- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

injection molding-070

-

Years in industry:

-

13

-

English Speaker:

-

15

-

Engineers:

-

6

-

Injection Machines:

-

26

-

Biggest Part Size:

-

1500*1500*1000mm

-

Biggest Part Weight:

-

5800g

-

Tolerance:

-

0.01mm

-

Colors Available:

-

Pantone/RAL and other custom colors

-

Surface Finish:

-

Testure/Sand/MT/YS/SPI

-

Drawing Format:

-

STEP/STP/IGS/X-T/STL/CAD/PDF/DWG and Other

Quick Details

-

Processing Service:

-

Moulding

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Zetar

-

Model Number:

-

injection molding-070

-

Years in industry:

-

13

-

English Speaker:

-

15

-

Engineers:

-

6

-

Injection Machines:

-

26

-

Biggest Part Size:

-

1500*1500*1000mm

-

Biggest Part Weight:

-

5800g

-

Tolerance:

-

0.01mm

-

Colors Available:

-

Pantone/RAL and other custom colors

-

Surface Finish:

-

Testure/Sand/MT/YS/SPI

-

Drawing Format:

-

STEP/STP/IGS/X-T/STL/CAD/PDF/DWG and Other

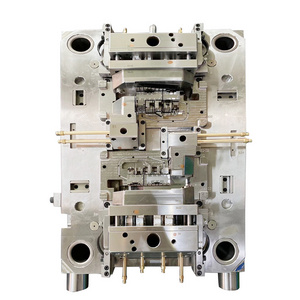

China Mold Manufacturer Professional Plastic Injection Molding Factory

|

Mold Material

|

45#,P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, etc .

|

|

Mold Type

|

Plastic Injection Molding

|

|

Product Material

|

ABS, PA, PA66+GF, POM, PC, PP, PET, TPE, PVC, HDPE, etc

|

|

Mold Standard

|

HASCO, DME, MISUMI, JIS, LKM, etc.

|

|

Mold Tooling Equipment

|

Lathe,Milling,Grinder,Drill,CNC,EDM,Wire cut machine,Punch machine

|

|

Injection Mold Machine

|

19 Sets With Model 90T to 1100T

|

|

Gate Type

|

Side Gate, Sub Gate, Direct Gate, Hook Gate, Pin Point Gate, etc.

|

|

Runner Type

|

Cold Runner or Hot Runner

|

|

Cavity

|

Single or Multi cavities

|

|

Mold Life

|

45#:50,000 to 100,000 shots

P20:100,000 to 200,000 shots

718: 200,000 to 300,000 shots

H13: 300,000 to 500,000 shots

|

|

Lead Time

|

Generally mold making will take around 30 days and 7-10 day to mass production

|

|

Package

|

Wooden packing box for molds and Generally inner packed in opp bags, outside packed in standard export carton with shipping marks,

and the cartons will be full of bubble bags. |

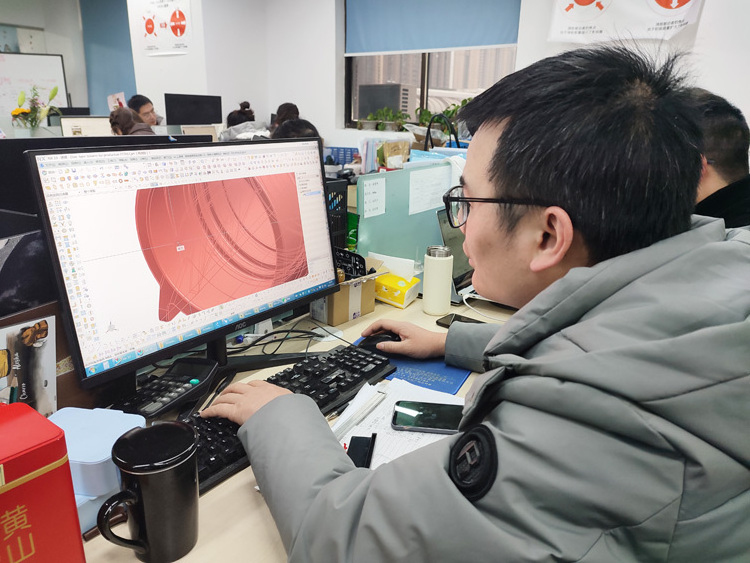

Shanghai Zetar Industry Co., Limited has been focus on plastic injection mold and molding serivce ever since its fundation.

We have professional engineering team which has more than 5 engineers who is good at plastic injection mold design, plastic injection molding process as well as metal stamping works.

Our company has In-house tooling shop- fully equipped 6000 square feet tool room,making sure your molds making in house,providing free mold routine maintenance,and also mold repair work if you need.

Meanwhile 90 ton - 1100 ton injection molding machines 20 sets,30000 square feet injection molding room including 250 square feet M7 class clean room.We can produce parts from 0.01pound to 13 pounds.

Sales team are thoughtful and good at understanding your idea and points, where help to make your work much eaiser. 24*7 comminication service, whenever you need us, we are here for you.

Morever, we stand at your position, practice strict quality inspection procedures.

Your satifaction is what we pursue.

We are a manufacturer as you can see our workshop as above.

2. What kind of trade terms can you do?

EX-WORKS,FOB,CIF,DDP DDU

3. What is your terms of payment?

50% Mold cost deposit,balance mold cost +50% production cost paid when samples confimed,Balance production cost paid against copy

of B/L. We accept T/T

4. Do you support OEM ?

Yes, we can produce by technical drawings or samples.

5. How about your delivery time?

Generally, it take 40 days ( 30 days do mold and 10 days do mass production).