- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

71

-

Weight (KG):

-

4600

-

Application:

-

Polishing

-

Usage:

-

Workpieces Surface Deburring Polishing

-

Keyword:

-

Metal Surface Polishing Machine

-

Polishing material:

-

Abrasive Belt

-

After-sales Service Provided:

-

Online Support

-

Advantage:

-

High Working Efficiency

-

Type:

-

Fully Automatic

-

Model:

-

R-RD1300

-

Voltage:

-

380V 50Hz 3Phase/Customized

-

Polishing work piece material:

-

Steel Iron Parts

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

NEWSTEC

-

Marketing Type:

-

Hot Product 2022

-

Power (kW):

-

71

-

Weight (KG):

-

4600

-

Application:

-

Polishing

-

Usage:

-

Workpieces Surface Deburring Polishing

-

Keyword:

-

Metal Surface Polishing Machine

-

Polishing material:

-

Abrasive Belt

-

After-sales Service Provided:

-

Online Support

-

Advantage:

-

High Working Efficiency

-

Type:

-

Fully Automatic

-

Model:

-

R-RD1300

-

Voltage:

-

380V 50Hz 3Phase/Customized

-

Polishing work piece material:

-

Steel Iron Parts

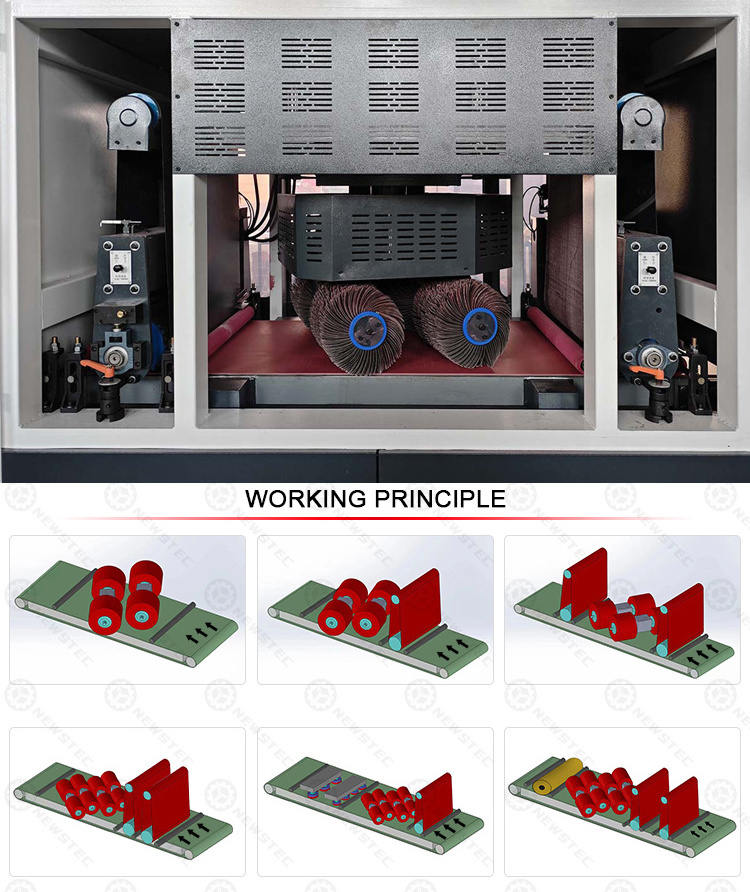

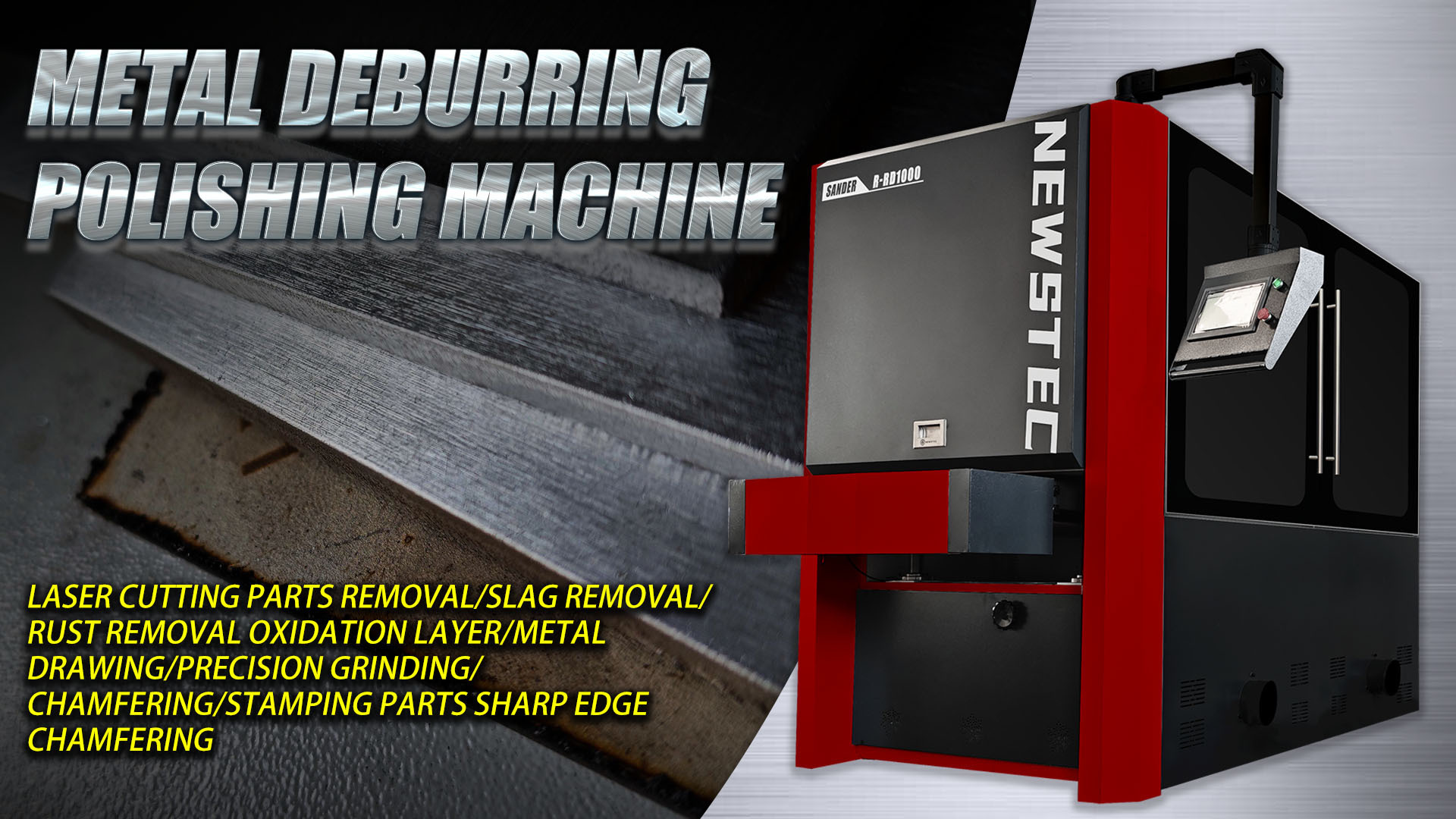

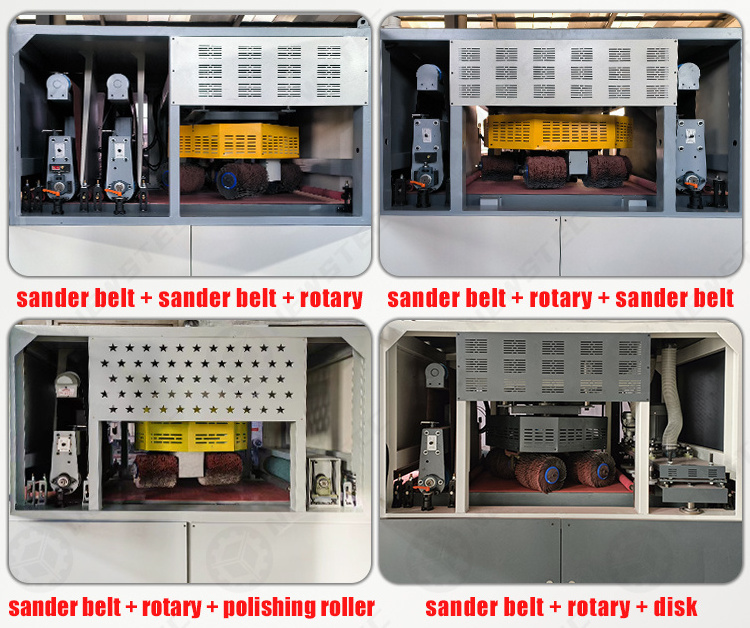

Matching laser cutting machine, CNC stamping, a variety of CNC processing or other machining deburring edge production line, equipment through linear processing, multiple groups of sand line wheel rotation, revolution, alternating, can truly uniform removal of parts surface, contour edge and hole edge burr and uniform chamfering.

