- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50Hz , 220V 50hz

-

Dimension(L*W*H):

-

860*860*1560mm

-

Power (kW):

-

12kw

-

Weight (KG):

-

280 KG

-

Product Name:

-

High pressure polyurethane and polyurea spray foam machine

-

Application:

-

walls, cold storage, roof, insulation tanks, road construction

-

Material:

-

A+B

-

Driven mode:

-

pneumatic

-

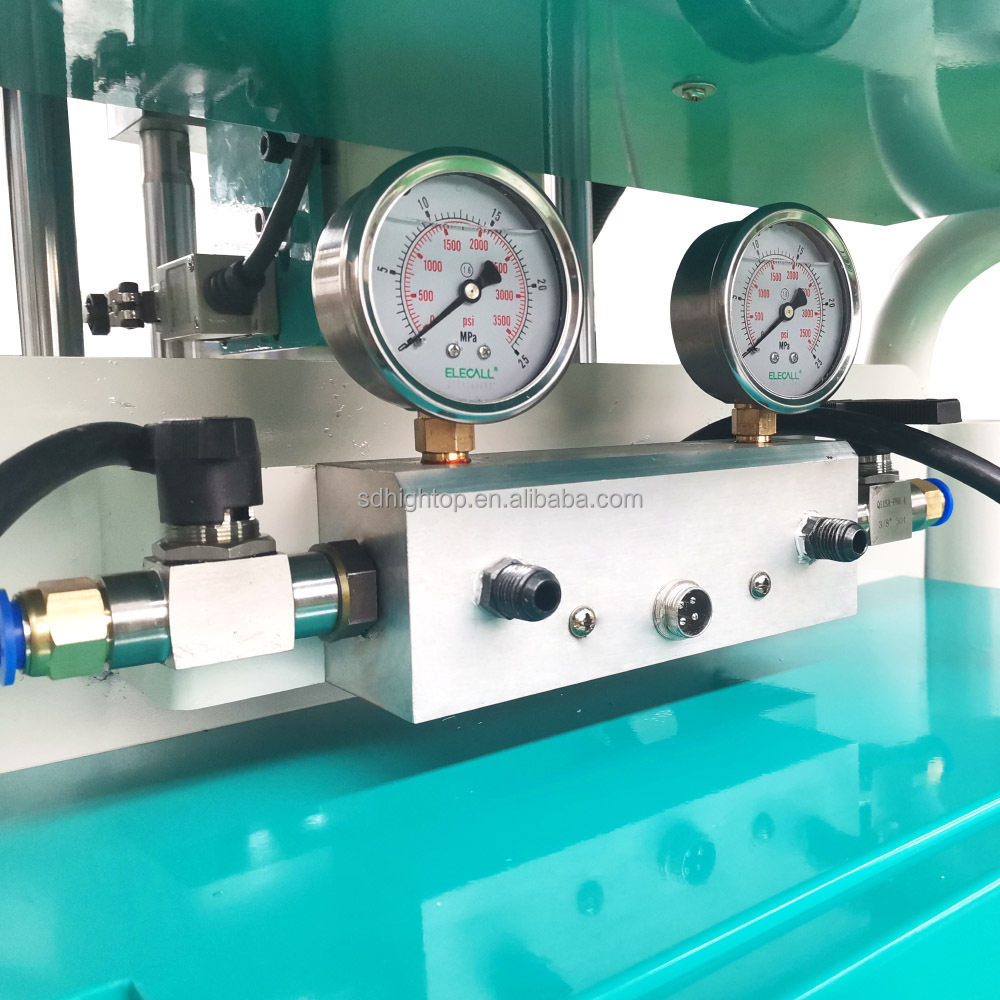

Pressure:

-

high pressure

-

AB material output ratio:

-

1:1

-

Raw output:

