- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

220V/380V/415V/440V/460V

-

Dimension(L*W*H):

-

Custom size according to model

-

Weight:

-

6500 kg

-

Name:

-

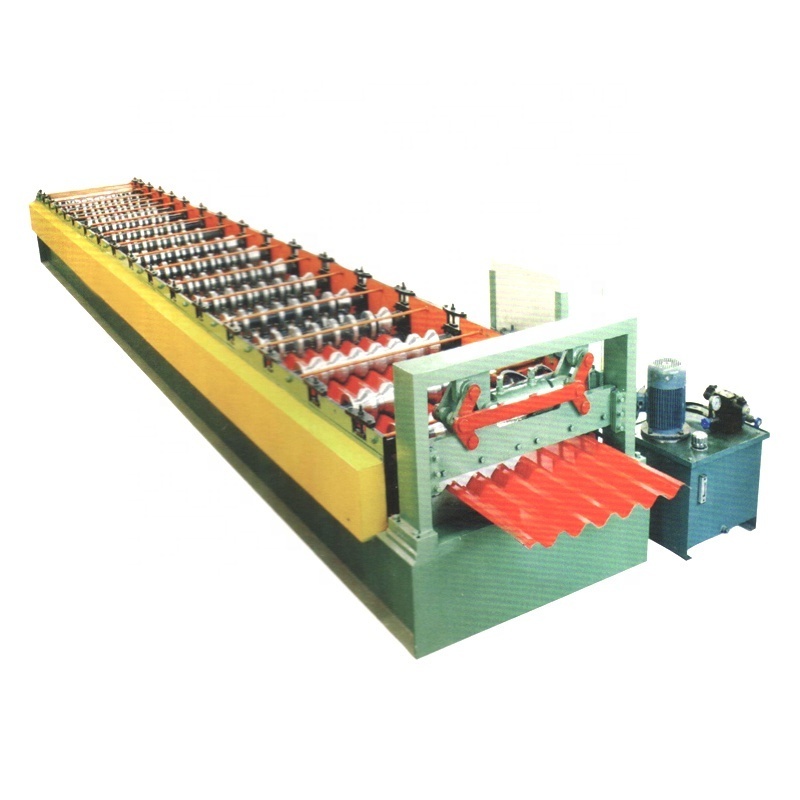

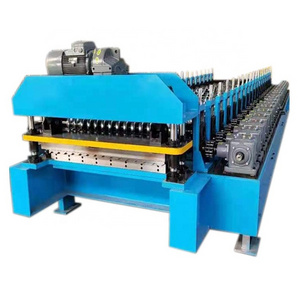

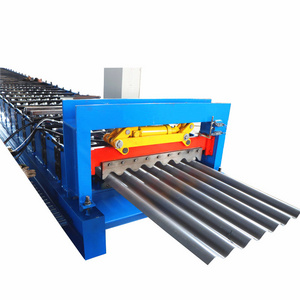

Metal roof panel roll forming machine

-

Working Type:

-

full automatic

-

Hydraulic Station Pump:

-

Gear Pump

-

Control System:

-

PLC Control Panel

-

Touch Screen:

-

Siemens

-

Cutter material:

-

Cr12 , quenched

-

feeding width:

-

as customers requirement

-

Inverter:

-

Schneider

-

Worker Needed:

-

2 workers

-

Request reply:

-

within 24 hours

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Glaze Steel

-

Production Capacity:

-

5-15m/min

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

220V/380V/415V/440V/460V

-

Dimension(L*W*H):

-

Custom size according to model

-

Weight:

-

6500 kg

-

Name:

-

Metal roof panel roll forming machine

-

Working Type:

-

full automatic

-

Hydraulic Station Pump:

-

Gear Pump

-

Control System:

-

PLC Control Panel

-

Touch Screen:

-

Siemens

-

Cutter material:

-

Cr12 , quenched

-

feeding width:

-

as customers requirement

-

Inverter:

-

Schneider

-

Worker Needed:

-

2 workers

-

Request reply:

-

within 24 hours

Roofing Top Sheet Galvanized Steel curving machine Corrugated Glazed zinc Tile Metal Roofing Sheet Making Machine