In any cutting, drilling, laser, mill, and other machining processes, burrs, hot slag, and scum will be produced at the edge of

the workpiece, so it is particularly important to choose the correct deburring machine

the workpiece, so it is particularly important to choose the correct deburring machine

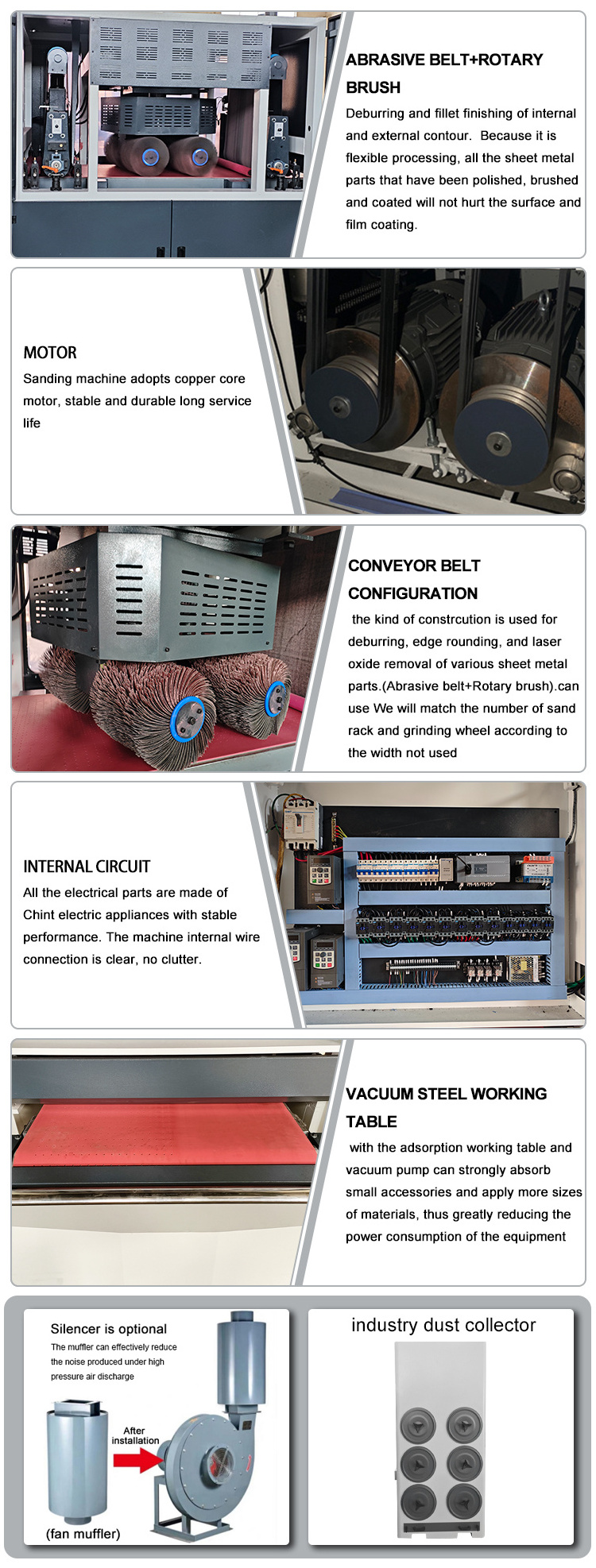

Features

1) Deburring and fillet finishing of internal and external contour. Because it is flexible processing, all the sheet metal parts

that have been polished, brushed and coated will not hurt the surface and film coating.

2) It is suitable for removing burrs in the holes of flat or relatively the same flat sheet metal parts processed by CNC punching

and shearing machines; Removal of burr after laser cutting; Flame cutting or plasma cutting slag removal.

3) Instead of burr, use file, scraper or electric and pneumatic tools for grinding process, so that the workpiece is polished more

evenly; Safer, and effectively reduce labor costs and improve production efficiency.

4) Visual adjustment of grinding and stroke parameters, can only grind the workpiece contour and sharp edge without damaging the

surface, effectively protect the coating of the workpiece, suitable for galvanized plate, coated aluminum plate, copper plate,

stainless steel plate and other surface requirements of the protection of the workpiece.

5) Turbo vacuum adsorption technology is adopted to ensure that the workpiece is firmly adsorbed during grinding, and the

workpiece and shaped workpiece can also be adsorbed and polished after bending, greatly improving the processing range and

efficiency, and preventing pressure loss or failure of the vacuum adsorption system due to blockage. More special magnetic suction

system, when the workpiece is conditional to use magnetic adsorption fixed, greatly reduce the power consumption of equipment,

energy saving and environmental protection, the maximum cost of production savings.

6) The equipment adopts Delta PLC control system, easy to operate, convenient to adjust the grinding amount.