-

2~12 kg/min

-

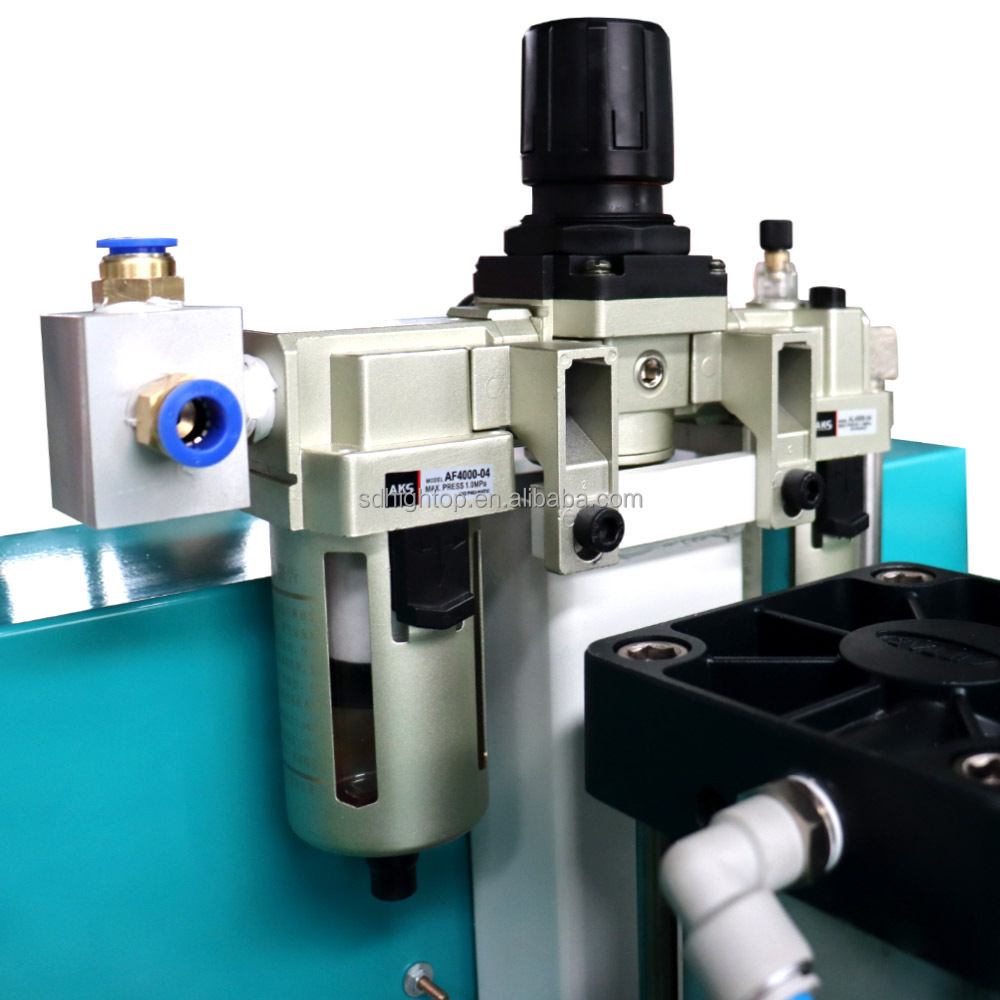

Air Source:

-

0.3~0.8 MPa ≥0.9 m 3 /min

-

Maximum output pressure:

-

15Mpa

-

Keywords:

-

Polyurethane Foam Machine

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CNMC

-

Machine Type:

-

pneumatic

-

Voltage:

-

380V 50Hz , 220V 50hz

-

Dimension(L*W*H):

-

860*860*1560mm

-

Power (kW):

-

12kw

-

Weight (KG):

-

280 KG

-

Product Name:

-

High pressure polyurethane and polyurea spray foam machine

-

Application:

-

walls, cold storage, roof, insulation tanks, road construction

-

Material:

-

A+B

-

Driven mode:

-

pneumatic

-

Pressure:

-

high pressure

-

AB material output ratio:

-

1:1

-

Raw output:

-

2~12 kg/min

-

Air Source:

-

0.3~0.8 MPa ≥0.9 m 3 /min

-

Maximum output pressure:

-

15Mpa

-

Keywords:

-

Polyurethane Foam Machine

High pressure polyurethane and polyurea spray foam machine

Polyurethane foam machine is can be used for various construction environment with spraying two-component materials spray(optional) like polyurethane foaming materials, widely used in embankment waterproof, pipeline corrosion, auxiliary cofferdam,tanks, pipe coating, cement layer protection, wastewater disposal,roofing, basement waterproofing, industrial maintenance, wear-resistant linings, cold storage insulation, wall insulation and so on.

