- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Brightcnc

-

Voltage:

-

220v

-

Dimension(L*W*H):

-

1900*1350*1400mm

-

Weight (KG):

-

1300

-

Name:

-

Busbar Machine

-

Application:

-

Switchgear Cabinet Switch Board

-

Processing material:

-

Copper Aluminum Bus Bar

-

After-sales Service Provided:

-

Video Technical Support

-

Cutting type:

-

Flat Blade Busbar Machine

-

Bending type:

-

CNC Control Busbar Machine

-

Punching range:

-

4.3~30mm

-

Color:

-

Customer's Requirement

-

Package:

-

Wooden Box

-

MOQ:

-

1 Set

Quick Details

-

Max. Thickness (mm):

-

15 mm

-

Max. Width (mm):

-

160 mm

-

Marketing Type:

-

New Product 2024

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Brightcnc

-

Voltage:

-

220v

-

Dimension(L*W*H):

-

1900*1350*1400mm

-

Weight (KG):

-

1300

-

Name:

-

Busbar Machine

-

Application:

-

Switchgear Cabinet Switch Board

-

Processing material:

-

Copper Aluminum Bus Bar

-

After-sales Service Provided:

-

Video Technical Support

-

Cutting type:

-

Flat Blade Busbar Machine

-

Bending type:

-

CNC Control Busbar Machine

-

Punching range:

-

4.3~30mm

-

Color:

-

Customer's Requirement

-

Package:

-

Wooden Box

-

MOQ:

-

1 Set

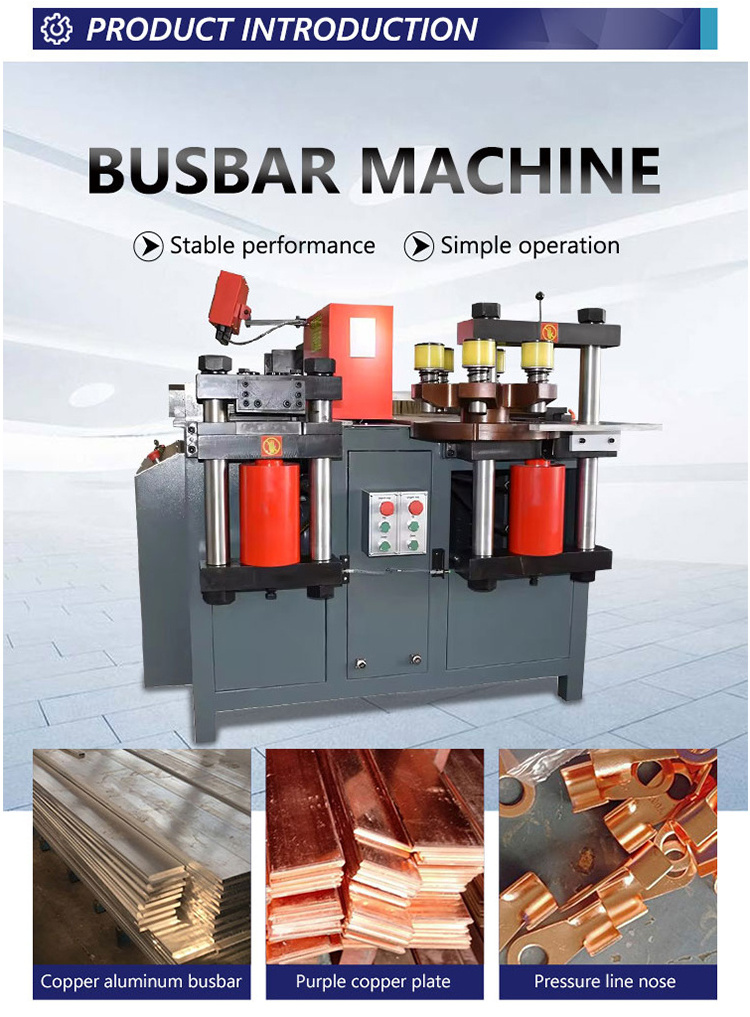

Cnc High Grade New Design Hydraulic Bus Bar Cutting Punching Bending Metal Processing Busbar Machine

