- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

XT-Y31X

-

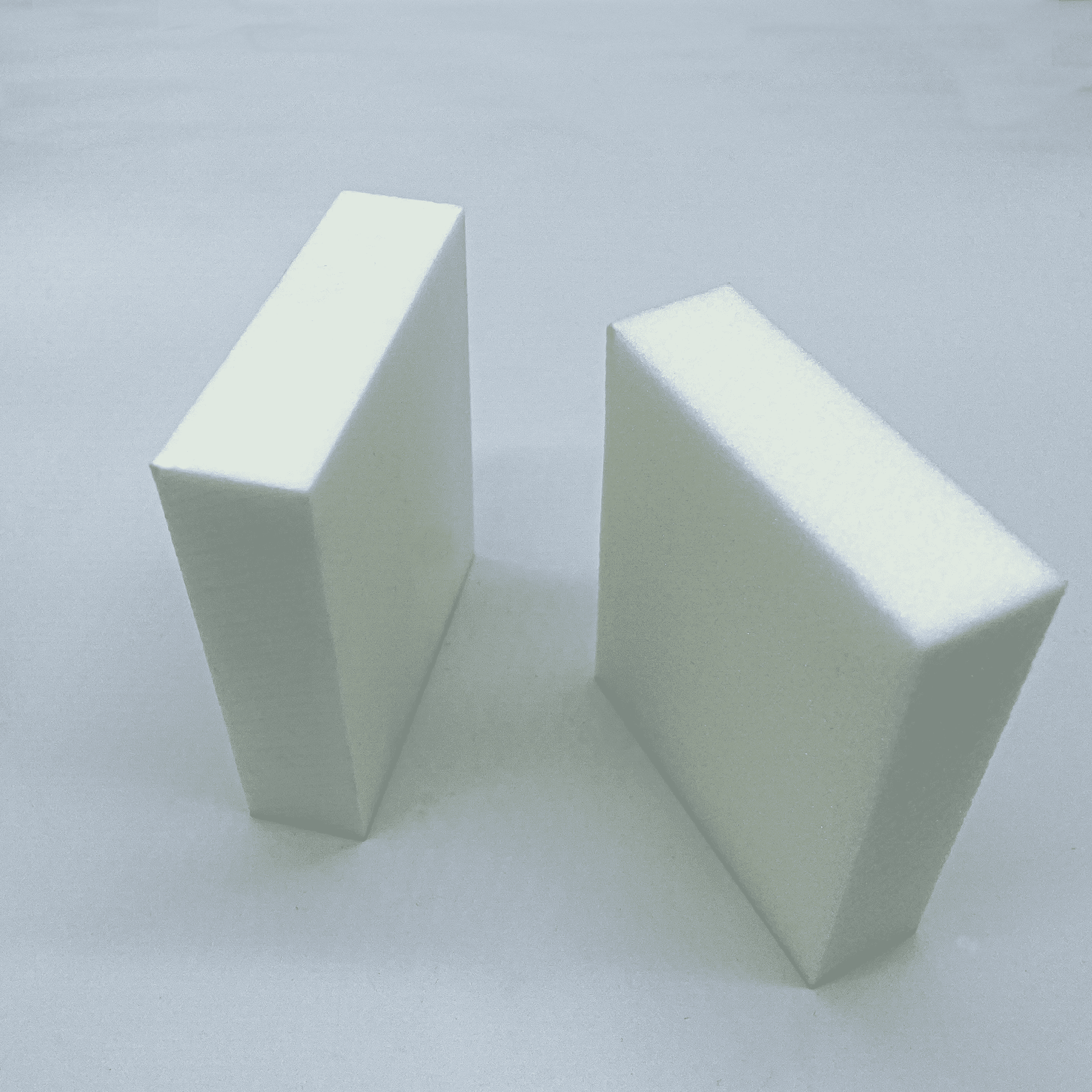

Thickness:

-

40-90mm

-

Size:

-

2500*1200*90mm

-

Product Name:

-

PMI foam core

-

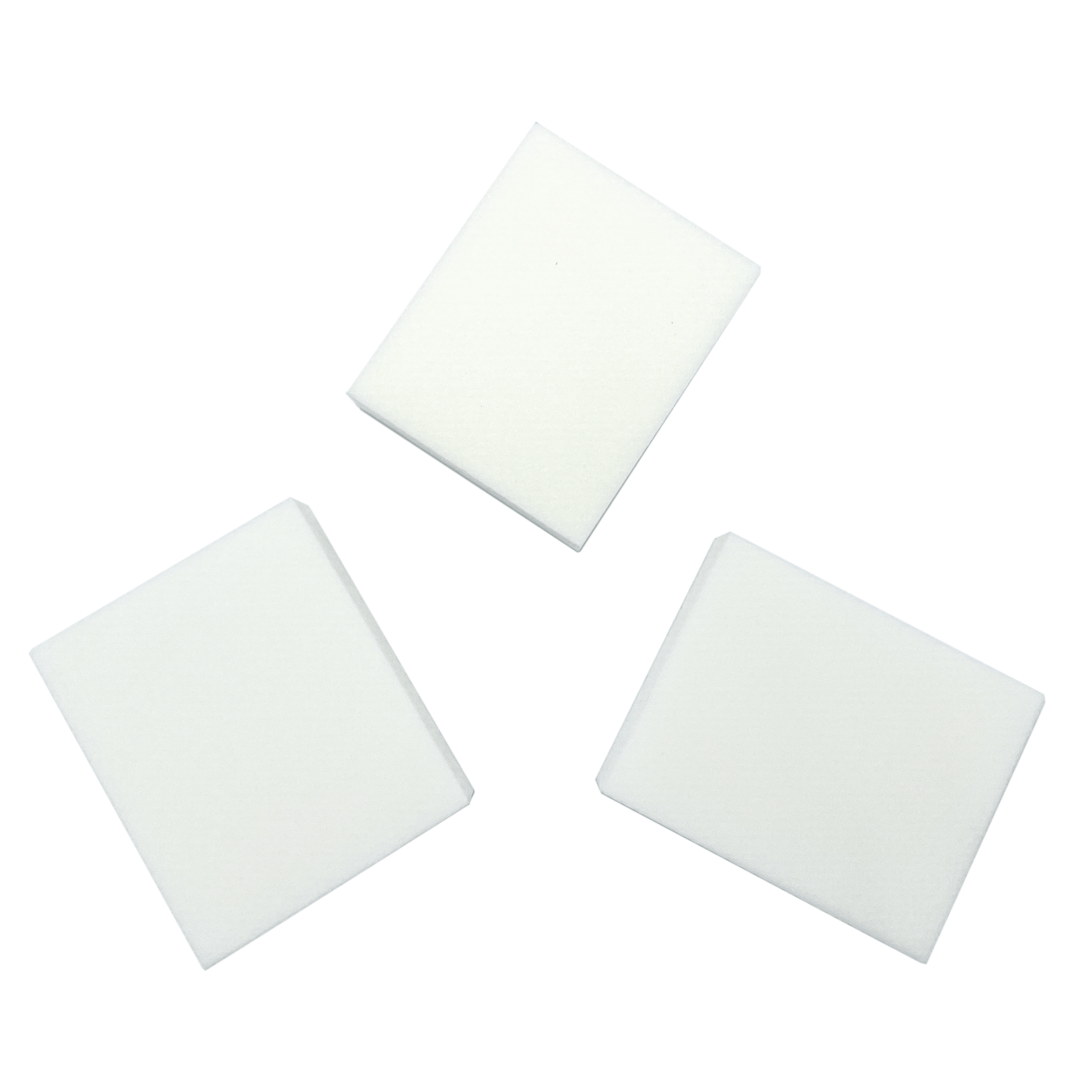

Color:

-

White

-

Feature:

-

Superior Strength and Low Density

-

Package:

-

Wooden case

Quick Details

-

Processing Service:

-

Cutting, Moulding

-

Place of Origin:

