two profile making machine

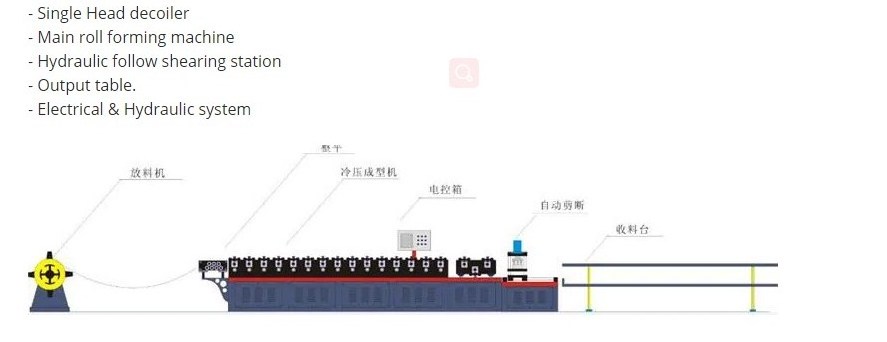

The components of the

2022 Popular Sale C U roll Forming Machine

include: decoiler, roll forming machine body, hydraulic cutting, plc control system, main motor, pump station, receving table.

Equipment features: Suspended C U two profile making machine adopts advanced automatic control software, shutter door machine realizes production information management, and the whole machine automatic control system adopts a highly integrated network, which makes the automation system more superior.

Equipment features: Suspended C U two profile making machine adopts advanced automatic control software, shutter door machine realizes production information management, and the whole machine automatic control system adopts a highly integrated network, which makes the automation system more superior.

Detail image

Hydraulic cutting

Decoiler

Loading capacity: 3tons

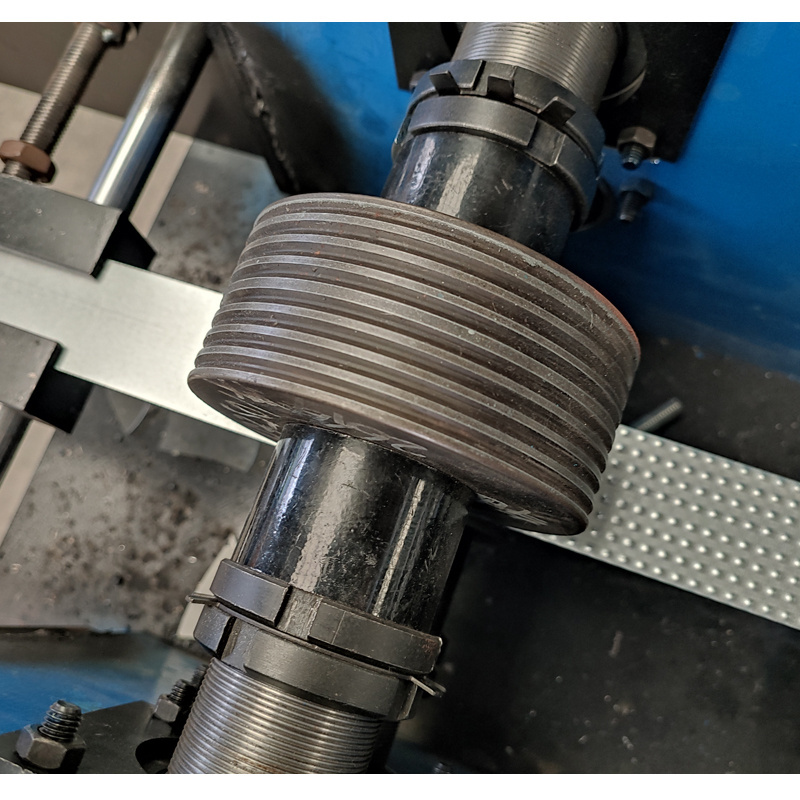

Roll forming body

Roller surfaces polish, hard plating dealing Polished surface and heat treatment towards molds can keep the molding plate surface smooth and not easy to be marked when it is being stamped

computer control system

Button press and screen touch operate Target piece`s length is adjustable Work automatically The system operate easily

Pump station

Hydraulic oil into the hydraulic oil tank, the pump drives the cutter work

Hydraulic oil: 46#

Oil add capacity: oil add 3/4 of box capacity Oil pressure: 8-10 MPa

Hydraulic oil: 46#

Oil add capacity: oil add 3/4 of box capacity Oil pressure: 8-10 MPa

Hot Searches