HYDRAULIC PRESS STATION

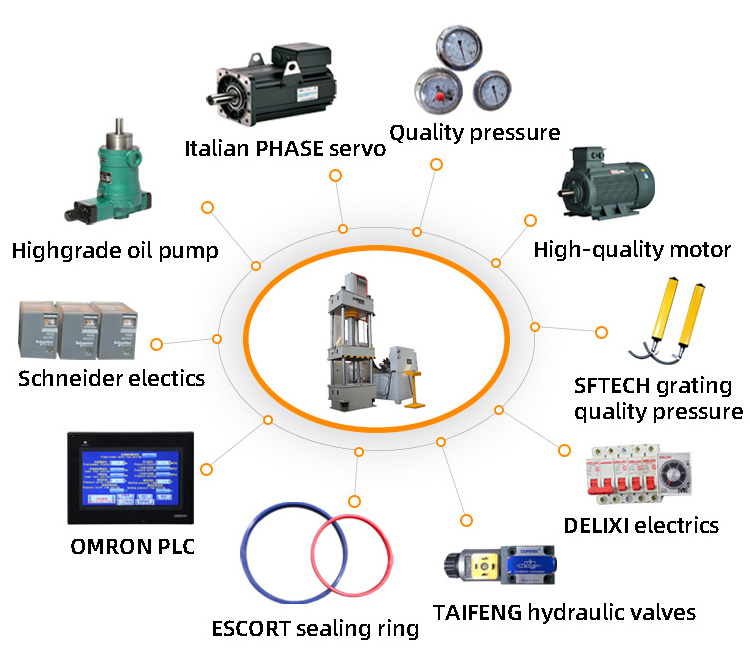

Hydraulic integrated system adopts independent control unit.

Convenient maintenance.