- Product Details

- {{item.text}}

Quick Details

-

Power:

-

8KW

-

Dimension(L*W*H):

-

4000*3000*2000mm

-

Weight:

-

2200

-

Product name:

-

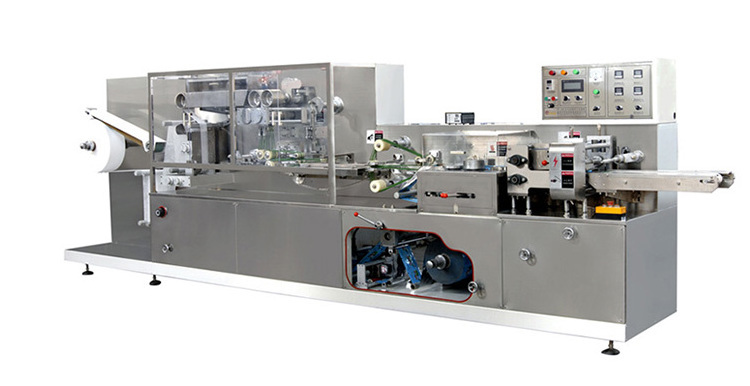

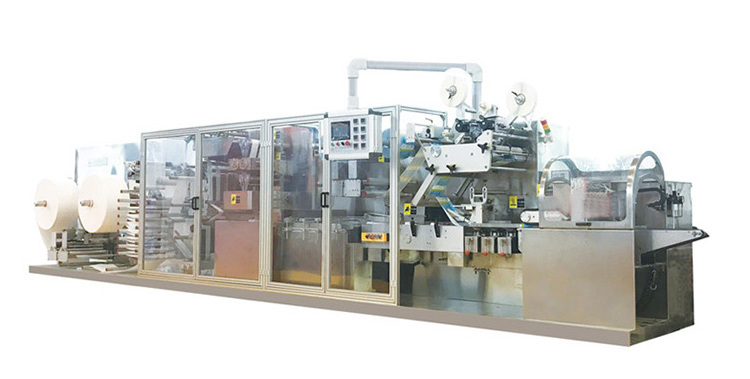

Wipes Machine Production Line

-

Wetting system:

-

Automatic Wetting Liquid

-

Product speed:

-

80~200bags/min

-

Type:

-

Single Piece Wet Tissue Machine (1pc/pack)

-

Materials:

-

Non-woven Fabric

-

Product type:

-

Wet Pipe

-

Packing film:

-

PET OPP

-

Wet Tissue Material:

-

30-80g/m2 Air Laid Paper

-

After-sales Service Provided:

-

Video technical support

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUGONG

-

Voltage:

-

220V

-

Power:

-

8KW

-

Dimension(L*W*H):

-

4000*3000*2000mm

-

Weight:

-

2200

-

Product name:

-

Wipes Machine Production Line

-

Wetting system:

-

Automatic Wetting Liquid

-

Product speed:

-

80~200bags/min

-

Type:

-

Single Piece Wet Tissue Machine (1pc/pack)

-

Materials:

-

Non-woven Fabric

-

Product type:

-

Wet Pipe

-

Packing film:

-

PET OPP

-

Wet Tissue Material:

-

30-80g/m2 Air Laid Paper

-

After-sales Service Provided:

-

Video technical support

-

Certification:

-

CE

Wet wipes production line:

1.

Control driving system:PLC,GOT operation interface,precision transmission by servo motor.

2.

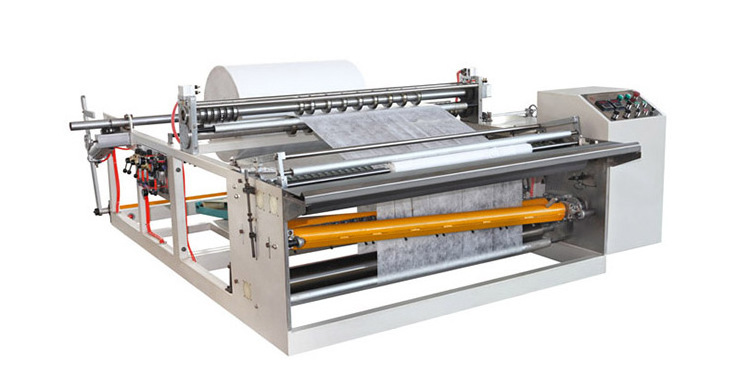

Unwinding mechanism:independent drive of unwinding device,automatic control of tension.

3.

Folding and traction mechanism:various adjustable folding ways,synchronous transmission by servo traction.

4.

Quantitative humidifying system:two sets of shower pipes,uniform humidifying in 2.5-4.0 times scope.

5.

Rotary cutting-off system:cut off by rolling cutter synchronously,cutting length controlled precisely,flexible and easy adjustable nonwovens length.

6.

Folding and conveying device:folded neatly by manipulators,synchronous and flexible transmission of wet wipes.

7.

Bag making and forming device:tension of the film and width and height of packing bags can be adjustable automatically.

8.

Packaging,cutting and sealing device:adopting Taiwan Rufong vertical sealing technology,advanced horizontal sealing of Chinese mainland.The seal is firm and beautiful.

9.

Safety guarantee system:Fixed,movable and closed preventive device.

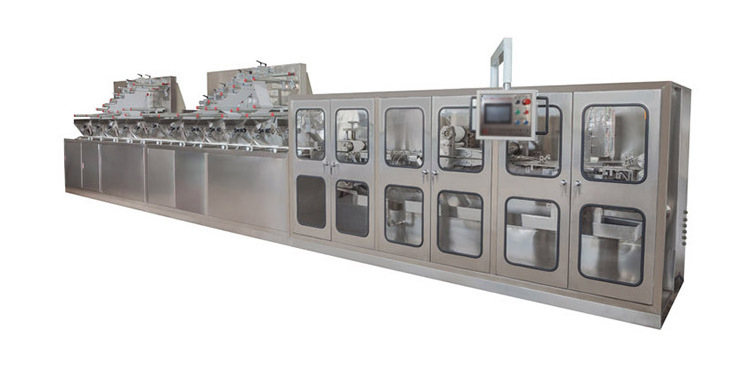

| Production speed | 270~400 cuts/minute; about 40-50 bags/minute |

| Number of slitting channels | 12 channels |

| Width | 1000-1520mm |

| Power supply | 380V 50HZ three-phase power |

| Total power | 13KW |

| Applicable raw materials | Spunlace non-woven fabric, hot-rolled non-woven fabric, dust-free paper, etc. |

| Material weight | 35-80 g/m2 |

| Folding method | "Z"-shaped folding (with or without extraction) |

| Humidification method | Preset automatic metering humidification |

| Humidification accuracy | +5% |

| Machine net weight | 9000kg |

| Humidification mixing system | Double mixing barrel with agitator |

| Mixing barrel size | 800×800 (mm, diameter×height) |

| Capacity | 400 liters * 2 pieces |

1. Packaging:

Packed by standard import & export wooden cases or carton boxes.

2. Shipping:

By logistics; by automobile; by train; by shipping; by air etc.