-

China

-

Brand Name:

-

Xintan

-

Model Number:

-

XT-Y31X

-

Thickness:

-

40-90mm

-

Size:

-

2500*1200*90mm

-

Product Name:

-

PMI foam core

-

Color:

-

White

-

Feature:

-

Superior Strength and Low Density

-

Package:

-

Wooden case

Product Description

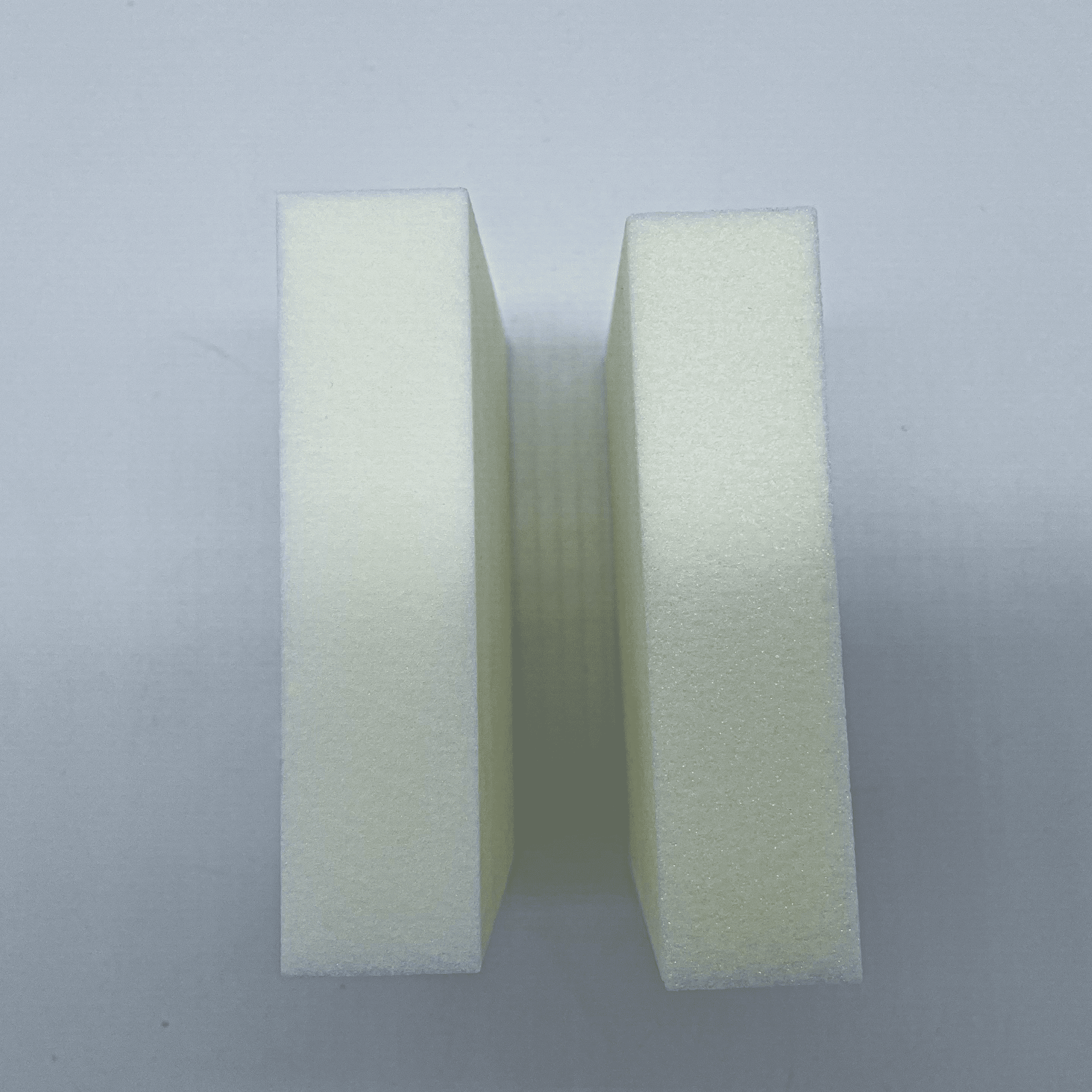

PMI foam is a high-performance polymeric structural foam produced by foaming and crosslinking raw materials such as MAA(methacrylic acid), MAN (maleic anhydride), and AN (acrylonitrile) at elevated temperatures. It is renowned for being one of the most advanced structural foam materials available today, offering superior comprehensive performance.

