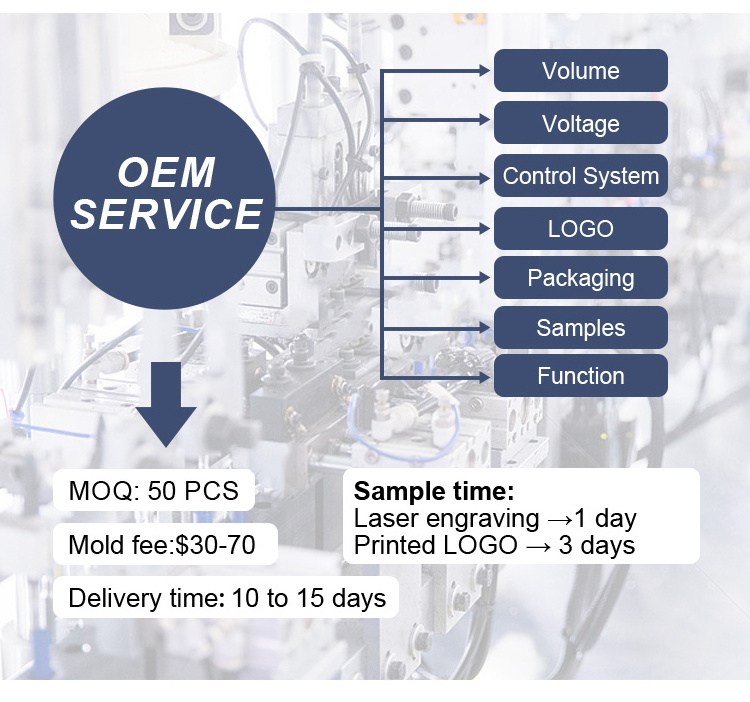

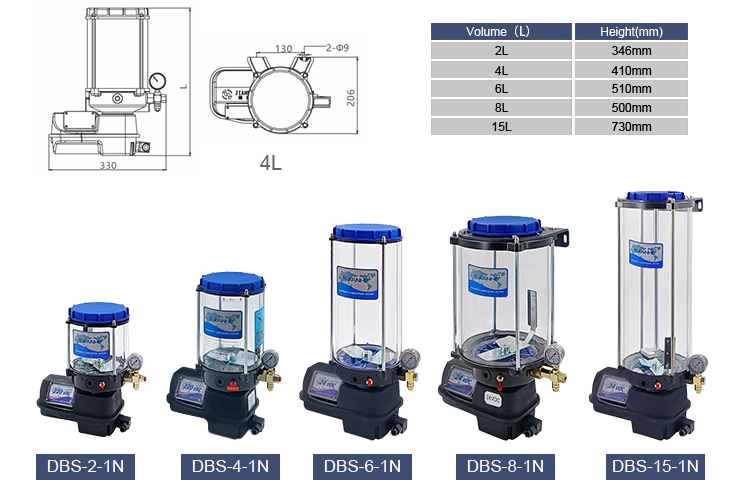

Lubrication pumps can be customized from 2-15 liters capacity and explosion-proof tanks can be customized,If you need a larger capacity you can contact us for customization.

- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 years

-

Brand Name:

-

JIANHE

-

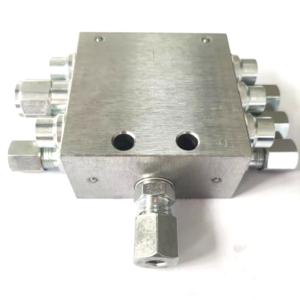

Model Number:

-

DBS Series

-

Place of Origin:

-

Zhejiang, China

-

Horsepower:

-

NONE

-

Cable Length:

-

NONE

-

Outlet Size:

-

M10 or R1/4 as Customer needs

-

Power:

-

50W/80W, Electric

-

motor:

-

as Customer needs

-

Usage:

-

Grease

-

Grease Viscosity:

-

NLGI 000#---3#

-

Remarks:

-

Prices are for reference only, contact us for lower and better prices

Quick Details

-

Application:

-

Automotive Industry, Machining, Excavator, wheel loaders

-

Pressure:

-

25mpa, High/Low Pressure

-

Voltage:

-

12VDC/ 24VDC/110VDC/220VAC/ 380VAC

-

Warranty:

-

1 years

-

Brand Name:

-

JIANHE

-

Model Number:

-

DBS Series

-

Place of Origin:

-

Zhejiang, China

-

Horsepower:

-

NONE

-

Cable Length:

-

NONE

-

Outlet Size:

-

M10 or R1/4 as Customer needs

-

Power:

-

50W/80W, Electric

-

motor:

-

as Customer needs

-

Usage:

-

Grease

-

Grease Viscosity:

-

NLGI 000#---3#

-

Remarks:

-

Prices are for reference only, contact us for lower and better prices

Customized services

Volume Customization

System customization—Progressive Lubrication System

For small- to medium-sized machines that require continuous lubrication

Progressive systems provide continuous lubrication as long as the pump is in operation. Once the pump stops, the pistons of the

progressive metering device will stop in their current positions. When the pump starts supplying lubricant again, the pistons will

carry on where they left.

progressive metering device will stop in their current positions. When the pump starts supplying lubricant again, the pistons will

carry on where they left.

