- Product Details

- {{item.text}}

Quick Details

-

Working pressure:

-

0.7MPa-2.5MPa

-

Rated steam temperature:

-

170℃-225℃

-

Efficiency of steam boiler:

-

>81%

-

Voltage of food steam boiler:

-

380V,optional

-

Food machinery steam boiler:

-

single drum

-

DZL Food steam boiler:

-

Three-return water and fire tube

-

Warranty of food steam boiler:

-

2 Years

-

Product name:

-

Biomass Steam Boiler for Dry Cleaning Machine Price

Quick Details

-

Place of Origin:

-

Henan, China

-

Controller:

-

PLC Screen

-

Nominal capacity:

-

1t/h-25t/h

-

Working pressure:

-

0.7MPa-2.5MPa

-

Rated steam temperature:

-

170℃-225℃

-

Efficiency of steam boiler:

-

>81%

-

Voltage of food steam boiler:

-

380V,optional

-

Food machinery steam boiler:

-

single drum

-

DZL Food steam boiler:

-

Three-return water and fire tube

-

Warranty of food steam boiler:

-

2 Years

-

Product name:

-

Biomass Steam Boiler for Dry Cleaning Machine Price

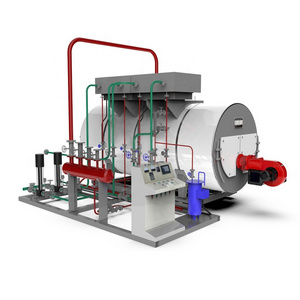

List of Boiler Manufacturers Biomass Steam Boiler for Dry Cleaning Machine Price

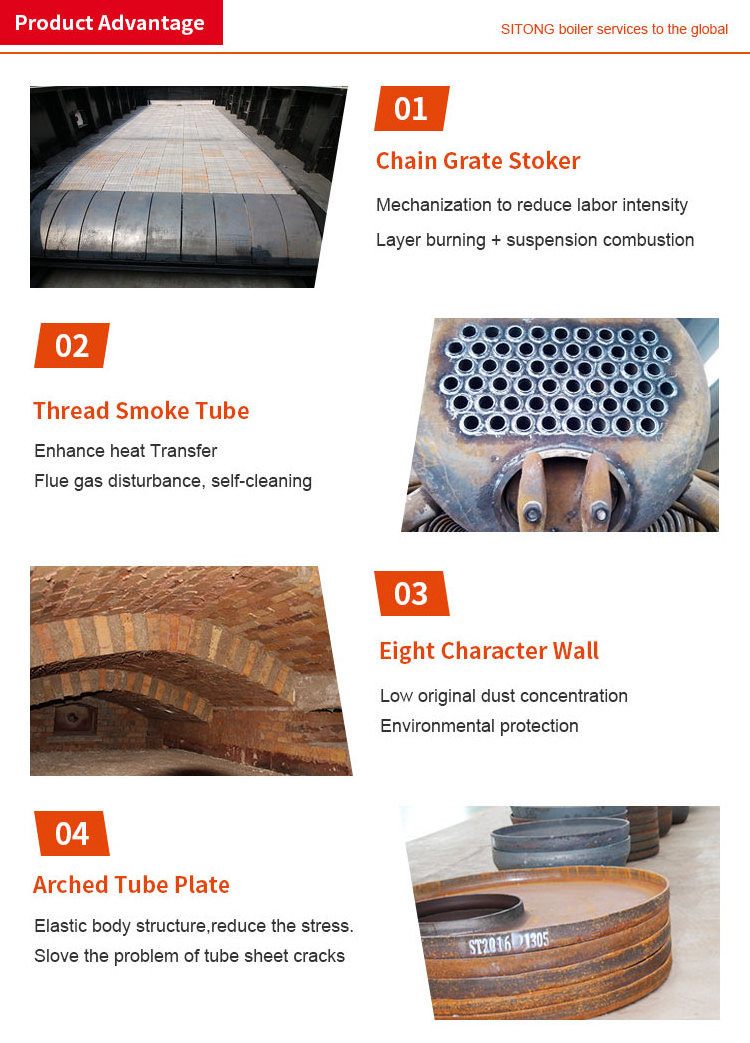

Model:DZLType Chain Grate Stoker Boiler

Structure:WaterTube Fire Tube Three Pass

Rated Steam Capacity:1-20 ton/hr

Rated Steam Pressure:0.7/1.0/1.25/1.6/2.5 Mpa

Rated Steam Temperature:170/184/194/204/225 C

Application:Textile Mill,Food and Beverage,Chemical,Medicine,Light Industry,Rubber,Printing and Dyeing Plant,Paper Mill,Wood Processing,Garment and Laundry etc.