Product Paramenters

|

Model

|

Density (Typical)

|

Compression Strength

|

Cell Size

|

Standard Sheet Size

|

|

XT-Y31X

|

30kg/m3

|

0.9MPa

|

0.2~0.4mm

|

≥2500×1200×90mm

|

|

XT-Y350X

|

350kg/m3

|

15MPa

|

0.05~0.2mm

|

≥800×800×40mm

|

|

XT-Y40F

|

40kg/m3

|

1.2MPa

|

<0.1mm

|

≥2500×1200×85mm

|

|

XT-Y52R

|

50kg/m3

|

1.3MPa

|

0.2~0.4mm

|

≥2500×1200×80mm

|

|

XT-Y52H

|

50kg/m3

|

1.7 MPa

|

0.2~0.4mm

|

≥2500×1200×80mm

|

Product Advantages

PMI foam exhibits excellent thermal stability, capable of withstanding temperatures up to 180°C without deformation. Additionally, it is non-combustible and will self-extinguish when removed from a flame, enhancing safety in high-temperature environments.

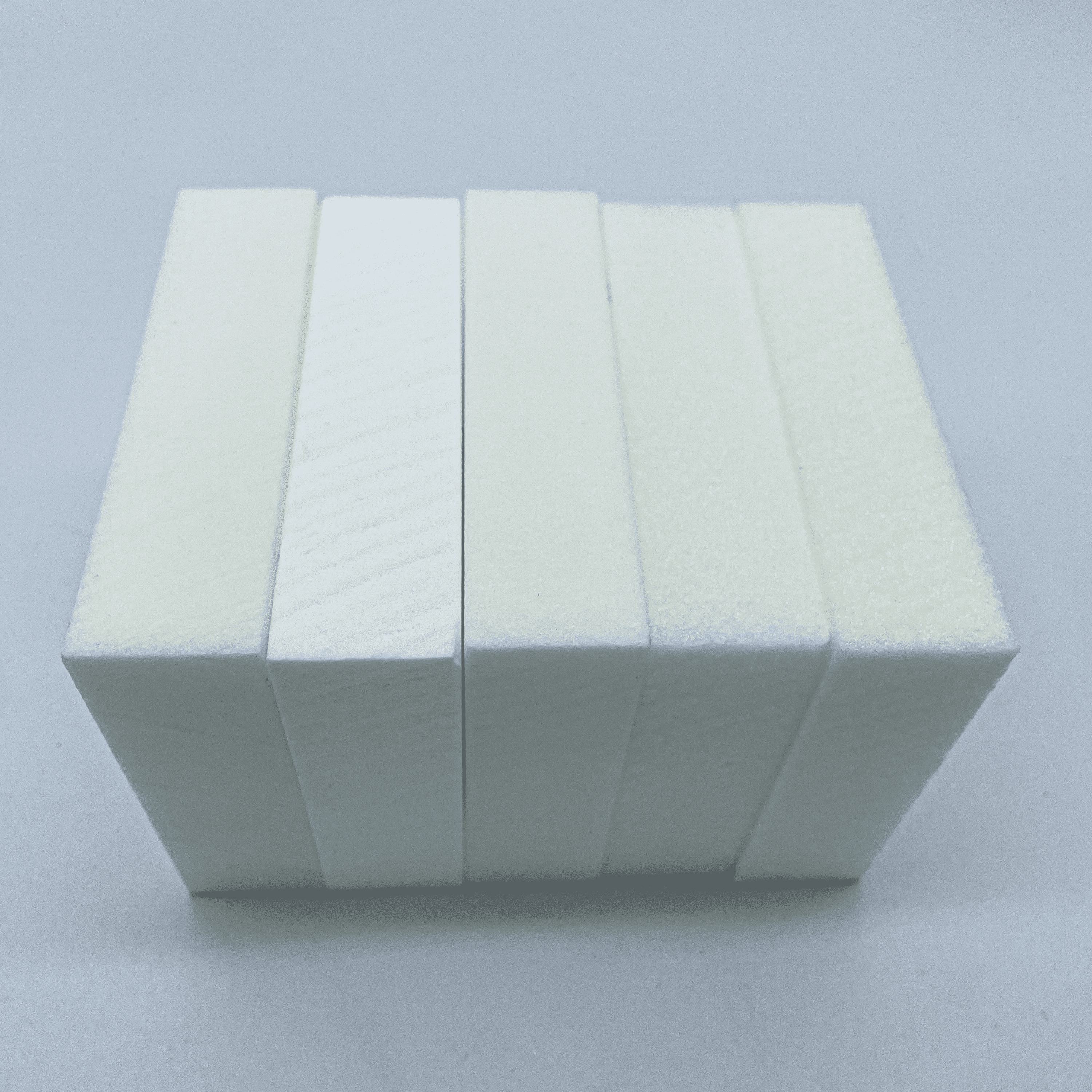

Despite its low density, PMI foam offers exceptional mechanical strength. This makes it suitable for applications requiring materials that are both lightweight and strong. The foam’s high surface quality further ensures durability and longevity in various applications.

Given its unique combination of lightweight properties, high thermal resistance, and superior mechanical strength, PMI foam is widely used in aerospace, automotive, construction, and other industries where advanced materials are essential for performance

and efficiency.

and efficiency.

