Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

ROOF

-

Design Style:

-

Traditional

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

vegas

-

Model Number:

-

001

-

Product Name:

-

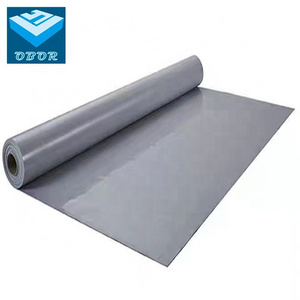

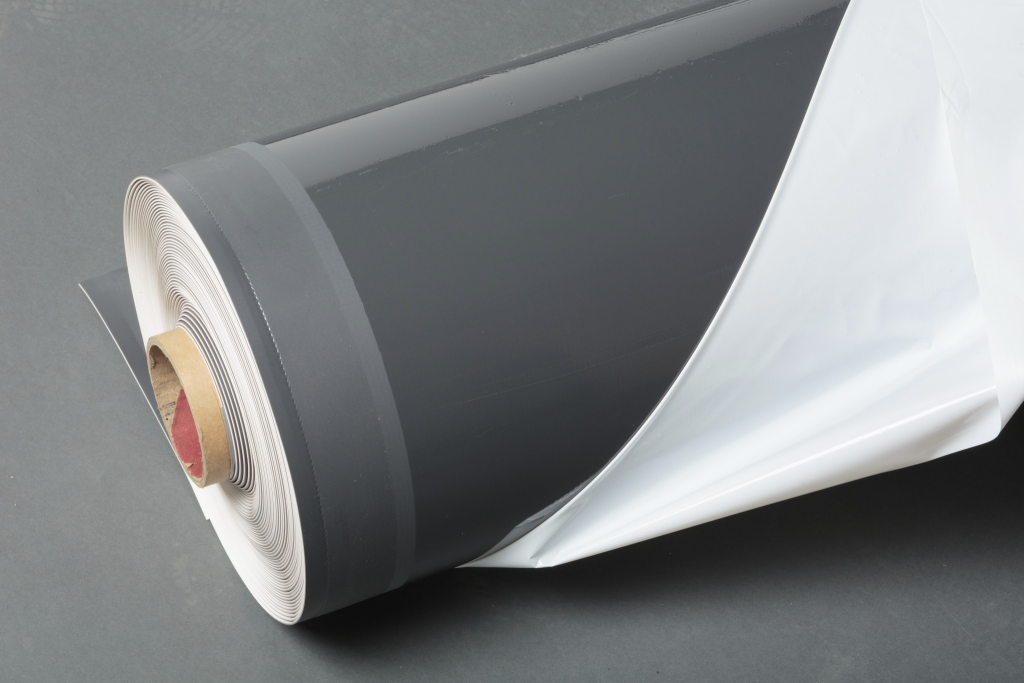

TPO Waterproof Membrane

-

Main material:

-

EP Rubber

-

Type:

-

Waterproof Menbrane

-

Color:

-

Black White

-

Packing:

-

Pallets

-

Usage:

-

Roof Waterproof Projects

-

Keyword:

-

Roof Flexible Membrane

-

MOQ:

-

3000M2

-

Standard:

-

ASTM

-

Advantage:

-

Non-toxic

Quick Details

-

Warranty:

-

5 years

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

-

Application:

-

ROOF

-

Design Style:

-

Traditional

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

vegas

-

Model Number:

-

001

-

Product Name:

-

TPO Waterproof Membrane

-

Main material:

-

EP Rubber

-

Type:

-

Waterproof Menbrane

-

Color:

-

Black White

-

Packing:

-

Pallets

-

Usage:

-

Roof Waterproof Projects

-

Keyword:

-

Roof Flexible Membrane

-

MOQ:

-

3000M2

-

Standard:

-

ASTM

-

Advantage:

-

Non-toxic

Products Description

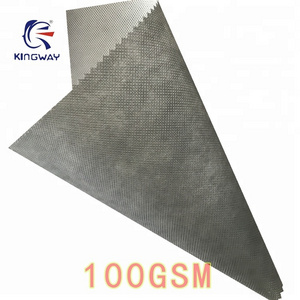

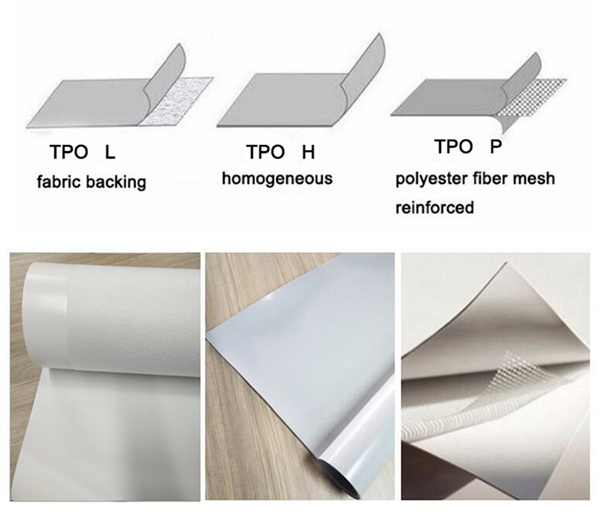

TPO waterproof coil is thermoplastic polyolefin waterproof coil. It is a new waterproof coil made of thermoplastic polyolefin

