- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

plastic injection parts

-

Material:

-

ABS,PP,PEEK, PC,PMMA, POM etc.

-

Surface finishing:

-

Original, Matte or custom surface texture

-

Cavity:

-

Custom

-

Color:

-

White,Black, Grey or custom color

-

Years in industry:

-

23 years

-

Product name:

-

plastic injection parts

Quick Details

-

Processing Service:

-

Moulding

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Mogel

-

Model Number:

-

plastic injection parts

-

Material:

-

ABS,PP,PEEK, PC,PMMA, POM etc.

-

Surface finishing:

-

Original, Matte or custom surface texture

-

Cavity:

-

Custom

-

Color:

-

White,Black, Grey or custom color

-

Years in industry:

-

23 years

-

Product name:

-

plastic injection parts

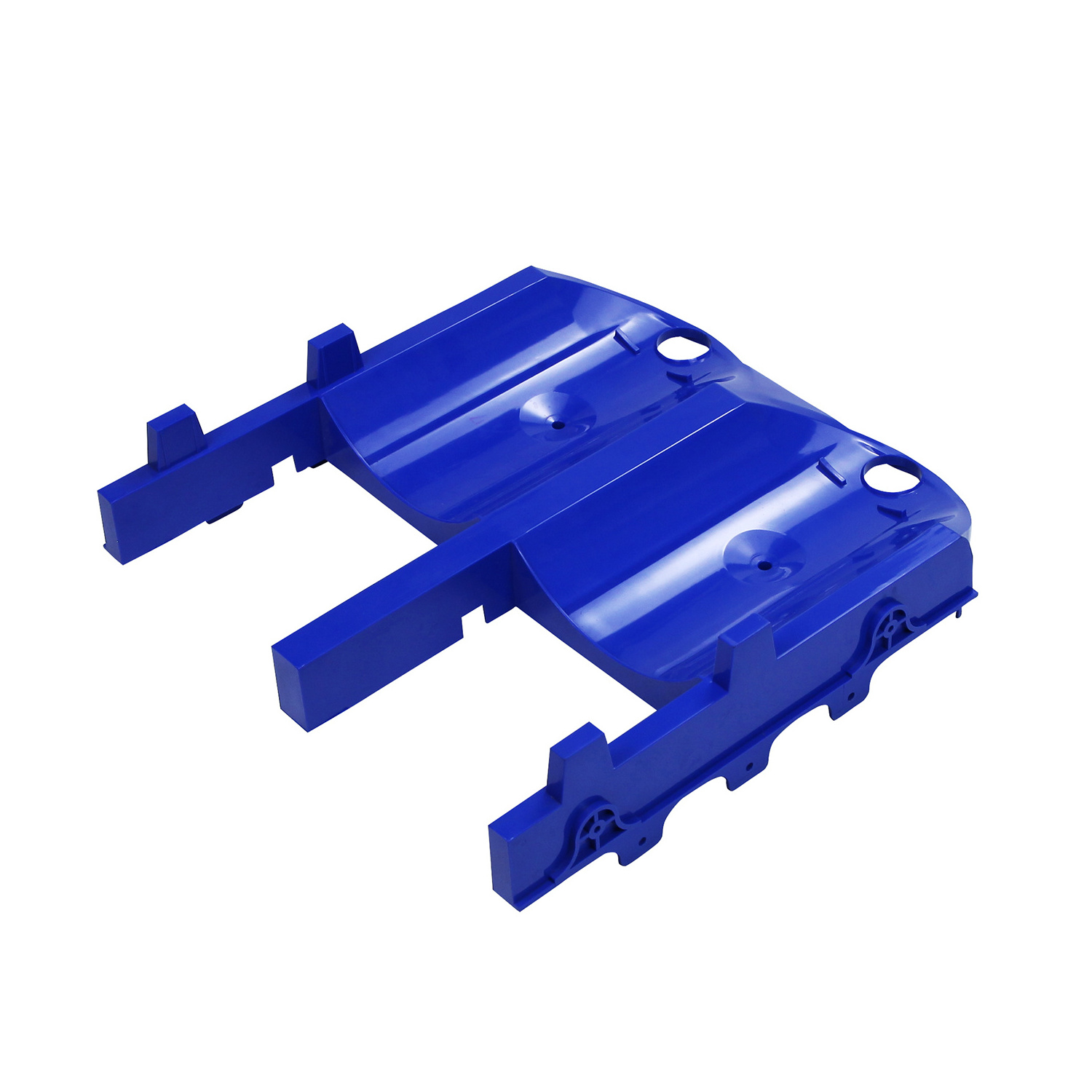

china manufacturer production injection molding plastic parts custom small abs plastic parts