Therefore, the progressive circuit of one outlet of the pump will stop when only one lubrication point is blocked. The blockage

serves as a means of control and forces personnel to service the system.

serves as a means of control and forces personnel to service the system.

Benefits

●

Continuous lubrication - Delivers frequent and measured amounts of lubricant to each lubrication point.

●

Reliable monitoring and control - Easy system monitoring and simple blockage control, integrated system control and monitoring.

●

Effective in harsh conditions - Potentially high lubrication point back pressure, dirty, wet or humid environments (including ATEX/ EEX), and low temperatures.

Applications

●

Construction machines (concrete pumps, mortar pumps, loaders, excavators, trenchers)

●

On-road trucks (snow removal, waste press)

●

Agricultural machines (harvesters, balers, manure spreaders, sugar cane loaders)

●

Wood reclaimers

●

Material handling (reach stackers, crane carts)

●

Asphalt mixing plants

●

Wind turbine generators

System customization—Single Line Lubrication System

For small-to-medium line length and almost all lubricants

Regardless of the application, the principle of single-line lubrication remains the same: a central pump station automatically

delivers lubricant through a single supply line to the lubricant metering device. Each metering device serves only one lubrication

point and may be adjusted to deliver the precise amount of grease or oil required.

delivers lubricant through a single supply line to the lubricant metering device. Each metering device serves only one lubrication

point and may be adjusted to deliver the precise amount of grease or oil required.

Systems can service one machine, different zones on one machine or even several separate machines

Benefits

●

Easy to understand, install and maintain.

●

Suitable for almost all lubricants.

●

Easy system expansion.

●

Reliable.

●

System continues to operate if one point becomes blocked

●

Able to pump long distances and within a wide temperature range

Applications

●

Machine tools

●

Automation

●

Printing machines

●

On/Off-road machines

●

Construction and forestry machines

●

Cement industry

●

Oil and gas industry reciprocating compressors

System customization—Dual Line Lubrication System

For use on large machinery, effective in harsh conditions

Dual-line systems dispense a precise, metered amount of lubricant to up to 2 000 lubrication points over long distances up to 120

m (131 yd) and more. Even if one pair of outlets becomes blocked inside one metering device, dual-line systems provide sufficient

lubrication for the rest of the system’s lubrication points. Lubricant volume can be metered individually for each pair of outlets

and can be monitored visually or electrically.

m (131 yd) and more. Even if one pair of outlets becomes blocked inside one metering device, dual-line systems provide sufficient

lubrication for the rest of the system’s lubrication points. Lubricant volume can be metered individually for each pair of outlets

and can be monitored visually or electrically.

Benefits

●

Flexible - simple to design, easy to extend or reduce.

●

Reliable - precise, metered amount of lubricant, to up to 2000 lubrication points over long distances up to 120 m

●

Effectively in harsh conditions including potentially high lubrication-point back pressure, dirty, wet or humid environments and low temperatures

●

Variety of applications

Applications

●

Heavy industry

●

Metalworking plants

●

Pulp and paper production

●

Mining and mineral processing

●

Power plants

●

Cement factories

System customization—Multi Line Lubrication System

The right lubricant, in the right quantity, at the right time, to the right lubrication point

Centralized automatic lubrication systems are an effective way to increase machine availability while reducing reliance on scarce

talent. These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and

optimizing bearing and machinery service life.

talent. These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and

optimizing bearing and machinery service life.

Designed to lubricate individual machines or complete plants, automatic lubrication systems provide proper, precise lubricant

replenishment to all required points, enabling a range of benefits in the process

replenishment to all required points, enabling a range of benefits in the process

Benefits

●

Significant savings in repair and spare costs.

●

Increased machine reliability.

●

Up to 50% savings in lubricant costs due to accurate timing and dosing of lubricants.

●

Fewer shutdowns and production losses.

