- Product Details

- {{item.text}}

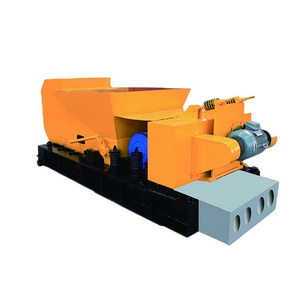

Quick Details

-

Brand Name:

-

SOKE

-

Voltage:

-

220V/380V

-

Power:

-

4KW

-

Dimension(L*W*H):

-

3300x3000x1200

-

Weight:

-

4500 kg

-

Features:

-

Concrete wall panel machine

-

Raw materials:

-

Concrete

-

Product name:

-

Lightweight Concrete Fence Molds For Sale Concrete Wall For Fence

-

Usage:

-

Precast Buildings

-

Advantages:

-

Easy Install

-

Type:

-

Semi-automation

-

Keywords:

-

Prefabricated Building Wall Panel Machine

-

Finished products:

-

Hollow Core Wall Panel

-

Wall panel Advantage:

-

Ligthweight

-

Wall panel Type:

-

Acotec Wall Panels

-

Use1:

-

Insulating Wall Panel

Quick Details

-

Application:

-

Prefab houses

-

Production Capacity:

-

100000m2/year

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SOKE

-

Voltage:

-

220V/380V

-

Power:

-

4KW

-

Dimension(L*W*H):

-

3300x3000x1200

-

Weight:

-

4500 kg

-

Features:

-

Concrete wall panel machine

-

Raw materials:

-

Concrete

-

Product name:

-

Lightweight Concrete Fence Molds For Sale Concrete Wall For Fence

-

Usage:

-

Precast Buildings

-

Advantages:

-

Easy Install

-

Type:

-

Semi-automation

-

Keywords:

-

Prefabricated Building Wall Panel Machine

-

Finished products:

-

Hollow Core Wall Panel

-

Wall panel Advantage:

-

Ligthweight

-

Wall panel Type:

-

Acotec Wall Panels

-

Use1:

-

Insulating Wall Panel

Lightweight wall panel machine description

Lightweight wall panel machine description

1. The lightweight wall panel machine using hydraulic opening and closing system.

2. Simple operation and high efficiency, low labor intensity.

3. The wall panel machine can also be equipped with vibrator system for thick mortar

4. The wall panel machine u sing Q235 steel, thickness 6-8mm, it will be welded on Horizontal worktable with pressing system to leveling tolerance ≤ The leveling tolerance after all the Q235 steel plates after assembling will be ≤3mm

5. The bottom steel plate for tongue,The aluminum part with plastic coating for tongue profile to guarantee the precision of tongue. The aluminum part will be fixed on 6mm steel plates.

6. Mound layer for top groove, The aluminum part with plastic coating for tongue profile to guarantee the precision of top groove

7. The Pipes, using steel pipes inside. PVC pipe fixed outside.

2. Simple operation and high efficiency, low labor intensity.

3. The wall panel machine can also be equipped with vibrator system for thick mortar

4. The wall panel machine u sing Q235 steel, thickness 6-8mm, it will be welded on Horizontal worktable with pressing system to leveling tolerance ≤ The leveling tolerance after all the Q235 steel plates after assembling will be ≤3mm

5. The bottom steel plate for tongue,The aluminum part with plastic coating for tongue profile to guarantee the precision of tongue. The aluminum part will be fixed on 6mm steel plates.

6. Mound layer for top groove, The aluminum part with plastic coating for tongue profile to guarantee the precision of top groove

7. The Pipes, using steel pipes inside. PVC pipe fixed outside.

Lightweight wall panel machine specification

Lightweight wall panel machine specification

Feature of lightweight wall panels

Feature of lightweight wall panels

Feature of lightweight wall panel

1. Light weight:

Its density is only 45-60 kg/m2 , and the weight of 75mm thick wall panel is 35kg/m2, which is only 1/7 of that of brick walls, 1/3 of that of aerated concrete, and 1/8 of that of 120mm thick masonry wall with plastering on both sides.

2. Fire proofness: It can endure fire at 1000 degrees for over 4 hours, without producing any toxic gas. Its incombustibility meets a rating of thestate standard.

3. Sound Insulation: It has outstanding sound absorption and insulation capacity. The sound insulation capacity of a 90mm thick board is 42dB, which is far higher than that of other masonry walls, and meet the national requirement of sound insulation for residential houses.

4. Thermal Insulation & Heat Insulation: Nowadays, the construction industry attaches great importance to energy-saving property of buildings. Ionic strip-type wall panel is made of pure natural vermiculite, quartz flour of high purity, inorganic fiber and plant fiber. In addition, the internal alveolate structure also contributes to its remarkable thermal insulation & heat insulation property.

