- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customers request, 380V/50HZ

-

Dimension(L*W*H):

-

3*5*4m, 3500*3200*2800mm

-

Year:

-

2023

-

Weight (KG):

-

1200 kg, 17500

-

Power (kW):

-

200, 75 kW

-

Application:

-

Rubber Powder Production Line

-

Oprerator:

-

2-4 persons

-

Supply Ability:

-

20 Set/Sets per Month

Quick Details

-

Place of Origin:

-

HENAN, Henan, China

-

Brand Name:

-

henan

-

Model Number:

-

400/600/800/1000/1200/1400/1600/1800

-

Voltage:

-

Customers request, 380V/50HZ

-

Dimension(L*W*H):

-

3*5*4m, 3500*3200*2800mm

-

Year:

-

2023

-

Weight (KG):

-

1200 kg, 17500

-

Power (kW):

-

200, 75 kW

-

Application:

-

Rubber Powder Production Line

-

Oprerator:

-

2-4 persons

-

Supply Ability:

-

20 Set/Sets per Month

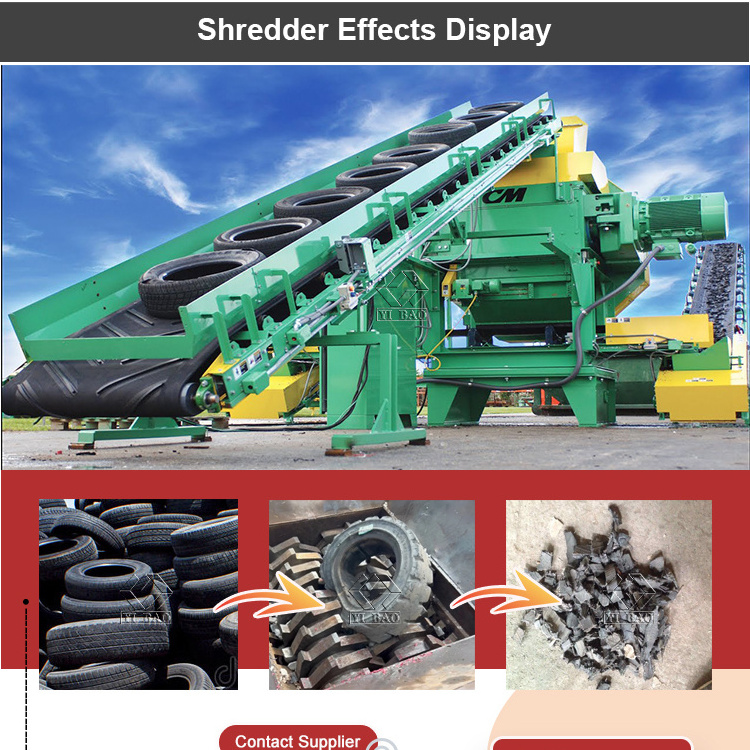

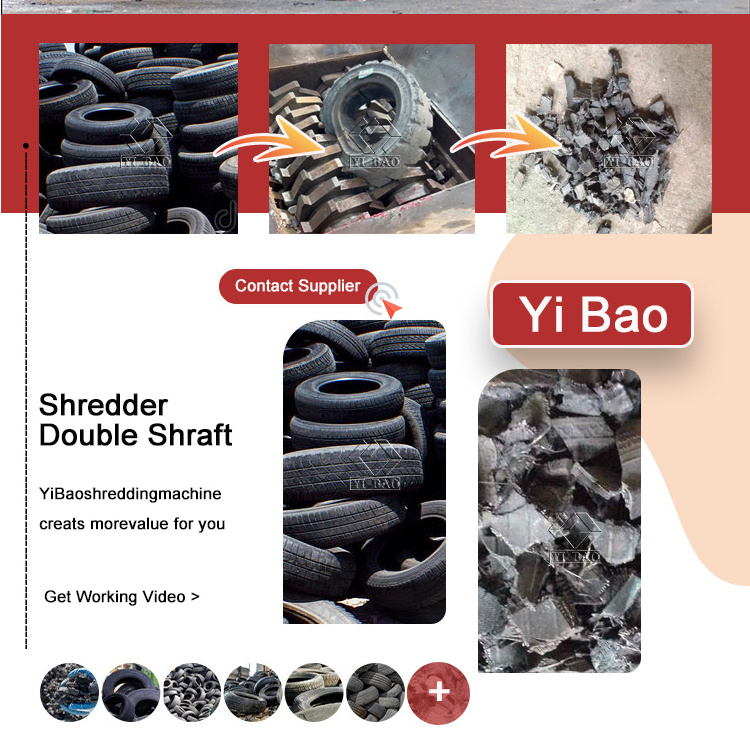

Double shaft shredder is a kind of machine used for material coarse crushing, generaly used in the crushing or recycing and reuseindustry for processing unprocessed raw materials or waste materlals shredder through the power system to drive the spindle todrive the blades rotor rotation, through the blades and bades to cut each other, Can shrd scran metal, plastic, tires, furnitre.