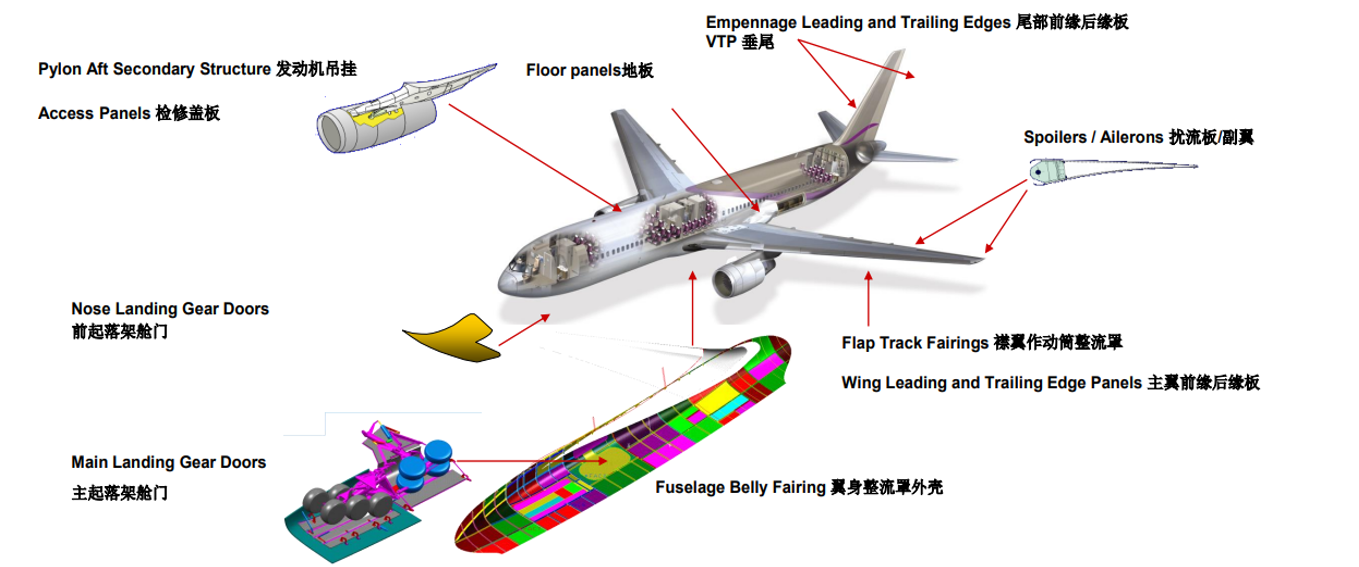

Applications

Aerospace Industry

In the aerospace industry, weight reduction is critical for improving fuel efficiency and overall performance. PMI foam's extremely low density, which can be as light as 30 kg/m³, makes it an ideal core material for sandwich structures in aircraft components. It is used in the construction of aircraft fuselages, wings, and other structural elements where both strength and weight savings are paramount. Additionally, PMI foam's ability to withstand high temperatures up to 180°C without deforming ensures it performs reliably in the demanding environments encountered during flight.

In the aerospace industry, weight reduction is critical for improving fuel efficiency and overall performance. PMI foam's extremely low density, which can be as light as 30 kg/m³, makes it an ideal core material for sandwich structures in aircraft components. It is used in the construction of aircraft fuselages, wings, and other structural elements where both strength and weight savings are paramount. Additionally, PMI foam's ability to withstand high temperatures up to 180°C without deforming ensures it performs reliably in the demanding environments encountered during flight.

Automotive Industry

The automotive industry also benefits from the use of PMI foam in various applications. As manufacturers strive to produce lighter vehicles to enhance fuel efficiency and reduce emissions, PMI foam offers an excellent solution for lightweighting. It is used in the construction of body panels, interior components, and structural reinforcements. The high mechanical strength of PMI foam ensures that these components can endure the stresses and strains of daily use while maintaining vehicle safety standards. Moreover, its non-combustible nature adds an extra layer of safety to automotive designs.

The automotive industry also benefits from the use of PMI foam in various applications. As manufacturers strive to produce lighter vehicles to enhance fuel efficiency and reduce emissions, PMI foam offers an excellent solution for lightweighting. It is used in the construction of body panels, interior components, and structural reinforcements. The high mechanical strength of PMI foam ensures that these components can endure the stresses and strains of daily use while maintaining vehicle safety standards. Moreover, its non-combustible nature adds an extra layer of safety to automotive designs.

