Thank you so much.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

circle busbar punching dies

-

Product:

-

Industrial Parts

-

Product name:

-

Punching Molds

-

Material:

-

Metal

-

Usage:

-

punching

-

Shape:

-

Circle

-

Size(diameter):

-

7,9,11,13,17

-

Processing material:

-

Copper aluminum bus bar

-

Color:

-

Customized Color

-

MOQ:

-

1 Set

Quick Details

-

Warranty:

-

3 months

-

Place of Origin:

-

Zhejiang, China, Zhejiang,China

-

Brand Name:

-

Zhongyan

-

Model Number:

-

circle busbar punching dies

-

Product:

-

Industrial Parts

-

Product name:

-

Punching Molds

-

Material:

-

Metal

-

Usage:

-

punching

-

Shape:

-

Circle

-

Size(diameter):

-

7,9,11,13,17

-

Processing material:

-

Copper aluminum bus bar

-

Color:

-

Customized Color

-

MOQ:

-

1 Set

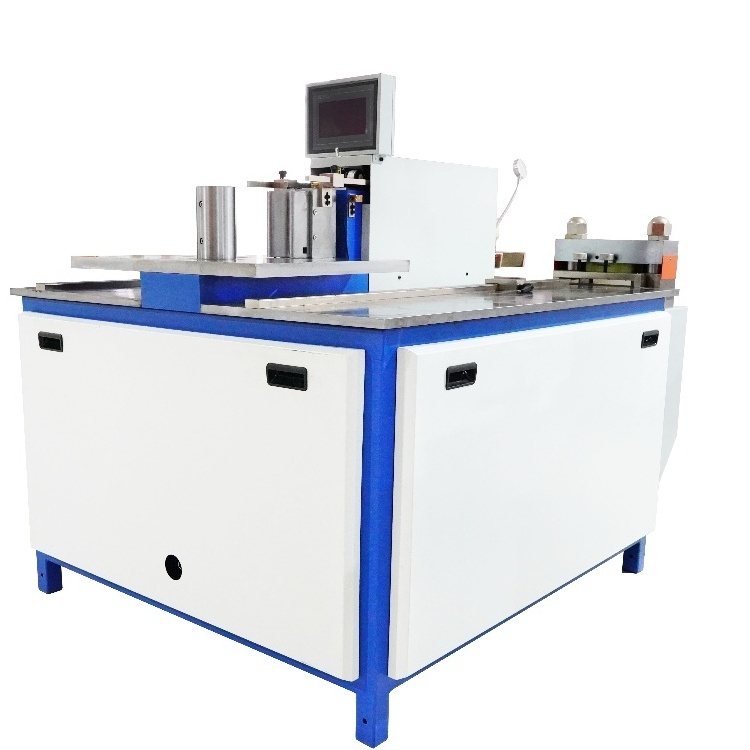

Mainly for this type of bus machine.

If you are not sure which bus machine you have, please feel free to contact us before purchasing!

|

Place of Origin

|

China

|

|

Product

|

Industrial Parts

|

|

Product Name

|

Punching Molds

|

|

Application

|

Punching hole

|

|

Product Material

|

Metal

|

|

Processing material

|

Copper aluminum bus bar

|

|

Shape

|

Circle

|

|

Size

|

Φ7

|

One machine and three stations are synchronized in one, and can be used independently at the same time. There is no waste after cutting at the cutting station. The high-precision five-arm punching die set has its own light source positioning and scale positioning. Double-cylinder blanking device, smooth punching waste discharge , Digital ruler is equipped with proximity switch device, large and small bending station pressure adjustment, manual and numerical control can be freely converted, the bending angle is simple and convenient.

This busbar processing machine is mainly used for the processing of copper and aluminum busbars of various high and low voltage power transmission and distribution complete sets of electrical and power transformers. It is used for cutting, punching, bending, bending, and other processes of copper and aluminum busbars. Various molds such as shearing, punching, PLC program-controlled bending, vertical bending, pressing pitting, flat pressing, and pressing cable joints can be interchanged independently in the workstation, and the matching specifications are optional.

It is mainly used to handle various types of copper and aluminum strips, such as high and low voltage switchgear, substations, transformers, electrical switches, chassis cabinets, large bus pipes, etc.

1.

Can I get a machine according to my own requirements?

Sure. We can change the type and color and appearance of the machine according to your preferences and requirements, so that we can satisfy you.

2.

What's the quality of your machine?

Our machine adopts heavy lathe bed, and each part is processed by fine machining, which greatly improves the accuracy of machine operation.

3.

What is your power supply?

We could customized it according to your countries power supply.

4. What is your Min order quantity?

One set.

5.

What’s the delivery time, and what’s the package?

Normally the delivery time is about 30-45 days. All our CNC machines are packed with seaworthy package.

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for

producing PET plastic containers and bottles in all shapes.

producing PET plastic containers and bottles in all shapes.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hot Searches