●

Reduced environmental impact

●

Greater workers' safety

Applications

●

Machine tools

●

Automation

●

On/Off-road machines

●

Construction, agriculture and forestry machines

●

Mining and cement industry

●

Railroad applications

●

Wind energy

Other Customized Services

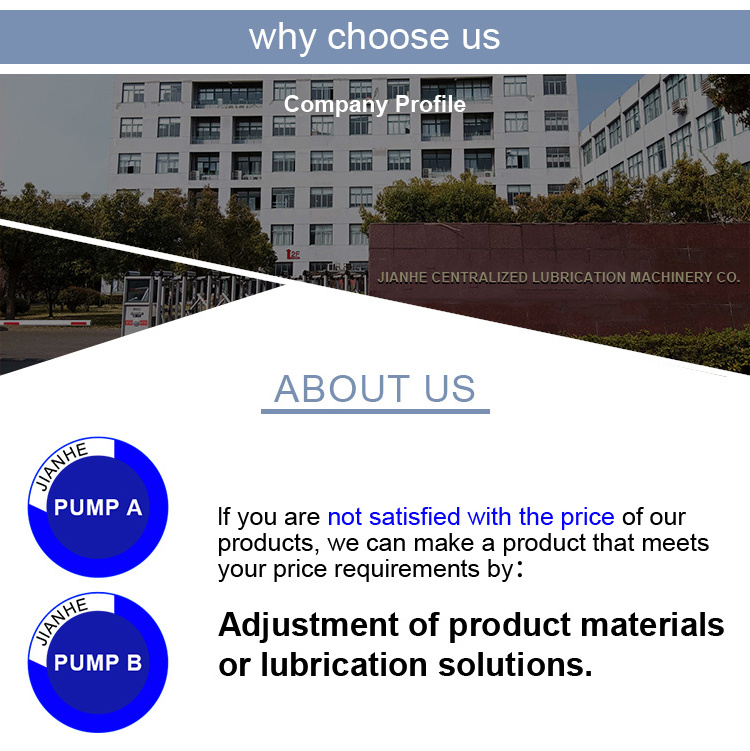

LOGO Customization

We can customize your logo free of charge, whether on pumps, distribution block or lubrication accessories.

Packaging Customization

We can customize wooden crates and pallets to protect your purchases for safety and ease of shipping!

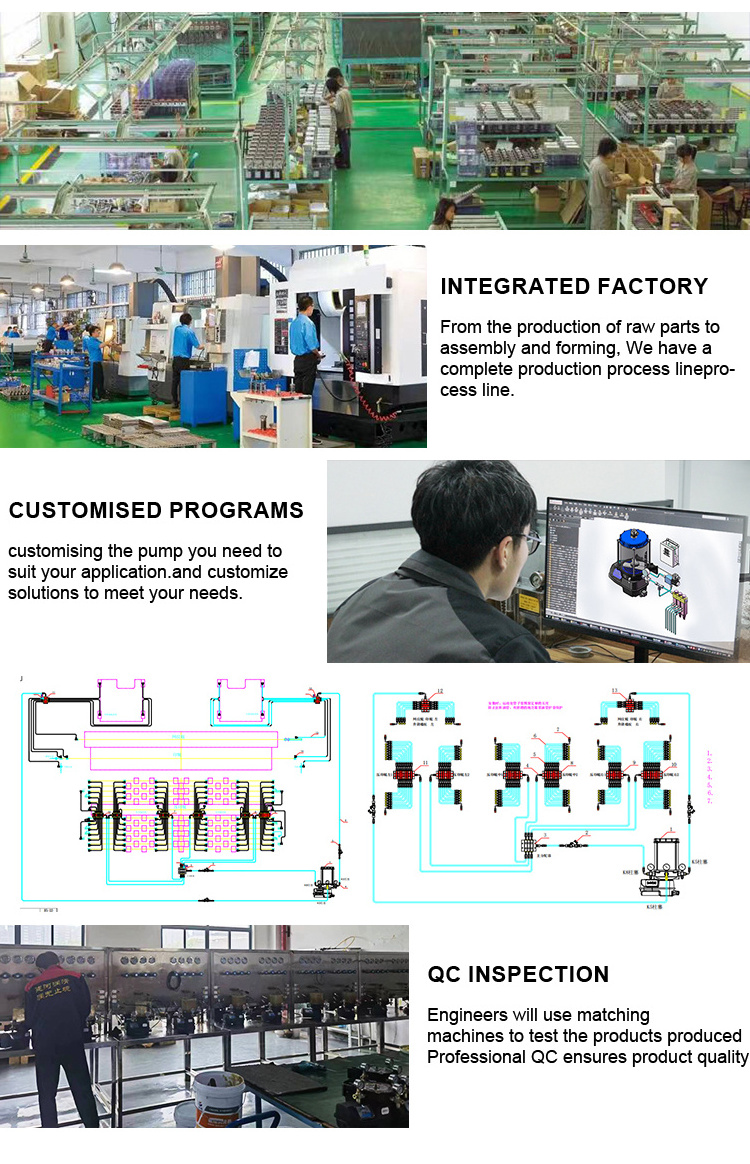

Factory Advantage

Advantage 1:

Jianhe Factory

expanded its plant size and production facilities in 2023, covering an area of 5,000 square meters and employing more than 50 people.

Advantage 2:

From the production of raw parts to assembly and forming, We have a complete production process line.

Advantage 3:

Each product is tested and inspected to ensure the quality of the product

Advantage 4:

JIANHE has a separate warehouse to stock the products and can deliver them from stock for small orders

Advantage 5:

JIANHE regularly attends exhibitions and provides lubrication services to many customers.

|

|

Hot Searches