In the construction sector, PMI foam is valued for its durability and thermal insulation properties. It is used in the fabrication of structural insulated panels (SIPs) and other composite materials that require a balance of strength and lightness. PMI foam's high surface quality contributes to the longevity and aesthetic appeal of construction elements, while its thermal stability makes it suitable for use in environments that experience significant temperature fluctuations. This material helps improve energy efficiency in buildings by providing effective insulation.

Sporting Goods

The sporting goods industry takes advantage of PMI foam's properties for creating high-performance equipment. It is used in the manufacture of lightweight, strong, and durable components in items such as helmets, protective gear, and sports equipment. Athletes benefit from the reduced weight of their gear without compromising on safety and performance.

The sporting goods industry takes advantage of PMI foam's properties for creating high-performance equipment. It is used in the manufacture of lightweight, strong, and durable components in items such as helmets, protective gear, and sports equipment. Athletes benefit from the reduced weight of their gear without compromising on safety and performance.

Medical Devices

In the medical field, PMI foam's biocompatibility and structural properties make it suitable for various applications, including prosthetics and orthotics. The foam's ability to be molded into complex shapes while maintaining strength ensures that medical devices are both functional and comfortable for patients.

In the medical field, PMI foam's biocompatibility and structural properties make it suitable for various applications, including prosthetics and orthotics. The foam's ability to be molded into complex shapes while maintaining strength ensures that medical devices are both functional and comfortable for patients.