| Description of product |

| Product range | Mold design, mold making and produce plastic parts |

| Processing Craft | Mold fabrication, Injection etc; |

| Material | ABS,BMC, SMC, AS,PP,PPS,PC,PE,POM,PMMA,PS,HDPE,TPE,TPU etc |

| Surface finish | Polishing finish,Texture Finish,Glossy Finish,Painting,Slik print,Rubber Painting etc |

| Color | RAL/PANTONE color |

| Size | according to the drawing |

| Mold Standard | DME,LKM,FUTA,HASCO etc. |

| Advantages | Competitive price & Fast Delivery & Good quality |

| Mould Base | as per customer's requirement |

| Delivery time | 10-15 days after placed order |

| Tolerance | 0.01~0.1mm; |

| File Format | Solidworks,Pro/Engineer,Auto CAD,PDF,JPG |

| Quality Control | Conducted by ISO9001 System and PPAP Quality control documents |

| Inspection | IQC, IPQC,FQC,QA |

| Application | All kinds of plastic injection parts being used in a variety of industrial application. |

| Service |

Warm and quick response service provided by the professional Export Sales Team with many years' experience in handling exports to the US, Europe, Japan and other countries and regions. |

| Product details |

We can offer the full range of service from mold designing, making, plastic part molding to printing, assembly, package, and shipping arrangement.

- In the service of plastic injection, Ideal plastic is more than just an injection molder.

- We provide solutions to manufacturing from start to finish.

- Our expertise enables us to provide clients with superior product by providing the

- highest quality in design, development, and solutions for precision injection molding and related manufacturing.

- We have over 10 years production experience.

Custom Plastic Injection Molding Services

Precision Plastic Injection Molding Services

We offers comprehensive custom plastic injection molding services to a wide range of industries. From low volume work to high volume production runs, we have the expertise and facilities to meet our customers’ contract manufacturing needs. We offer two shot, sandwich and insert injection molding as well as micro and gas assist molding. We have both 10K and 100K clean room manufacturing facilities for those customers in the medical, pharmaceutical, food, beverage and electronics industries. Our comprehensive plastic injection molding abilities include machines with clamping forces from 18 to 3,000 tons, allowing us to produce

ne

arly

any plastic part including micro parts, thin-walled parts, and large components that require multiple shots.

We can source and mold any grade of material from typical commodity grade plastics, to engineering, functional, and structural grade materials in a variety of colors and formulations. In addition to injection molding, we offer many secondary services including sonic vibration, RF welding, hot stamping, etching, printing, plating, and packaging. Our manufacturing processes are highly automated, which allows us to run a precise and efficient production floor with minimal overhead costs. These capabilities allow us to provide fast and cost competitive manufacturing services to our customers without sacrificing precision and quality.

| Our Service |

| Our Advantage |

1.Small details make big difference. We promise:All the parts from our company have no sharp edge.

All dimensions

are

controlled according to your drawings

. Every product will be

fully inspected and

carefully packed to prevent the bump and rust in transit .

2. The craftsmanship of all parts we machined is controlled rigorously, Every product has its own process card and process chart.

3. Our quality inspection procedure is quite strict.it must self-inspected during production, we have flow inspectors and professional inspectors.

4. Each size of product must be tested one

by

one after completing production and provide quality report.

5. The most important point, we are the entity factory, not trading company. Price is the composition of the actual product quality price. Quality can guarantee more controllable higher than trading company. The price is

competitive

, at least reducing the trade company's service fee.

6.We have many years of export experience, exports to the US,Europe, Japan and other countries and regions.

7. Our team are more professional . We have more reasonable price and better quality controlling than trade company. And our language ability is also diversified.