|

Model

Item |

DZL1-0.7-AII

DZL1-1.0- AII DZL1-1.25- AII |

DZL2-0.7- AII

DZL2-1.0- AII DZL2-1.25- AII |

DZL4-1.25- AII

DZL4-1.6- AII |

DZL6-1.25- AII

DZL6-1.6- AII |

DZL8-1.25- AII

DZL8-1.6- AII |

DZL10-1.25- AII

(Assembly) |

DZL20-1.6-AII

DZL20-2.5-AII (Assembly) |

|

|

Steam Capacity

(t/h) |

1 | 2 | 4 | 6 | 8 | 10 | 20 | |

|

Steam Pressure

(MPa) |

0.7/1.0/1.25 | 1.25/1.6 | ||||||

|

Steam Temperature

(℃) |

170/184/194 | 194/204 | ||||||

|

Feed water Temperature(℃) |

20 | 20 | 20 | 20 | 20 | 70 | 70 | |

|

Heating Area(m2) |

Body | ~33 | ~50 | ~100 | ~170 | ~200 | ~250 | 502 |

| Economizer | 10.56/10.56/20.7 | 27.6 | 52.48/33.12 | 87.2 | 98 | 174 | 382 | |

|

Effective Grate

Area(m2) |

2.22 | 2.22 | 4.1 | 5.5 | 7.95 | 9.75 | 23.9 | |

| Fuel Type | II Bituminous Coal, Lower Heating Value Q≈21000KJ/Kg | |||||||

|

Fuel Consumption (kg/h) |

~151 | ~302 | ~600 | ~880 | ~1150 | ~1450 | ~1160 | |

|

Exhaust Gas Temperature(℃) |

135-145 | |||||||

|

Thermal Efficiency (%) |

83-85 | |||||||

|

Weight of Biggest Part for Transportation(t) |

17 | 23 | 25 | 35 | 45 |

33(Up Part)

28(Down Part) |

50(Up Part)

28(Down Part) |

|

|

Overall Dimension of

Boiler Assembled

|

5.1×2.2×3 | 5.5×2.3×3.3 | 6.6×2.6×3.6 | 7.5×2.9×3.8 | 8.1×3.1×3.8 |

7.7×3.2×3.6

8.6×3.0×2.6 |

11×3.24×3.54

14×3.2×3.08 |

|

1.. What are the differences between vertical type boiler and horizontal type boiler with the same capacity?

1. Structure of vertical boiler is compact, occupy a limited area,

2. Convenient on installation and removal.

3. Low cost and investment on capital construction. Steam exhausted fast and sufficient.

1. The combustion space of horizontal is big, fuel can be burned completed.

2. The thermal efficiency is higher than the vertical boiler,

3. Horizontal type: less thermal loss, stronger output, and higher steam quality.

2. What are the limitation (size, humidity, chemical element concentrations) of coal fuel/solid fuel/wood fuel?

Size requirement of coal:6-25mm

Size requirement of blending coal: <50mm (the coal less than 6mm should less than 30%)

Diameter of biomass particle: 6~10mm, length: 25~50mm, water content < 15%, ash content < 2%, sulphur content<0.07%, chlorinity <0.07%, nitrogen content < 0.5%

3. What is the size of furnace door and blower hopper?

Size of furnace door:

Standard elliptical furnace door:300*800*1500

Blower hopper size:

2 tons conical hopper: 1400*800*1500

4 tons conical hopper: 2200*1400*1500

4. What is the combustion mode of coal/biomass fired boiler?

The combustion mode of coal/biomass fired boiler is layer combustion. Place the flue on the fixed or moved grate, to form an evenly fuel bed with a certain thickness, air comes from the bottom of grate, and combustion occurred on the fuel bed.