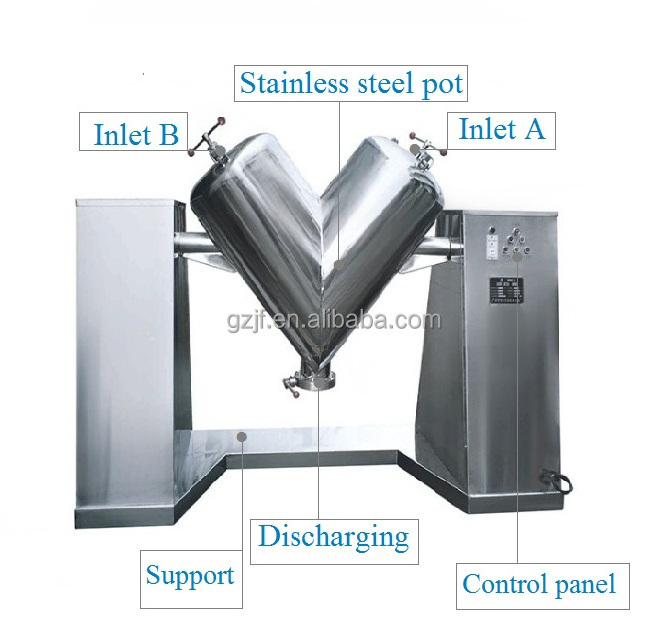

This machine can be used for uniform mixing of dry powdery or granular materials with good fluidity, and there is no dissolution, volatilization or deterioration of materials during the mixing process. Compared with ordinary mixers, this machine has reasonable

design, high mixing efficiency and simpler operation. The mixing cylinder has a unique structure, high mixing efficiency, no dead

angle, the cylinder is made of stainless steel, the inner and outer walls are polished, the appearance is beautiful, the mixing is uniform, and it has a wide range of uses, which meets the GMP standard. It can also be equipped with a forced agitator according to customer requirements, which is suitable for mixing finer powder and bulk materials with a certain amount of moisture.