- Product Details

- {{item.text}}

Quick Details

-

Power:

-

1.1-6.5W/CM2

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

vsec

-

Model Number:

-

band heater

-

Dimension(L*W*H):

-

Custom Size

-

Weight:

-

Based

-

Product name:

-

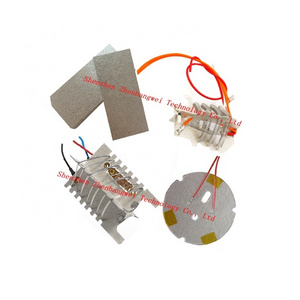

mica band heater

-

Material:

-

SS304,316,321

-

Insulation material:

-

mica

-

connector:

-

lead wire/ceramic terminal/plug

-

Certification:

-

CE ROHS

Quick Details

-

Type:

-

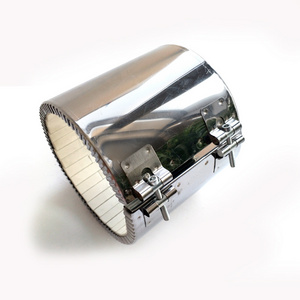

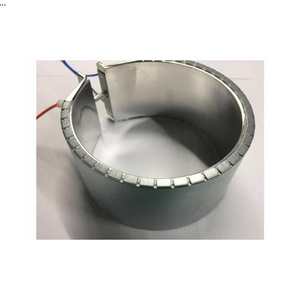

Band Heater

-

Power Source:

-

Electric

-

Voltage:

-

12-480v

-

Power:

-

1.1-6.5W/CM2

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

vsec

-

Model Number:

-

band heater

-

Dimension(L*W*H):

-

Custom Size

-

Weight:

-

Based

-

Product name:

-

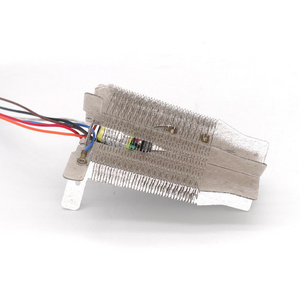

mica band heater

-

Material:

-

SS304,316,321

-

Insulation material:

-

mica

-

connector:

-

lead wire/ceramic terminal/plug

-

Certification:

-

CE ROHS

Mica heater is a highly efficient thermal division of the heater, excellent thermal conductivity of the metal alloy to ensure that the hot surface temperature uniformity, eliminating the hot and cold spots of the device. With long working life, good insulation properties, mechanical properties, corrosion resistance, anti-magnetic field and so on. The external cooling surface to increase the insulation device, the heat sink sintering infrared can save 35% of electricity.

Features:

- The sheath of the heater is rust resistance.

- High class Nickel Chrome ribbon is used.

- Maximum power: 3w/cm2(s.steel),4.5w/cm2 ( brass ) ,6.5w/cm2 ( ceramic insulation )

- Operating temperature up maximum of 500 degree centigrade

- Axial, Radial & Tangential terminals are available

- Thermocouple holes can be provided as per client's requirements

| Insulation resistance | ≥ 100 MΩ |

| Working temperature | -20 ~ 400 ℃ |

| Power deviation range | ± 10%. |

| Voltage | customize |

| Power | 0.5-3.5w / cm2 |

| Pressure | 1500V / 1min |

| Application | Injection molding,Blow-molding,Plastic extrusion,Container, pipe, or tank heating,and so on |

mica heater instructions:

Ø The working voltage shall not exceed 10% of the rated value;

Ø wiring part of the heating layer, insulation layer, the shell should be effectively grounded;

Ø should be kept in a dry place.