5. Better earthquake resistance and overall stability: Assembled into a whole structure, wall panel has an impact resistant capacity which is 1.5 times as high as that of normal masonry walls. The earthquake resistance is tens of times higher than normal masonry walls, meeting the requirement for buildings to resist earthquake of up to 8 degrees.

6. Easy installation: The wall panel can be grooved freely, nailed directly or embedded with expansion bolts to hang heavy things, like A/C; The single-point hanging strength is over 45kg; In addition, the wall panel has a flat and smooth surface, which is compatible with tiles and wall paper as the finish.

2. Fire proofness: It can endure fire at 1000 degrees for over 4 hours, without producing any toxic gas. Its incombustibility meets a rating of thestate standard.

3. Sound Insulation: It has outstanding sound absorption and insulation capacity. The sound insulation capacity of a 90mm thick board is 42dB, which is far higher than that of other masonry walls, and meet the national requirement of sound insulation for residential houses.

4. Thermal Insulation & Heat Insulation: Nowadays, the construction industry attaches great importance to energy-saving property of buildings. Ionic strip-type wall panel is made of pure natural vermiculite, quartz flour of high purity, inorganic fiber and plant fiber. In addition, the internal alveolate structure also contributes to its remarkable thermal insulation & heat insulation property.

5. Better earthquake resistance and overall stability: Assembled into a whole structure, wall panel has an impact resistant capacity which is 1.5 times as high as that of normal masonry walls. The earthquake resistance is tens of times higher than normal masonry walls, meeting the requirement for buildings to resist earthquake of up to 8 degrees.

6. Easy installation: The wall panel can be grooved freely, nailed directly or embedded with expansion bolts to hang heavy things, like A/C; The single-point hanging strength is over 45kg; In addition, the wall panel has a flat and smooth surface, which is compatible with tiles and wall paper as the finish.

Installation Instructions

Installation Instructions

Advanatage of using lightweight concrete wall panel for wall construction

The speed of construction and labor-saving:

3 workers can build a wall of 15m2 in 1 hour.

Saving of mortar: the mortar needed for works is just 20-25% compared to using traditional brick and 40-50% compared to using AAC of CLC blocks.

Easy of installation: electric and communication cables, pipelines can be installed much easier, cheaper and faster.

Lower construction costs: the final cost to build 1m2 of a wall by SOKE concrete panels is 40-50% lower compared to clay bricks wall or 70-75% lower compared to AAC/CLC blocks wall. This brings an enormous saving and profit to the investor (not to mention the cost savings from early completion of the project and about 30% reduction of the foundation cost thanks to the light weight of the wall).

Energy savings: SOKE lightweight wall panels are suitable for high-rise buildings construction. It helps to save energy bill by reducing the cost of air conditioning, heating due to great heat & sound insulations.

Saving of mortar: the mortar needed for works is just 20-25% compared to using traditional brick and 40-50% compared to using AAC of CLC blocks.

Easy of installation: electric and communication cables, pipelines can be installed much easier, cheaper and faster.

Lower construction costs: the final cost to build 1m2 of a wall by SOKE concrete panels is 40-50% lower compared to clay bricks wall or 70-75% lower compared to AAC/CLC blocks wall. This brings an enormous saving and profit to the investor (not to mention the cost savings from early completion of the project and about 30% reduction of the foundation cost thanks to the light weight of the wall).

Energy savings: SOKE lightweight wall panels are suitable for high-rise buildings construction. It helps to save energy bill by reducing the cost of air conditioning, heating due to great heat & sound insulations.

Uses and application of lightweight concrete wall panels

Uses and application of lightweight concrete wall panels

Our services

Our services

* The technical supporting all the time 7x24hours

* One year warranty for whole machine

* Free quick wear parts

* Free training to end-users and online training

* Low charge continue maintenance

* One year warranty for whole machine

* Free quick wear parts

* Free training to end-users and online training

* Low charge continue maintenance

Contact US

Contact US

Whatsapp:+8615589991532

Wechat:evansoke

SOKE INTERNATIONAL(Precast Machine Department)

Contact person:Evan

M:+ 86 15589991532

WhatsApp/Wechat: + 86 15589991532

Website: www.sokeprecastmachine.com

M:+ 86 15589991532

WhatsApp/Wechat: + 86 15589991532

Website: www.sokeprecastmachine.com

We welcome you to consult our precast concrete hollow core slab machine, Foam Concrete Concrete Fence Molds For Sale Concrete Wall For Fence,concrete Beam machine, concrete lintel machine, concrete H beam machine, concrete T beam machine or other equipments related precast technology.

Hot Searches