|

Model

|

|

YB600

|

YB800

|

YB1000

|

YB1200

|

YB1400

|

YB1600

|

Customized

|

||||||

|

|

KW

|

22*2

|

30*2

|

37*2

|

45*2

|

55*2

|

75*2

|

Customizable models according to customer needs

|

||||||

|

|

HP

|

30*2

|

40*2

|

50*2

|

60*2

|

75*2

|

100*2

|

|

||||||

|

Speed of revolution

|

|

8-20rpm

|

8-20rpm

|

8-15rpm

|

8-12rpm

|

8-12rpm

|

8-12rpm

|

|

||||||

|

Reducer

|

|

zq500

|

zq650

|

zq750

|

zq750

|

zq850

|

zsy400

|

|

||||||

|

|

|

Different types of reducers can be selected based on the customer's feeding situation (three shaft reducers, four shaftreducers,hard tooth reducers, planetary reducers, etc.) ,which affectsproduct prices

|

|

|

|

|

|

|

||||||

|

Blades quantity

|

|

20mm-30

|

40mm-20

|

50mm-20

|

60mm-20

|

70mm-20

|

80mm-20

|

|

||||||

|

|

|

The thickness and quantity of blades can be customized based on the shredding material and shredding effect

|

|

|

|

|

|

|

||||||

|

Bladesdiameter

|

|

220mm

|

300mm

|

400mm

|

450mm

|

500mm

|

600mm

|

|

||||||

|

|

|

he blades diameter, blade tooth shape and number of teeth of the blade can be customized based on the shredding material and

shredding effect ,which affects product prices. |

|

|

|

|

|

|

||||||

|

Bladesmaterial

|

|

The material of the blades can be customized according to the customer's shredding materials (55sicr、5crsi、9crsi、skd11、m6v、h13)

and actual usage, which affects the product price |

|

|

|

|

|

|

||||||

|

Discharge size

|

|

20-80mm

|

30-150mm

|

50-200mm

|

50-200mm

|

80-300mm

|

80-300mm

|

|

||||||

|

Feeding

hopper size

|

|

1x0.8m

|

1.2x1m

|

1.5x1m

|

1.8x1.2m

|

2x1.2m

|

2.5x1.5m

|

|

||||||

|

|

|

The size and appearance of the feeding hopper can be customized according to the customer's feeding situation

|

|

|

|

|

|

|

||||||

|

Weight(t)

|

|

2.5

|

4.5

|

6.5

|

8

|

10

|

13

|

|

||||||

|

Capacity(t/h)

|

|

0.5-0.8

|

0.6-1

|

1-3

|

1-3

|

2-5

|

2-5

|

|

||||||

|

Overall dimensions

|

|

2.8*1.6*1.8m

|

3.5*1.5*2.1m

|

4*1.7*2.4m

|

4.2*1.8*2.4m

|

4.5*2.2*2.4m

|

5.2*2.2*2.8m

|

|

||||||

Rorging material, spline link, adapt to large torque, long service life.

Connecting shaft system adopts direct connection mode to protect the main shaft and reducer, effectively reduce

resistance,vibration and friction.

resistance,vibration and friction.

PLC power control system is adopted to detect the running data and automatically control the positive and reverse functions

of the machine to keep the machine running more smooth.

of the machine to keep the machine running more smooth.

The blade is made of alloy material (such as 55SiCr,HD13,SKD-11), which is more wear-resistant, long service life and low

maintenance cost The diameter, width and number of teeth of the blade can be customized according to the material.

maintenance cost The diameter, width and number of teeth of the blade can be customized according to the material.

High-quality reducer, large torque, strong power.

The motor adopts all-copper core motor, which reduces energy consumption and has a long service life.

FAQ

Q1.What is the voltage?

A:Normally is 380V,50hz,3 phase,but we can change it according to customer's requirement, like 220V,415V,440V,600V and so on. shredder machine metal shredding machine scrap metal shredder wanrooe medical waste shredder with sterilizer

Q2.Do you inspect the finished products?

A:Yes, each step of production and finished products will be came out inspection by QC department before shipping.

shredder machine metal shredding machine scrap metal shredder wanrooe medical waste shredder with sterilizer

Q3.When is this machine can be deliveried?

shredder machine metal shredding machine scrap metal shredder wanrooe medical waste shredder with sterilizer

A:Normally 15 -20 working days

Q4.We want to visiting your factory first before order,if it is avaliable?

A:Yes,welcome to visit our factory,if our factory have ready machines in stock,we can help test it for you,you can see real

machine by your eyes and it will be the best for you to know our machine more

A:Normally is 380V,50hz,3 phase,but we can change it according to customer's requirement, like 220V,415V,440V,600V and so on. shredder machine metal shredding machine scrap metal shredder wanrooe medical waste shredder with sterilizer

Q2.Do you inspect the finished products?

A:Yes, each step of production and finished products will be came out inspection by QC department before shipping.

shredder machine metal shredding machine scrap metal shredder wanrooe medical waste shredder with sterilizer

Q3.When is this machine can be deliveried?

shredder machine metal shredding machine scrap metal shredder wanrooe medical waste shredder with sterilizer

A:Normally 15 -20 working days

Q4.We want to visiting your factory first before order,if it is avaliable?

A:Yes,welcome to visit our factory,if our factory have ready machines in stock,we can help test it for you,you can see real

machine by your eyes and it will be the best for you to know our machine more

Hot Searches