- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

400 mm

-

Width of Working Table (mm):

-

120 mm

-

Dimension:

-

3800*2100*3050

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BLMA

-

Weight (KG):

-

14500

-

Motor Power (kw):

-

18.5 kw

-

Product name:

-

Hydraulic Cnc Bending Machine

-

Application:

-

Sheet Metal Bending

-

Main power:

-

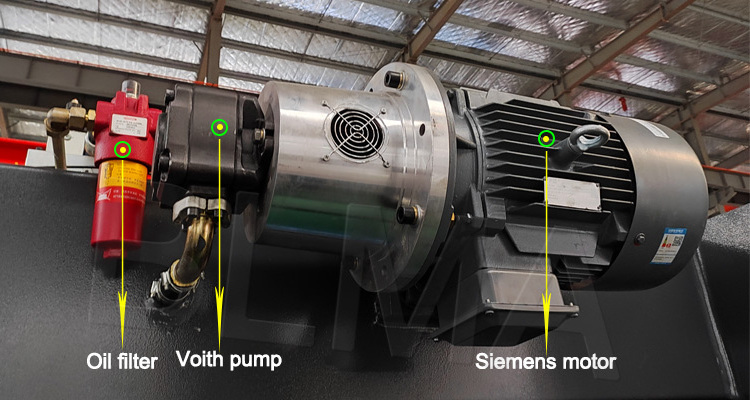

Siemens, Germany

-

Gasket ring:

-

VALQUA, Japan

-

Valve:

-

Rexroth, Germany

-

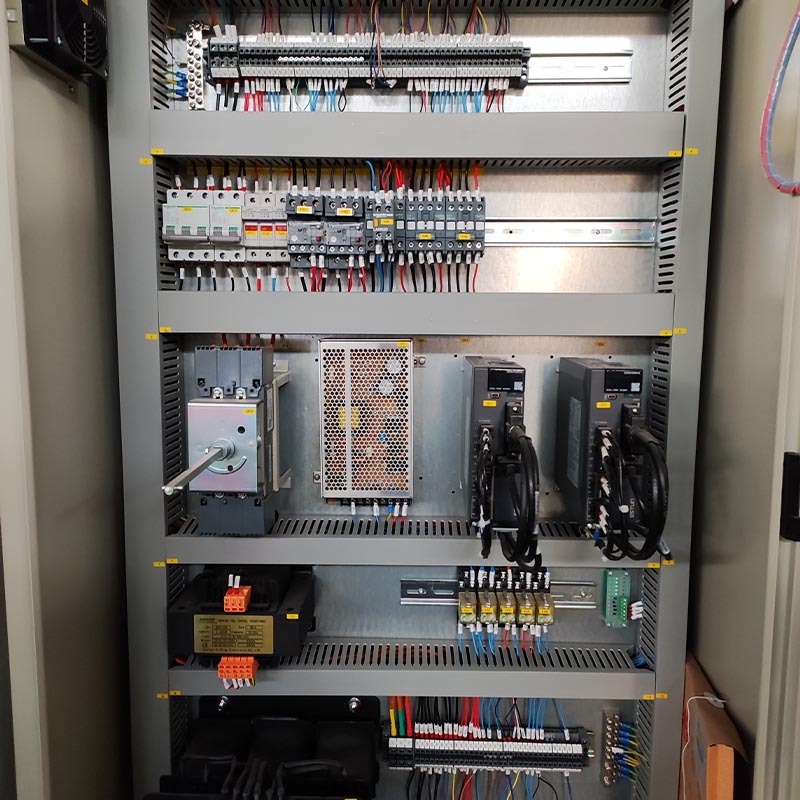

Electronics:

-

Schneider, France

-

Voltage:

-

220V/380V/415V/440V/customized

-

Keyword:

-

servo press brake

-

CNC or not:

-

CNC Bender Machine

-

Certification:

-

ce

Quick Details

-

Machine Type:

-

Synchronized

-

Length of Working Table (mm):

-

4000

-

Slider Stroke (mm):

-

200 mm

-

Throat Depth (mm):

-

400 mm

-

Width of Working Table (mm):

-

120 mm

-

Dimension:

-

3800*2100*3050

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BLMA

-

Weight (KG):

-

14500

-

Motor Power (kw):

-

18.5 kw

-

Product name:

-

Hydraulic Cnc Bending Machine

-

Application:

-

Sheet Metal Bending

-

Main power:

-

Siemens, Germany

-

Gasket ring:

-

VALQUA, Japan

-

Valve:

-

Rexroth, Germany

-

Electronics:

-

Schneider, France

-

Voltage:

-

220V/380V/415V/440V/customized

-

Keyword:

-

servo press brake

-

CNC or not:

-

CNC Bender Machine

-

Certification:

-

ce

Products Description

The fuselage adopts integral welding and integral processing structure. The main components of the fuselage are analyzed by ANSYS finite element analysis software to ensure the reliability and accuracy of the fuselage.

Adopting the closed-loop control method composed of German electro-hydraulic servo valve and grating ruler, the slider position feedback accuracy is high, the operation is accurate and stable, the synchronization performance is good, and the bending accuracy is high.

The numerical control system can realize the functions of bending angle graphic programming, angle correction compensation,automatic calculation and automatic adjustment of bending pressure, automatic calculation of the deformation compensation amount of the worktable, the unfolded length of the work piece, and the automatic back gauge of the back gauge.