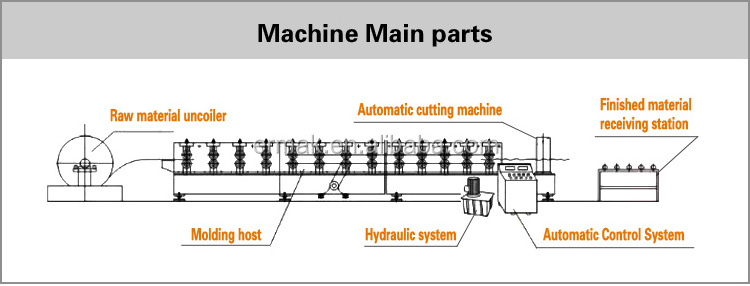

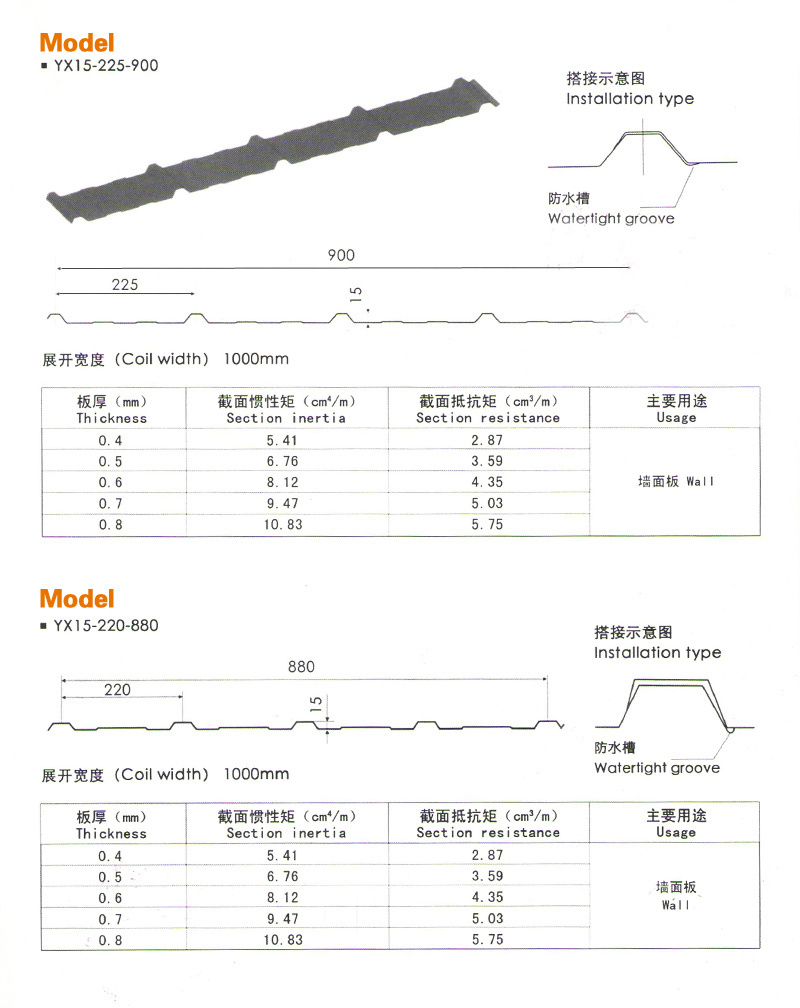

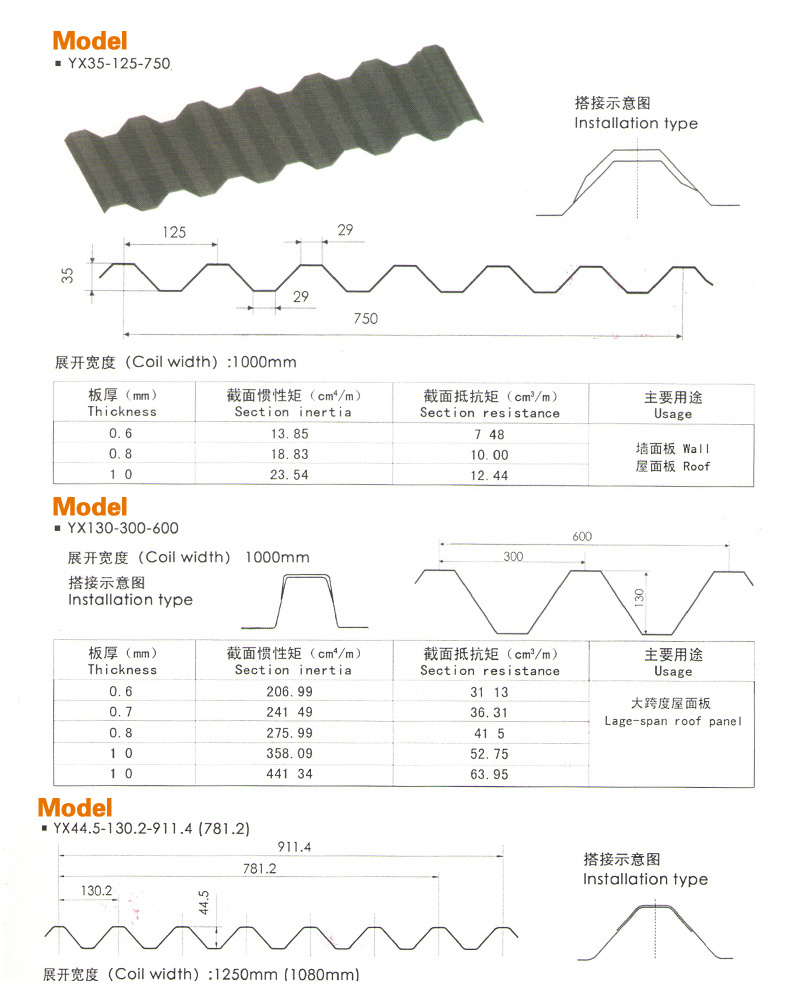

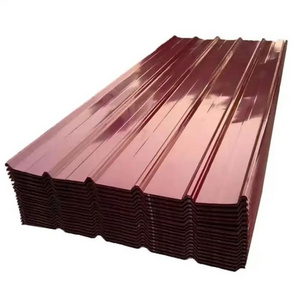

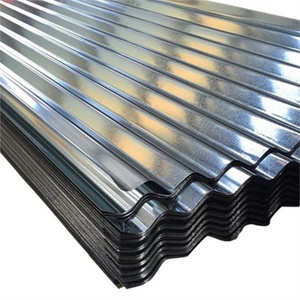

The production size we can design the machine all as customize,customer just show us the profile drawing material thickness width, Different roof panel forming machines can produce different shapes of steel roof wall sheets according to the client’s profile drawings and requirements. The steel roof, wall sheets are new building materials with various thickness and colors. The main products are 840 color steel pressing tile forming machine, 860 color steel pressing tile forming machine, 900 color steel pressing tile forming machine, 1155 color steel pressing tile forming machine, 840/900 double-layer color steel pressing tile forming machine, 860/910 Double-layer color steel tile forming machine, double-layer tile forming machine, water-stopping machine, wall panel forming machine, roofing machine forming machine, angle-pressing tile forming machine, C-shaped steel forming machine, Z-shaped steel forming machine, glazed tile forming Machine, floor board forming tile machine, adjusting guardrail forming machine, automatic hydraulic automatic unwinding machine, leveling machine, etc.

Product Advantage

(1) The color steel plate equipment adopts high-level automatic control software to realize production information management.

(2) The entire unit automation control system uses a highly integrated network to make the automation system perform better.

(3) The color steel tile pressing machine also has the advantages of operation, maintenance, maintenance, mechanical debugging, and easy mold replacement.

Product Description

Applications

The finished products are used as the roof and walls of gymnasiums, airports, theatres, factories, warehouses, garages, exhibition centers etc.

Technical parameter

Guarantee period:

Our product quality guarantee period is 12 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by customers’ incorrect operations, we will provide customers spare parts at cost price. We also can offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Why Choose Us:

1. We will run the machine for a few days, and use your materials to do the test. Only guarantee the machine shows best performance, and then we will ship out.

2. Our elite teams can provide you professional, customized, and all-round services around the clock. If you need any help, contact us by WHATSAPP, Skype, Email or Telephone.

How can we provide you efficient services (metal processing solution):

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional recommendations; reg. non-standard products, we can offer professional designing.