- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2600*6600

-

Power (kW):

-

15.5 kW

-

Weight (KG):

-

30000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training

-

Application:

-

Waste tire oil pyrolysis plant

-

Capacity:

-

10 tons waste tire

-

Oil extraction:

-

45% crude oil

-

Cooling system:

-

Water cooling

-

Heating system:

-

Direct heating

-

Alarm system:

-

Contral Panel

-

Reactor size:

-

Dia 2600mm* L 6600mm

-

Area need:

-

300 square meters

-

Basis:

-

Yes

-

Marketing Type:

-

New Product

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

sihai

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

2600*6600

-

Power (kW):

-

15.5 kW

-

Weight (KG):

-

30000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training

-

Application:

-

Waste tire oil pyrolysis plant

-

Capacity:

-

10 tons waste tire

-

Oil extraction:

-

45% crude oil

-

Cooling system:

-

Water cooling

-

Heating system:

-

Direct heating

-

Alarm system:

-

Contral Panel

-

Reactor size:

-

Dia 2600mm* L 6600mm

-

Area need:

-

300 square meters

-

Basis:

-

Yes

-

Marketing Type:

-

New Product

-

Certification:

-

CE ISO

Used tyre recycling plant waste rubber pyrolysis

About us

S HANGQIU SIHAI ENGRGY TECHNOLOGY CO.,LTD . is a collection of research and development, production, sales and after-sales services, which has rich experience in the field of waste management over 20 years.

Our company covers an area of 37,000 square meters. Our company has a huge professional technical team, including 2 senior engineers, 16 senior technicians, 28 mid-class technicians, and 82 technicians.

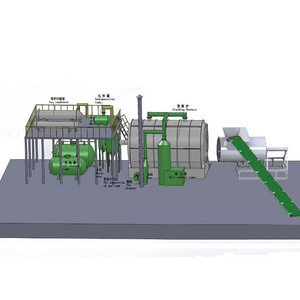

waste tire oil pyrolysis plant

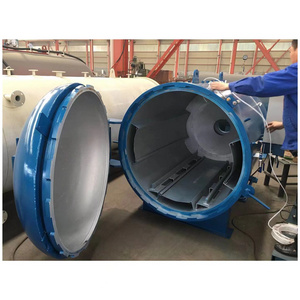

A. horizontal reator

B. oil gas separator

C. vertical condensation system

D. heavy oil tank

E. water seal

F. water tower

G. desulfrization and dedust removal device

H. test pressure and temperature system

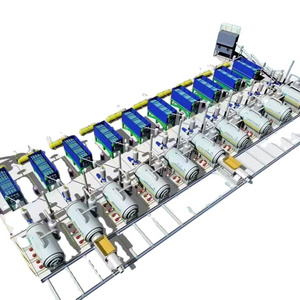

I. control panel

J. electricity control system

K. waste gas burning system

L. pipe and others

waste tire oil pyrolysis plant ---

First , the raw materials are put into the reactor and seal the doors in the reactor

waste tire oil pyrolysis plant ---

Second , start the machine and reactor will rotating and be heated. When the inside

temperature reaches the degree of 250 to 280, the oil gas will begin to generate while flow through oilgas separator, and continuously produce until the temperature up to the degree of 350 to 460.

waste tire oil pyrolysis plant ---

Third, in oil gas separator, light component will enter the condensers, meanwhile,

heavy component will be liquefied and then automatically discharged into heavy oil tank.

waste tire oil pyrolysis plant ---

Forth , most of the light component will be liquefied through condensers to crude oil.

Small amount of oil gas cannot be liquefied and will be transferred by water seal tank back to the burning chamber to be reused as heating fuel. Carbon black will automatically sent from taphole and steel wire will pull out.

| Processing time for one batch | ||||||

| 1.Feeding time | 2.Preheating | 3.Oil producing | 4.Cooling reactor | 5.Discharging slag | 6.Discharge steel wire | Starting next batch |

| 2 hours | 3-4 hour | 8-10 hours | 4 hours | 2 hours |

0.5 hour |

|

| LJ-8 | LJ-9 | LJ-10 | |

| raw material | tire/plastic/rubber | tire/plastic/rubber | tire/plastic/rubber |

| capacity | 5 tons | 8 tons | 10 tons |

| oil extraction | 2.25 tons | 3.6 tons | 4.5 tons |

| reactor structure | horizontal | horizontal | horizontal |

| reactor size | 2.2m*6.6m | 2.2m*6.6* | 2.6m*6.6m |

| working pressure | atmospheric | atmospheric | atmospheric |

| cooling system | water | water | water |

| heating method | direct | direct | direct |

| power | 12kw | 12kw | 15.5kw |

| package | 2*40HQ | 2*40HQ | 1*40HQ+1*40FR |

| area need | 300sqm | 300sqm | 300sqm |

| workers need | 2-3 workers | 2-3 workers | 2-3 workers |

| life | 5-8 years | 5-8 years | 5-8 years |

| warranty | lifetime | lifetime | lifetime |

| installation | free | free | free |

| environment | no pollution | no pollution | no pollution |

| accessory products | carbon black, steel wire, gas | carbon black, steel wire, gas | carbon black, steel wire, gas |

waste tire oil pyrolysis plant ---The fuel for heating can be coal, oil, gas & firewood. Gas production during the process can be used, and energy saving.

waste tire oil pyrolysis plant --- The ensured safety system:

1. Auto open pressue relieve valve in gas seperator two pcs

2. Auto explosed safety place in reactor door one pcs

3. Air relieve valve in gas seperator one pcs

4. Auto Alarm system. Pressure gauge to monitor the pressure inside the reactor.

If it goes abnormally, the bell will alarm and the safety valves will release the pressure automatically.

waste tire oil pyrolysis plant --- Environmental protection

1. Acid-base Neutralization SO2 Removal Our dust and sulfur removal system according to

acid-base neutralization to remove the dust and SO 2 which is from heating system to

protect the environment.

2. Recovering The Exhaust Flammable Gas For Fuel

| America : | Brazil , Canada, Colombia, USA, |

| Middle East : | Dubai , Jordan, Saudi Arabia, Turkey |

| Europe : | Albania , Bosnia and Herzegovina |

| Asia : | Afghanistan , India, Malaysia, Pakistan, Philippines, South Korea, Vietnam, Myanmar,Thailand, Uzbekistan |

| Africa : | Ghana , Mozambique, Zambia |

seaworthy package LIANYUNGANG PORT

1*40FR(open container) +

1*40HQ