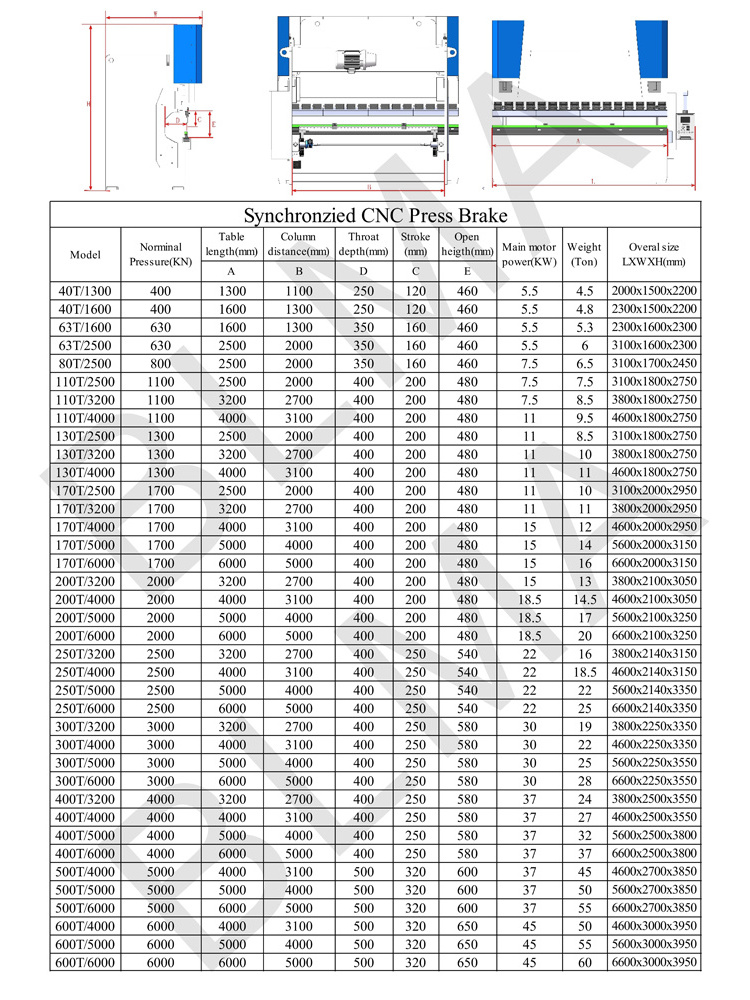

Product Paramenters

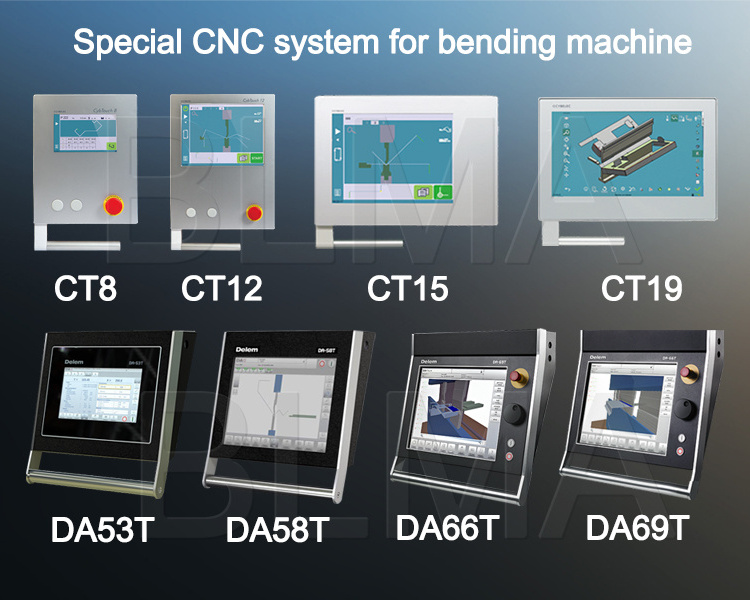

System

Machine details

Our Factory

Exhibition&Customer visit

Our services

Pre-service

1.We will help you confirm the model of our machine according to your offered pipe information.

1.We will help you confirm the model of our machine according to your offered pipe information.

2.You are very welcome to see our machine how to work in the factory before you place an order with us.

Aftersales-service:

1. Our machine is easy to use. Operation manual and teaching video will be sent out with machine.

Aftersales-service:

1. Our machine is easy to use. Operation manual and teaching video will be sent out with machine.

We also offer free training in our factory, the following is our training contents:

Detailed function of our machine, 1 hour;

NC control using, 0.5 hour;

Tooling installation and adjustment, 0.5-1 hours;

Maintenance and repair, 0.5-1 hours;

Real operation according client products, 1-2 hours.

During the training period,we offer free pick-up,hotel and food.

2. We guarantee machine quality for 13 months, during this period, if spare parts of the machine are not man-made damage, we can send the component to the customer by DHL, TNT freely.

2. We guarantee machine quality for 13 months, during this period, if spare parts of the machine are not man-made damage, we can send the component to the customer by DHL, TNT freely.

3.Our factory provide the service for the customer forever, if the customer need operation help,we provide 24 hours on-line reply service.

Hot Searches