(TPO) synthetic resin which combines ethylene propylene rubber and polypropylene by using advanced polymerization technology as

the base material, adding antioxidant, antioxidant and softener. It can be made of polyester fiber mesh cloth as the internal

reinforcement material to make enhanced waterproof coil. It is a waterproof product of synthetic polymer waterproof coil

(TPO) synthetic resin which combines ethylene propylene rubber and polypropylene by using advanced polymerization technology as

the base material, adding antioxidant, antioxidant and softener. It can be made of polyester fiber mesh cloth as the internal

reinforcement material to make enhanced waterproof coil. It is a waterproof product of synthetic polymer waterproof coil

Details Show

|

NO.

|

Item(TPO waterproof coil with strong weather resistance and fracture resistance)

|

|

Indicator Executive standard:GB 27789-2011

|

|

|

|||

|

|

|

|

H

|

L

|

P

|

|||

|

1

|

Thickness of resin layer above intermediate substrate/mm ≥

|

|

|

|

0.4

|

|||

|

2

|

tensile property

|

maximum tension/(N/cm) ≥

|

|

200

|

250

|

|||

|

|

|

tensile strength/Mpa ≥

|

12.0

|

|

|

|||

|

|

|

Elongation at maximum tension/% ≥

|

|

|

15

|

|||

|

|

|

elongation at break /% ≥

|

500

|

250

|

|

|||

|

3

|

Heat treatment size change rate /% ≤

|

|

2.0

|

1.0

|

0.5

|

|||

|

4

|

Low temperature flexability

|

|

-40℃ Nocrack

|

|

|

|||

|

5

|

unpermeability

|

|

0.3MPa,2h impermeable

|

|

|

|||

|

6

|

shock resistance

|

|

0.5kg.m,impermeable

|

|

|

|||

|

7

|

Resistance to static load

|

|

|

|

20kg impermeable

|

|||

|

8

|

Joint stripping strength/(N/mm) ≥

|

|

4.0 or coil damage

|

|

3

|

|||

|

9

|

Right-angle tearing strength/(N/mm) ≥

|

|

60

|

|

|

|||

|

10

|

Trapezoidal tearing strength/N ≥

|

|

|

250

|

450

|

|||

|

11

|

water absorption(70℃ 168h)/%

|

|

4

|

|

|

|||

|

12

|

thermal ageing(115℃)