7) If disk adsorption is selected for the product type, the power consumption of the device will be greatly reduced.

The machine uses common consumables in the market, and can also be customized imported sand wheel to improve production efficiencyand to meet the special requirements of products.

that have been polished, brushed and coated will not hurt the surface and film coating.

2) It is suitable for removing burrs in the holes of flat or relatively the same flat sheet metal parts processed by CNC punching

and shearing machines; Removal of burr after laser cutting; Flame cutting or plasma cutting slag removal.

3) Instead of burr, use file, scraper or electric and pneumatic tools for grinding process, so that the workpiece is polished more

evenly; Safer, and effectively reduce labor costs and improve production efficiency.

4) Visual adjustment of grinding and stroke parameters, can only grind the workpiece contour and sharp edge without damaging the

surface, effectively protect the coating of the workpiece, suitable for galvanized plate, coated aluminum plate, copper plate,

stainless steel plate and other surface requirements of the protection of the workpiece.

5) Turbo vacuum adsorption technology is adopted to ensure that the workpiece is firmly adsorbed during grinding, and the

workpiece and shaped workpiece can also be adsorbed and polished after bending, greatly improving the processing range and

efficiency, and preventing pressure loss or failure of the vacuum adsorption system due to blockage. More special magnetic suction

system, when the workpiece is conditional to use magnetic adsorption fixed, greatly reduce the power consumption of equipment,

energy saving and environmental protection, the maximum cost of production savings.

6) The equipment adopts Delta PLC control system, easy to operate, convenient to adjust the grinding amount.

7) If disk adsorption is selected for the product type, the power consumption of the device will be greatly reduced.

The machine uses common consumables in the market, and can also be customized imported sand wheel to improve production efficiencyand to meet the special requirements of products.

Production sepcitication

Product Paramenters

|

Working width(mm)

|

1300

|

|

Min.Working length(mm)

|

300

|

|

Working thickness(mm)

|

0-100

|

|

Abrasive belt motor(kw)

|

18.5

|

|

Rotary brush motor power(kw)

|

2.2X3

|

|

Total Power

|

44kw

|

|

Transmission motor power(kw)

|

4

|

|

Lift motor power

|

0.55

|

|

No.1 unit of belt shelf

|

210mm

|

|

Adsorption

|

11kw 2900RPM

|

|

Controller system

|

Delta PLC

|

|

Rotary brush size(mm)

|

300x300x25

|

|

Rotary brush quantity

|

6

|

|

Voltage

|

220v/380V3PH

|

|

Power

|

50/60HZ

|

|

Abrasive belt size(mm)

|

1320*2020mm

|

|

Overall dimensions(mm)

|

Machine :2700*2300*2100mm

Vacuum pump :1000*1000*2000mm |

|

Gross Weight(with wooden case)(kg)

|

3200KGS

|

Sample

1) The equipment adopts Delta PIC control system, easy to operate, digital monitoring grinding friction resistance, convenient and quick adjustment of grinding amount.

2) For products with magnetic capability, disk adsorption and fixation can be selected. The negative pressure adsorption system does not need to be opened, which will greatly reduce the power consumption of the device.

3) The machine uses common consumables in the market, without special customization or purchase by designated suppliers. The limitation of binding consumables to imported equipment or some domestic brand equipment is eliminated, which greatly reduces the user's use cost. (Size: 300-300-25, 80-120 mesh)

4) Sand line wheel can also be customized to improve production efficiency and meet the special requirements of products.

5) The equipment is equipped with a dust collector interface to absorb the dust, metal chips and dust generated in the working process of the equipment, and collect them uniformly in the dust collection box of the equipment to keep the working environment clean. The dust collector itself has the recoil function, which can automatically clean the filter element to prevent the dust removal failure caused by blockage (optional)

2) For products with magnetic capability, disk adsorption and fixation can be selected. The negative pressure adsorption system does not need to be opened, which will greatly reduce the power consumption of the device.

3) The machine uses common consumables in the market, without special customization or purchase by designated suppliers. The limitation of binding consumables to imported equipment or some domestic brand equipment is eliminated, which greatly reduces the user's use cost. (Size: 300-300-25, 80-120 mesh)

4) Sand line wheel can also be customized to improve production efficiency and meet the special requirements of products.

5) The equipment is equipped with a dust collector interface to absorb the dust, metal chips and dust generated in the working process of the equipment, and collect them uniformly in the dust collection box of the equipment to keep the working environment clean. The dust collector itself has the recoil function, which can automatically clean the filter element to prevent the dust removal failure caused by blockage (optional)

Packing&Transportation

Product Recommendation

Hot Searches