The stainless steel rotary vibration screen is simple and can be dismounted assemble and be dismounted and

cleaned easily.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/415V/450V

-

Dimension(L*W*H):

-

400*380*100mm

-

Weight:

-

200 KG

-

Product name:

-

Rotary Vibrating Screen

-

Keyword:

-

Rotary Vibrating Separator

-

Material:

-

Stainless Steel 304

-

Usage:

-

Fine Particles Screening

-

Function:

-

Screening\separation\sorting\sieving

-

Advantage:

-

High Sieving Precision

-

Color:

-

Customers' Request

-

Name:

-

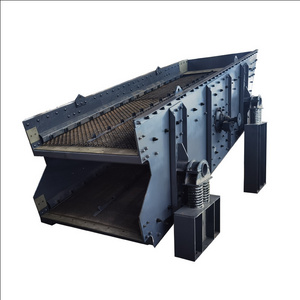

Linear Vibrating Sieve Screen Machine

Quick Details

-

Type:

-

Circular

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hengyun

-

Voltage:

-

220V/380V/415V/450V

-

Dimension(L*W*H):

-

400*380*100mm

-

Weight:

-

200 KG

-

Product name:

-

Rotary Vibrating Screen

-

Keyword:

-

Rotary Vibrating Separator

-

Material:

-

Stainless Steel 304

-

Usage:

-

Fine Particles Screening

-

Function:

-

Screening\separation\sorting\sieving

-

Advantage:

-

High Sieving Precision

-

Color:

-

Customers' Request

-

Name:

-

Linear Vibrating Sieve Screen Machine

DESCRIPTION

Round Vibrating Screen Vibrating Machine

Rotary vibration screen is a high precision fine powder screening machine. The working principle of vibrating screen is that the unbalanced weight dropper installed on the top and bottom ends of motor to change the rotation motion of motor to horizontal, vertical and inclined three-dimensional motions, and then passes this motion to screen surface, achieving the purpose of classification, filtering and removing impurities.

APPLICATION

Chemical industry: resin pigment, calcium carbonate, decorative coatings, medicine, grease, paint, palette, etc. Abrasive material and ceramic industry: building sand, mica, alumina, silica sand, abrasive, refractory material, slurry, etc. Food industry: sugar, salt, alkali, flour powder, nut powder, whey protein powder , maltodextrin , flavors , sucralose , xanthan gum, soy lecithin ,farina, gourmet powder, starch, milk powder, yeast powder, pollen, food additive, bean milk, juice, etc. Paper-making industry:coated slurry, exhaust liquid, paper making liquid and waste water reclamation, etc. Metallurgy and mining industry: quartz sand, sand, ore, titanium oxide, zinc oxide, etc. Mechanical industry: casting sand, charcoal, grafito, powder metallurgy, electromagnetic material and metal powder, etc

|

Model

|

Diameter(mm)

|

Deck

|

Screen mesh area(mm)

|

Mesh size(mesh)

|

Max particle size(mm)

|

Power(kw)

|

|

S494-B

|

Φ400

|

1-5

|

Φ380

|

3-500

|

<20

|

0.25

|

|

S496-B

|

Φ600

|

|

Φ600

|

3-500

|

<20

|

0.6

|

|

S498-B

|

Φ800

|

|

Φ750

|

3-500

|

<30

|

0.6

|

|

S4910-B

|

Φ1000

|

|

Φ900

|

3-500

|

<30

|

0.8

|

|

S4912-B

|

Φ1200

|

|

Φ1100

|

3-500

|

<30

|

1.5

|

|

S4915-B

|

Φ1500

|

|

Φ1450

|

3-500

|

<50

|

2.2

|

|

S4918-B

|

Φ1800

|

|

Φ1750

|

3-500

|

<50

|

2.5

|

|

S4920-B

|

Φ2000

|

|

Φ1950

|

3-500

|

<60

|

2.5

|

SUITABLE FOR POWDER,LIQUID OR TINYGRANULAR PRODUCTS.

High precision fine powder screening machine

Hot Searches