|

Time/h

|

672

|

|

|

|||

|

|

|

appearance

|

No bubbling, cracking, delamination, bonding and porosity

|

|

|

|||

|

|

|

Maximum tensile retention/% ≥

|

90

|

|

90

|

|||

|

|

|

Tensile strength retention rate/% ≥

|

90

|

|

|

|||

|

|

|

Elongation retention at maximum tension/% ≥

|

|

|

90

|

|||

|

|

|

Elongation at break retention rate/% ≥

|

90

|

90

|

|

|||

|

|

|

Low temperature flexability

|

-40℃ no crack

|

|

|

|||

|

13

|

chemical resistance

|

appearance

|

No bubbling, cracking, delamination, bonding and porosity

|

|

|

|||

|

|

|

Maximum tensile retention/% ≥

|

|

90

|

90

|

|||

|

|

|

Tensile strength retention rate/% ≥

|

90

|

|

|

|||

|

|

|

Elongation retention at maximum tension/% ≥

|

|

|

90

|

|||

|

|

|

Elongation at break retention rate/% ≥

|

90

|

90

|

|

|||

|

|

|

Low temperature flexability

|

-40℃ no crack

|

|

|

|||

|

14

|

artificial weathering test

|

Time/h

|

1500

|

|

|

|||

|

|

|

appearance

|

No bubbling, cracking, delamination, bonding and porosity

|

|

|

|||

|

|

|

Maximum tensile retention/% ≥

|

|

90

|

90

|

|||

|

|

|

Tensile strength retention rate/% ≥

|

90

|

|

|

|||

|

|

|

Elongation retention at maximum tension/% ≥

|

|

|

90

|

|||

|

|

|

Elongation at break retention rate/% ≥

|

90

|

90

|

|

|||

|

|

|

Low temperature flexability

|

-40℃,No crack

|

|

|

|||

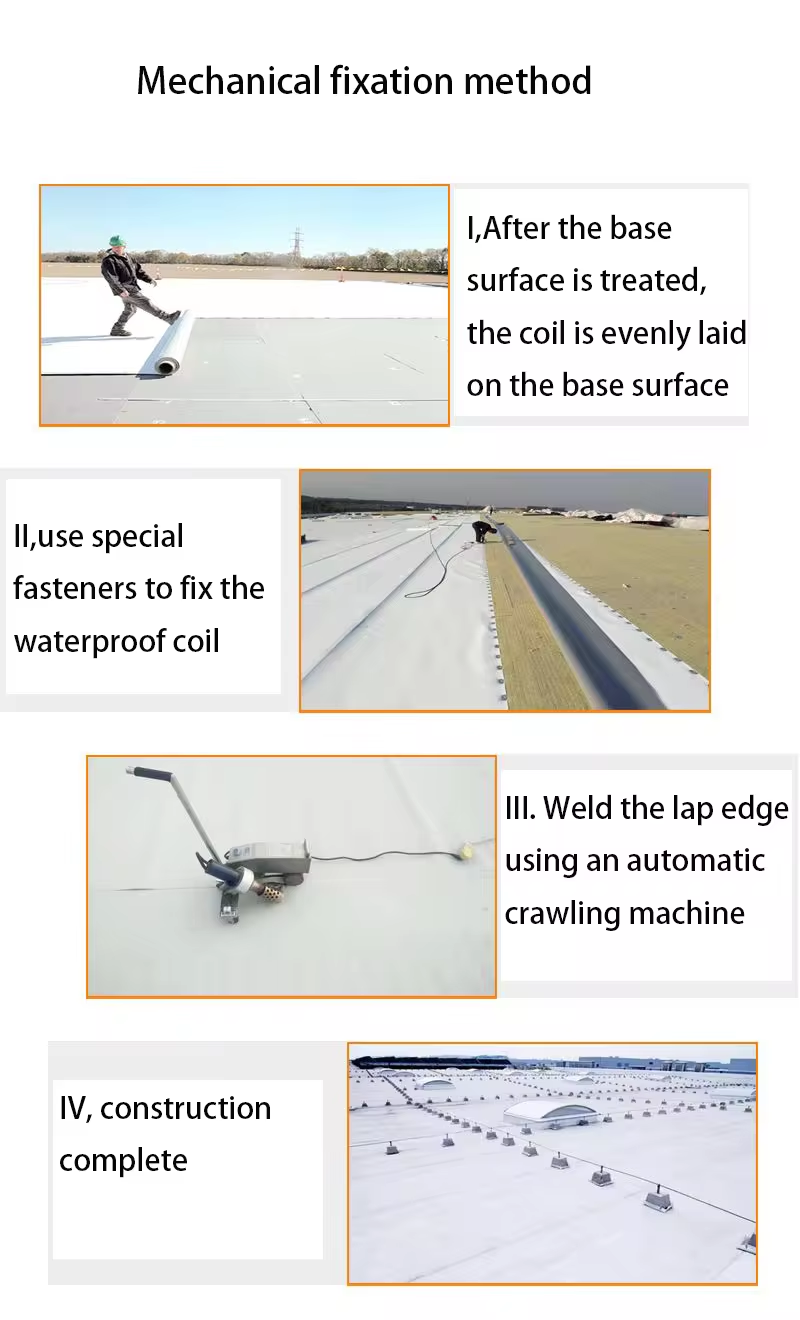

How to install ?

Application

This product is suitable for building exposed or non-exposed roof waterproof layer, and easily deformed building underground

waterproof. Especially suitable for light steel structure roof, with reasonable level design and qualified construction quality,

not only to reduce the weight of the roof, but also have excellent energy saving effect, but also to achieve waterproof and dew prevention, is the preferred waterproof material for large industrial plants, public buildings and other roofing.

It can also be used in drinking water reservoirs, toilets, basements, tunnels, grain depots, subways, reservoirs and other waterproof and moisture-proof projects

waterproof. Especially suitable for light steel structure roof, with reasonable level design and qualified construction quality,

not only to reduce the weight of the roof, but also have excellent energy saving effect, but also to achieve waterproof and dew prevention, is the preferred waterproof material for large industrial plants, public buildings and other roofing.

It can also be used in drinking water reservoirs, toilets, basements, tunnels, grain depots, subways, reservoirs and other waterproof and moisture-proof projects

Company profile

As a technological innovation-based enterprise, Shandong Vegas Engineering Materials Co., Ltd is a professional manufacturer in all kindsof geosynthetics in China.

vegas owns the domestic advanced automatic production lines and the quality inspection testing equipments. All the products designed and manufactured by our company meet the national standards.

With 30 years experience in manufacturing all kinds plastic products, we are specialized in producing excellent HDPE geocell, HDPE/LDPE geomembrane, PP woven geotextile, non-woven geotextile as well as other product used in building materials which are mainly used in the foundation construction. Most our products are exported to more than 60 countries, such as Australia, Brazil, Russia, South Korea, Japan, Southeast Asia, North American, Europe, etc.

Product Details

Contact

Thank you for your interest in our products, we are ready to support your project

Hot Searches