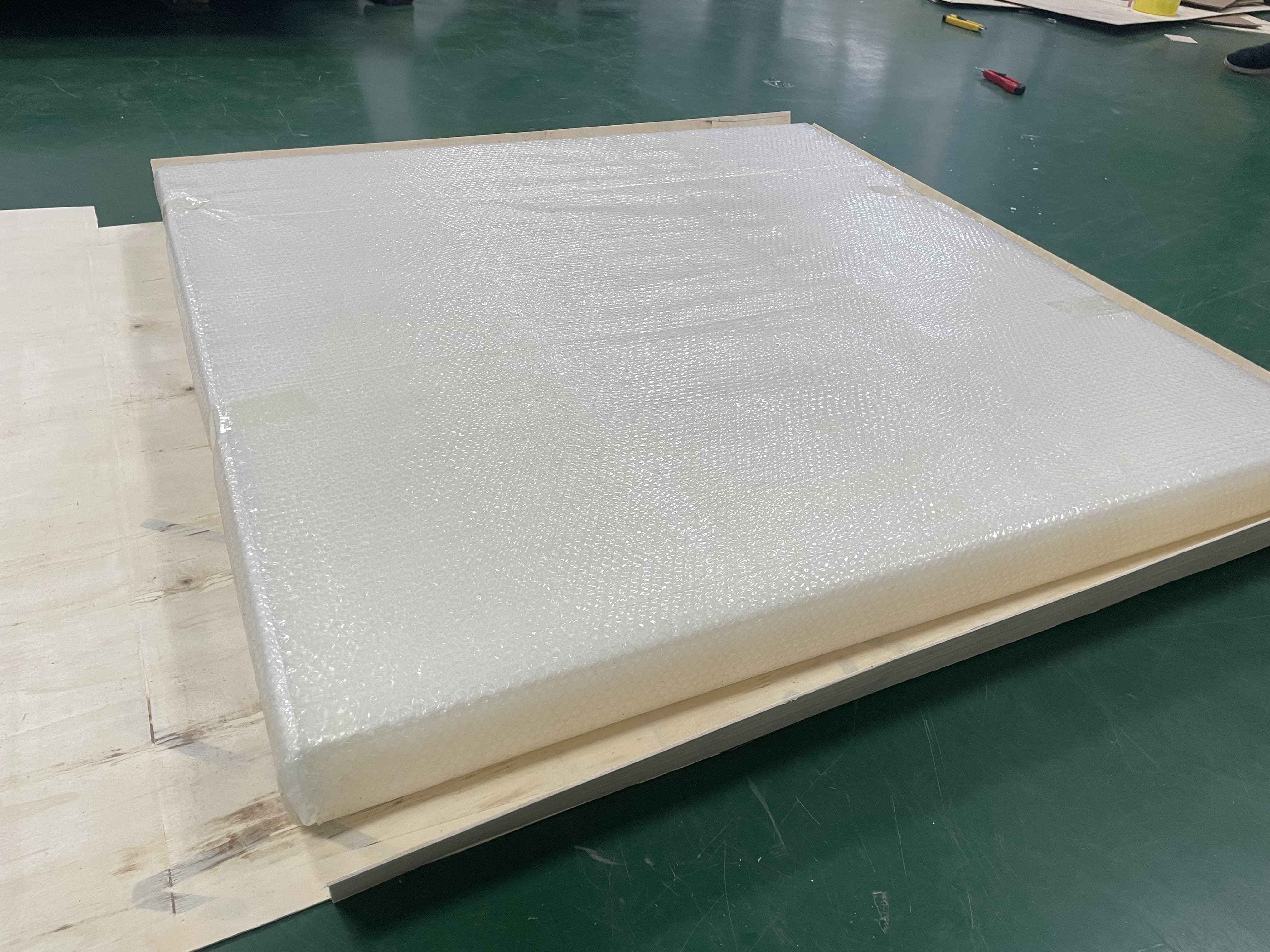

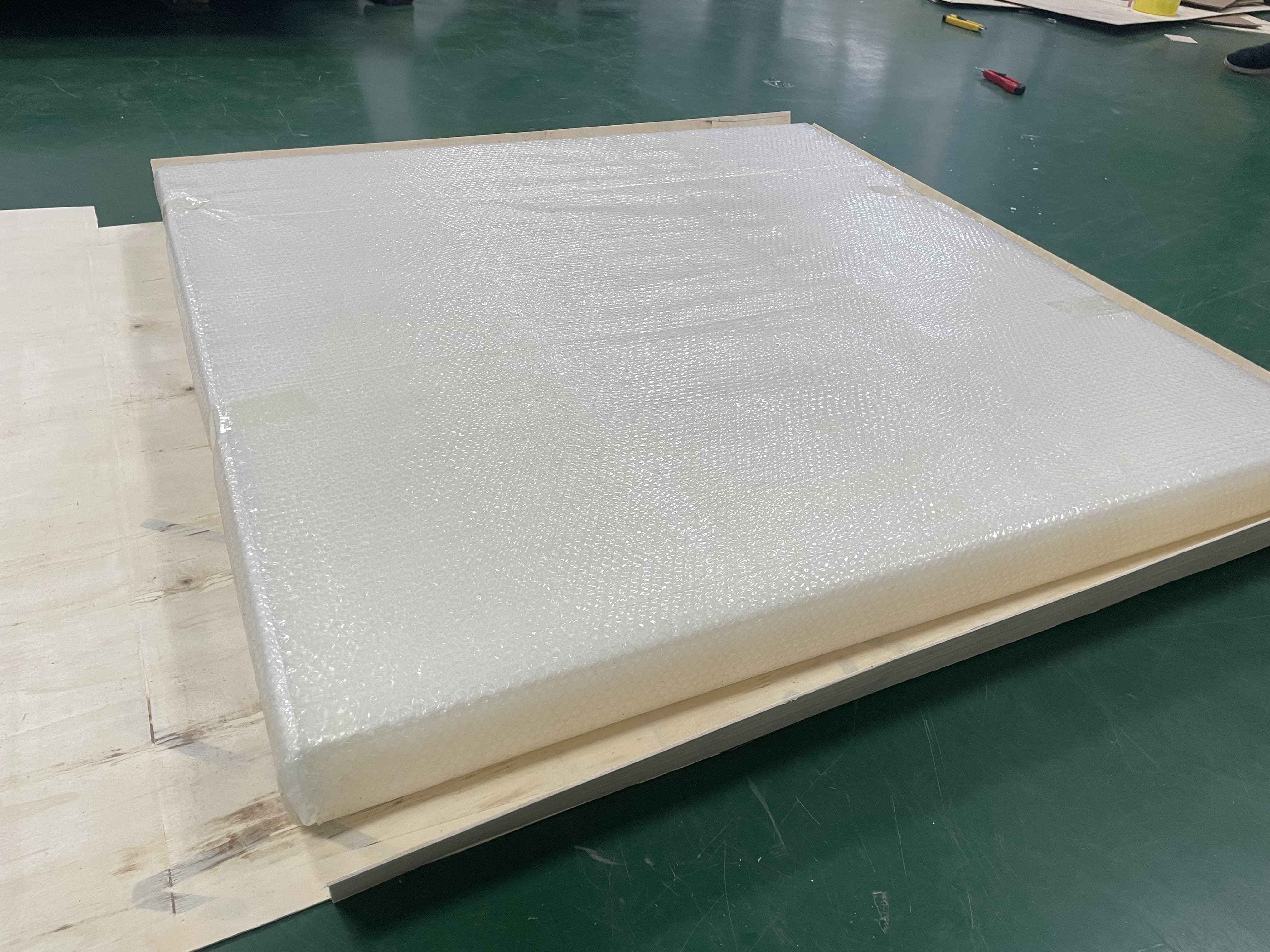

Product packaging

1. Packed by wood case or carton. Keep it in dry place

2. Include all necessary shipping and product documentation inside the package or in a clear, waterproof pouch attached to the outside.

Technical Support

The versatility and superior performance of PMI foam make it an indispensable material across these industries and more. We welcome any inquiries regarding PMI foam and its applications. Our team is ready to provide further information and assist with your specific needs. Please feel free to reach out to us at any time.

By choosing PMI foam, you are leveraging a material that combines innovation, efficiency, and reliability, tailored to meet the demands of advanced engineering applications.

Hot Searches