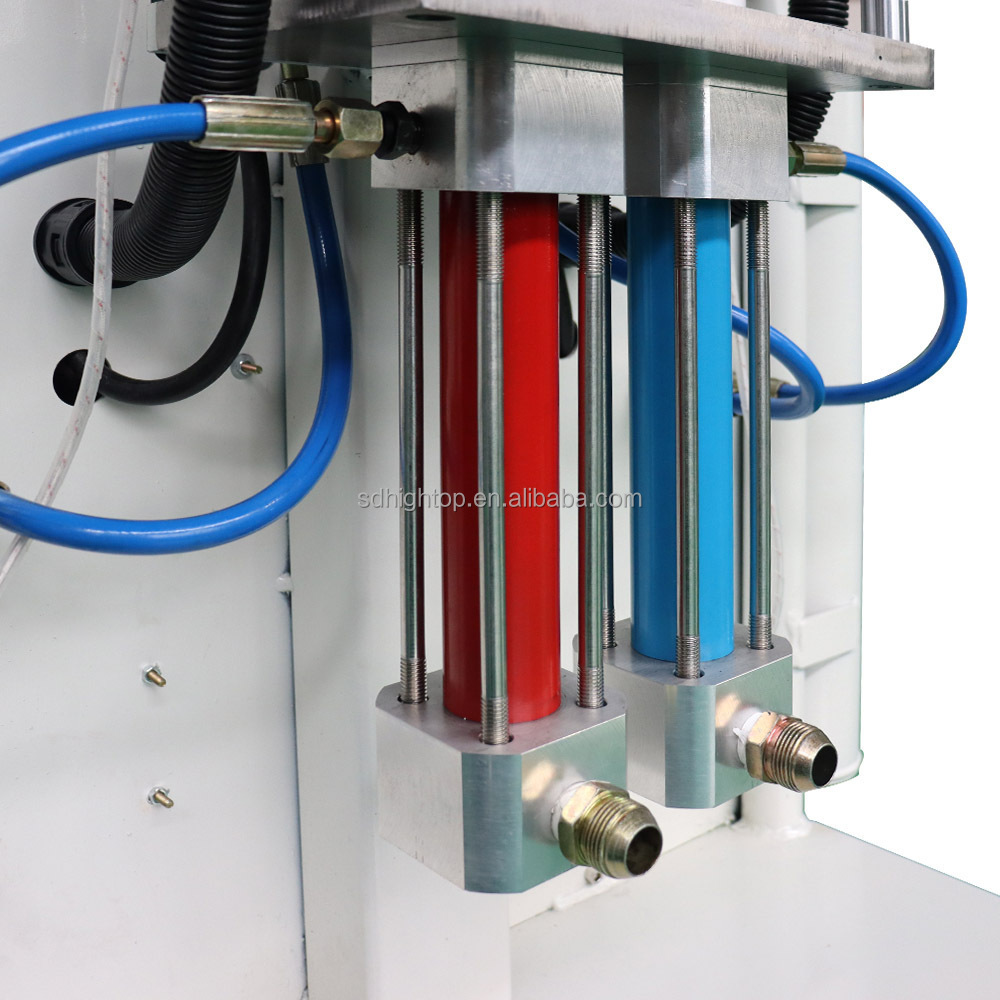

This machine can spray two component polyurea very well, because it has two air cylinder to offer powerful force.

Features :

1. The use of a

large power cylinder

makes the spraying more powerful and the atomization effect better.

2. The heated hose of the new Upgrade machine CNMC-E3 heats up faster.

In cold winter, the machine can pre heat

the foam chemicals rapidly to help save time and improve spraying effect and foaming effect. Equipped with a reflux

valve, it is very convenient for the operator to cycle the chemicals.

3. The machine contains the

electric leakage protector

to prevent machine leakage and human electric shock, and

improve the safety performance of the machine.

4.

Adding Voltmeter and Ammeter

, so the voltage and current conditions inside the machine can be detected.

5. Appearance design conforms to the principle of artificial mechanics, moving the machine is easier.

6.

The heated hose is with internal heating and low voltage current

, to protect the operator's personal safety to

the greatest extent.

7. The quick opening door is installed ,Machine maintenance and repair and inspection will be more convenient