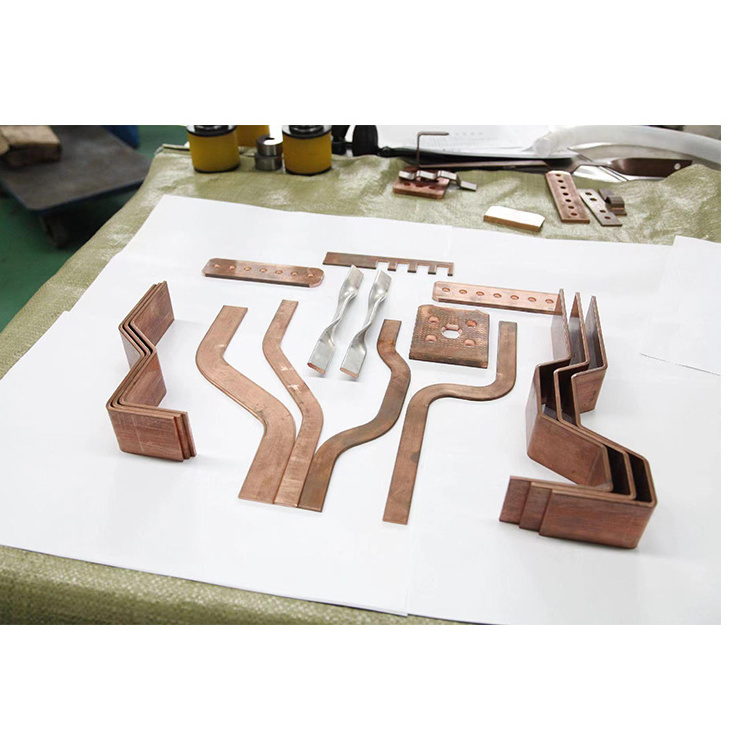

The machine is installed with punching, cutting, bending three processing stations, the main function for processing different specifications of copper, aluminum bus. When working, you need to choose the corresponding processing station, you can easily and quickly cut, punch (round hole, long round hole), bend flat bending, vertical bending.U-bend, embowel, flatten, twist, pressure cable joint and other different processing.

Punch function

Shear function

Bending function

Punch sample

Shear sample

Bent sample

Embossed piece

Corner cutting sample

Small bent sample

Twist hemp pattern piece

Copper bar sample

One molding sample

No burrs, no collapse Angle

Shear station adopts double column shear structure, smooth section, ano waste, no burr,no collapse Angle.

Six-mode rotary table

The hole station is a six-mode rotary table, no need to change the mold,reduce the misoperation caused by frequent mold change, and reduce the damage rate of the mold. The turntable is the whole work piece, which ensures the alignment of the upper and lower die, improves the concentricity of the die, and greatly improves the service life of the die.

Bending station

The bending station adopts a closed bending structure, which makes it more uniform in the processing of flat bending and embossing. The repeated positioning accuracy in mass production is greatly improved.

Two-layer operation

The bending station adopts a double-layer workbench, which realizes the simultaneous work of three stations without affecting each other in the real sense.

3mm thick steel plate welding

The hydraulic oil tank is welded with 3mm thick steel plate and treated withphosphating, so that the hydraulic oil will not deteriorate in long-term use.

Built-in trim

Using Japan Panasonic PLC control, bending Angle CNC control, and has the memory function. Each station can be set automatic downtime, for the enterprise to save a lot of electricity expenses. The system comes with fine tuning function, which is more convenient to use.

|

MBR-303 Parameters

|

|

|

||

|

|

Max. Cut Force

|

500kn

|

||

|

|

Max. Cut Thickness

|

15mm

|

||

|

|

Max. Cut Width

|

160mm

|

||

|

|

Max. Punch Force

|

300kn

|

||

|

|

Punch Diameter

|

4.3∅~30mm∅

|

||

|

|

Max. Thickness

|

15mm

|

||

|

|

Max. Width

|

160mm

|

||

|

|

Horizontal Max. Punch Force

|

300kn

|

||

|

|

Horizontal Max. Thickness

|

12mm

|

||

|

|

Horizontal Max. Width

|

150mm

|

||

|

|

Vertical Max. Width

|

10 x 100

|

||

|

|

Vertical Max. Angle (Degree)

|

90°

|

||

|

Accuracy

|

±1°

|

|

||

|

Repeat Bend Precision

|

±0.2°

|

|

||

|

Dimension

|

1900*1350*1400mm

|

|

||

|

Motor Power

|

4kw*3

|

|

||

|

Weight

|

1300kgs

|

|

||

Distribution box

Power supply plant

Steel frame house

Dockyard

About us

Jinan bright group co.,ltd. is a professional manufacturer of busbar processing machines, copper and aluminum row processing machines, and busway processing equipment. With many years of production experience, mature technology, high output, fast delivery, and quaranteed after-sales service .

Professional Advantage

Many years of professional production and export experience.Cooperation with the largest customers from some countries.

Quality Assurance

All the products have the certificate of lSO and CE approval, Guaranteed quality.

Price Advantage

Good quality,reasonable price, on time shipping and best service for each customers.

Perfect Quality Control

We have our own professional testing equipment Strict quality control system provide high-quality products and services for you.

Customized Service

We can tailor it to each customer's requirements.

After-Sale Advantages

Long time guarantee period and 24 hours online service.

01

What information should the customer provide to get an accurate quotation from us?

A:

The customer provides the corresponding industrial voltage requirements, the maximum width and thickness of the processed copper and aluminum bars, the required quantity, etc.

02

What is the payment term?

A: The payment term is 40% down payment, and 70% before shipment(T/T mode), we also accept other payment term, like L/C, DA, D/P etc.

03

What is the delivery time?

A: Normally the delivery time of the machine is 10 days after receive down payment.

04

What is the warranty period of the machine?

A: The warranty period is two year since the date of B/L.

05

What about the package?

A: The machine will be packaged by multilayered plastic wrap for anti-humidity on the sea. The strong steel wire ropes will be used for fix the machines in container to avoid any damage in transportation.

06

What is your shipping way ?

A: Express (DHL,FedEx,TNT),By air ,Or Sea. We will choose one shipping way to suit customers

Hot Searches